1050 aluminum strip, known for its excellent electrical conductivity (over 60% IACS), is widely used in transformer windings. Also referred to as 1050 aluminum transformer foil, its primary applications include winding for dry-type and oil-immersed transformers.

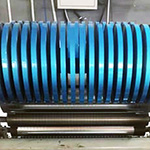

The thickness of 1050 aluminum foil strip ranges from 0.2 mm to 3.0 mm, and the width ranges from 30 mm to 1600 mm. Single-layer or double-layer aluminum strips can be provided to effectively reduce coil leakage flux and enhance its insulation performance.

1050 O aluminum strip is widely used for transformer windings due to its excellent electrical conductivity and other beneficial properties.

1050 O aluminum strip is a high-purity annealed aluminum material specifically designed for transformer winding applications. These aluminum strips are favored in both dry-type and oil-immersed transformers for their outstanding conductivity, formability, and corrosion resistance. They meet the industry's stringent standards for transformer efficiency and durability.

Specifications for 1050 Transformer Aluminum Strip

| Product name | Aluminium Strip for transformer winding |

| Grades | 1050, 1350, 1060, 1070 |

| Temper | O |

| Specification |

Thickness:0.2-3.5mm Width:20-1400mm |

| Quantity tolerance | ±10% |

| Edge Type | Slit or Round, customizable according to customer requirements |

| Paper Core Inner Diameter | Ø150 mm, Ø300 mm, Ø400 mm, Ø500 mm (special sizes available upon request) |

| Surface Treatment | Smooth surface, free of scratches and impurities |

| Surface Quality | Smooth and burr-free surface, no scratches, edges can be chamfered to reduce the risk of damage to the insulation layer |

| Application | Transformer winding |

| Packaging | Wooden Pallet |

Features of 1050 Transformer Aluminum Strip

- Electrical and Thermal Conductivity: 1050 aluminum strip has high electrical conductivity and excellent conductive properties, making it suitable as a conductive material in transformer windings. At the same time, it has good thermal conductivity, which helps dissipate heat effectively and further enhances transformer operating efficiency.

- Corrosion Resistance: 1050 aluminum strip has good corrosion resistance, making it suitable for use in transformer operating environments and effectively extending its service life.

- Flexibility: 1050 in O temper (soft temper) is soft and easy to process, making it convenient for winding complex coil structures.

- Appearance: 1050 aluminum strip has a smooth appearance and is easy to process, providing high-quality material for transformer windings.

- Performance: Due to its excellent electrical and thermal conductivity, 1050 aluminum strip is commonly used as a supporting material for transformer windings, effectively reducing transformer losses and improving overall performance.

Applications of 1050 Transformer Aluminum Strip

In transformer manufacturing, 1050 O aluminum strip is mainly used for winding coils. Its high conductivity and ductility allow for precise winding, which is critical for controlling inductance and capacitance values. It can also be used as a connecting material between coil turns, ensuring stable electrical and mechanical connections.

In the transformer manufacturing process, the 1050 aluminum strip, with its excellent conductivity and high purity, is an ideal material for transformer windings, especially as a connection material for winding coils.

Winding Coils

- Material Selection: The 1050 O-type aluminum strip is chosen for winding transformer coils due to its excellent conductivity and good plasticity. The O-type treatment of the aluminum strip provides good ductility, suitable for precise winding on transformer coils.

- Winding Process: According to transformer design requirements, the 1050 aluminum strip is precisely wound onto the windings. This winding method effectively controls the values of inductance, mutual capacitance, and distributed capacitance to meet the performance requirements of the transformer.

Connection Methods

- Winding Connections: The aluminum strip is used not only for winding but also for connections between coil turns. The use of aluminum strips for connections ensures stable electrical and mechanical connections between windings.

- Other Connection Methods: In addition to using aluminum strips for connections, other methods such as tin soldering or welding can also be employed in transformer production. These methods can further ensure secure connections and electrical performance between windings.

1050 Aluminium Strip Chemical Composition

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.5 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.0200 | 0.0022 | 0.0039 |

Mechanical Properties of 1050 Aluminum Foils and Strips for Transformers

| Alloy | Thickness /mm | Temper | Tensile strength MPa | Elongation (%) |

| 1050, 1060, 1070, 1350 | 0.08-0.20 | O | 60-95 | ≥20 |

| gt;0.20-3.00 | ≥25 |

Comparison of Common Transformer Aluminum Strip Grades

1050 vs 1060: Both belong to the pure aluminum series. 1050 has slightly higher aluminum content (99.5% vs 99.6%) and better conductivity; 1060 has slightly higher strength, suitable for applications with higher mechanical performance requirements.

| Aluminum Strip Grade | Minimum Aluminum Content | Electrical Conductivity | Mechanical Properties | Formability and Workability | Application Characteristics |

| 1050 Transformer Aluminum Strip | ≥99.5% | Excellent conductivity, suitable for low-voltage electrical applications | Lower strength, suitable for applications with low mechanical performance requirements | Good formability, strong cold working performance, suitable for stamping, bending, stretching, etc. | Mainly used in low-voltage transformers, capacitors, cable sheathing, radiators, etc., where conductivity and corrosion resistance are important |

| 1060 Transformer Aluminum Strip | ≥99.6% | Good conductivity, slightly lower than 1070 and 1350 | Slightly stronger than 1050, suitable for applications requiring certain mechanical strength | Good workability, suitable for winding and automated processing equipment | Commonly used in transformer coils, electronic foils, power devices, balancing conductivity and structural strength |

| 1070 Transformer Aluminum Strip | ≥99.7% | Very high conductivity, among the best in pure aluminum series | Lower strength, but suitable for soft temper processing | Extremely flexible, excellent ductility, suitable for making ultra-thin strips or foils | Suitable for high-end electrical products requiring extremely high conductivity, such as ultra-low-loss transformers, electrical connection strips, etc. |

| 1350 Transformer Aluminum Strip | ≥99.5% (Electrical Grade) | Extremely high conductivity (above 61% IACS), meets international electrical standards | Comprehensive strength is better than general pure aluminum, and can be enhanced by heat treatment | Easy to process, suitable for hot rolling, cold rolling, extrusion, welding, and other forming methods | Widely used in high-voltage transformer windings, cable conductors, electrical busbars, and is a commonly used aluminum strip in international electrical standards |

Advantages Over Other Alternatives

- Cost-Effective: Lower material cost than copper while maintaining over 60% conductivity.

- Durability: Corrosion and thermal stress resistance make it suitable for long-term use.

- Customizable: Adjustable thickness, width, and edge treatments to suit specific transformer designs.

Haomei Other Alloy Transformer Aluminium Strips

-

1060 Transformer Aluminium Strips

Annealed or O-state 1060 aluminum strip has higher flexibility and ductility, and its conductivity is better than 61.5% IACS.

-

1070 Transformer Aluminium Strips

1070 aluminum strip has a conductivity of more than 62.7% IACS, and its thickness is generally 0.1mm to 3.5mm, which can adapt to the design requirements of different transformer windings and provide flexible options.

-

1350 Transformer Aluminium Strips

1350 aluminum foil strip has a conductivity better than 62% IACS. It is widely used in transformer windings, especially oil-immersed and dry transformers. Its high conductivity ensures the high efficiency and stability of the transformer.