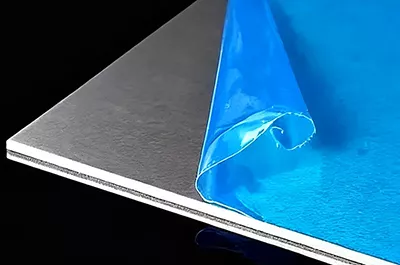

5086 h111 aluminum plate sheet

What is 5086 H111 material?

5086 H111 is a specific temper designation for 5086 aluminum alloy. 5086 alloy is known for its high strength, excellent corrosion resistance, and good machinability.

5086 H111 achieves a balance between strength and ductility. Compared to other harder tempers, it is easier to machine and form.

5086 H111 is a variant of the 5086 alloy, with a temper that offers medium strength and excellent corrosion resistance, making it suitable for marine and industrial applications.

5086-H111 is an aluminum-magnesium alloy, well known for its outstanding corrosion resistance (especially in marine environments), medium strength, and good formability. The "H111" temper indicates that the alloy has undergone stress relief after cold working, which enhances its flexibility and durability compared with harder tempers.

- Characteristics: low density, high tensile strength, high elongation

- Advantages: excellent corrosion resistance, good weldability, medium strength

- Applications: ship components (such as hull structures), automotive weldable parts, transportation equipment (such as C82 coal cars, tank cars), pressure vessels, drilling equipment, etc.

5086 H111 aluminum is particularly suitable for shipbuilding, transportation, and other fields requiring corrosion resistance and weldability.

5086 H111 aluminum alloy is a “corrosion-resistant + easy-to-process” balanced material. Its core value lies in the fact that it does not require complex heat treatment to achieve moderate strength through cold working, while also offering excellent seawater and atmospheric corrosion resistance. Whether in marine engineering, transportation, or architectural decoration, whenever the demand focuses on “good formability, corrosion resistance, and lightweight, ” 5086 H111 is a highly cost-effective choice.

In addition, 5086 H111 aluminum is a well-balanced anti-rust alloy, especially suitable for applications requiring resistance to marine corrosion or large amounts of welding work.

What is H111 aluminium?

Generally, H111 aluminium is a temper designation indicating partially processed hardened material that provides good formability and medium strength for various manufacturing needs.

- Processing Method: Strain-hardened

- Hardness: Strength is below the allowable value of H11 (1/8 hardness)

"5086" represents the alloy composition system, and "H111" represents the temper (strain-hardened state), which is widely used in scenarios requiring both corrosion resistance and workability.

H111 temper: a low strain-hardened “easy formability” condition. Tempers starting with "H" belong to strain-hardened states (strengthened through cold working without subsequent heat treatment). H111 is one of the “low strain-hardened grades.”

It undergoes slight cold working (usually deformation <5%) without subsequent annealing or solution treatment. The purpose is to “fine-tune properties”: retain the ductility of 5086 alloy while slightly increasing strength (5%–10% higher compared with the O temper “fully annealed state”). Core advantages: excellent formability (easily bendable, stampable, rollable), no need for aging after processing, and suitable for manufacturing complex-shaped parts.

5086 h111 aluminum plate sheet specifications

| Alloy | 5086 |

| Temper | O, H111, H116, H321 |

| Thickness | 0.8-200mm |

| Width | 500-2800mm |

| Length | 1000mm-12000mm (Can be cut) |

| Normal dimension | 1250*2500mm, 1500mm*3000mm. |

| Standard | QQ-A-250/7 5086 sheet and plate |

| Aluminum plate price | Factory price |

5086 h111 aluminum corrosion resistance

- Excellent atmospheric corrosion resistance (can be used outdoors for long periods without coating, forming a dense oxide film on the surface);

- Outstanding marine corrosion resistance (resistant to seawater and salt spray corrosion, superior to most aluminum alloys);

- No risk of "stress corrosion cracking (SCC)" (since it does not contain copper, it avoids the SCC problems of 2000 series).

Characteristics of 5086 H111 Aluminum Plate Sheet

- Strength: 5086 H111 has medium strength. Compared with higher temper states such as H32, its strength is lower, but it is suitable for many general applications.

- Ductility: higher than harder temper states, making it easier to process.

- Formability: good, easier to process and form compared with harder temper states.

- Excellent corrosion resistance: it offers outstanding corrosion resistance, making it very suitable for seawater and other harsh environments.

- Good weldability: this alloy can be easily welded using various welding techniques.

- High formability: the H111 temper has good flexibility, making it easier to fabricate and bend.

| Property | Description |

| Strength | Lower, suitable for applications requiring high ductility |

| Weldability | Good, suitable for welding and joining operations |

| Ductility | High, exhibiting excellent plasticity and machinability |

| Yield Strength/Tensile Strength | Relatively low, but performs exceptionally well in applications requiring high plasticity |

Mechanical properties of 5086 h111 aluminum plates

| Temper | Room temperature test result | |||

| Tension strength/MPa | Yield strength/MPa | Elongation/% | Hardness | |

| O/H111 | 240-310 | 100 | 11-17 | 65 |

| H116/H321 | 275 | 195 | 8-10 | 81 |

| H22/H32 | 275-335 | 185 | 5-10 | 80 |

| H24/H34 | 300-360 | 220 | 4-8 | 88 |

| H26/H36 | 325-385 | 250 | 3 | 96 |

Chemical composition of 5086 aluminum sheets

| Chemical composition | |

| Al | REM |

| Si | ≤0.4 |

| Fe | ≤0.5 |

| Cu | ≤0.1 |

| Mn | 0.2-0.7 |

| Mg | 3.5-4.5 |

| Cr | 0.05-0.25 |

| Zn | ≤0.25 |

| Ti | ≤0.15 |

| Note: EACH≤0.05; TOTAL≤0.15 | |

5086 H111 Aluminum Sheet Plate Hot Selling Sizes

| Product | Width (In.) | Length (In.) |

| 0.063" Aluminum Sheet 5086-H111 | 30" | 96" |

| 0.063" Aluminum Sheet 5086-H111 | 30" | 120" |

| 0.063" Aluminum Sheet 5086-H111 | 30" | 144" |

| 0.063" Aluminum Sheet 5086-H111 | 36" | 96" |

| 0.063" Aluminum Sheet 5086-H111 | 36" | 120" |

| 0.063" Aluminum Sheet 5086-H111 | 36" | 144" |

| 0.063" Aluminum Sheet 5086-H111 | 48" | 96" |

| 0.063" Aluminum Sheet 5086-H111 | 48" | 120" |

| 0.063" Aluminum Sheet 5086-H111 | 48" | 144" |

| 0.08" Aluminum Sheet 5086-H111 | 30" | 96" |

| 0.08" Aluminum Sheet 5086-H111 | 30" | 120" |

| 0.08" Aluminum Sheet 5086-H111 | 30" | 144" |

| 0.08" Aluminum Sheet 5086-H111 | 36" | 96" |

| 0.08" Aluminum Sheet 5086-H111 | 36" | 120" |

| 0.08" Aluminum Sheet 5086-H111 | 36" | 144" |

| 0.08" Aluminum Sheet 5086-H111 | 48" | 96" |

| 0.08" Aluminum Sheet 5086-H111 | 48" | 120" |

| 0.08" Aluminum Sheet 5086-H111 | 48" | 144" |

| 0.09" Aluminum Sheet 5086-H111 | 30" | 96" |

| 0.09" Aluminum Sheet 5086-H111 | 30" | 120" |

| 0.09" Aluminum Sheet 5086-H111 | 30" | 144" |

| 0.09" Aluminum Sheet 5086-H111 | 36" | 96" |

| 0.09" Aluminum Sheet 5086-H111 | 36" | 120" |

| 0.09" Aluminum Sheet 5086-H111 | 36" | 144" |

| 0.09" Aluminum Sheet 5086-H111 | 48" | 96" |

| 0.09" Aluminum Sheet 5086-H111 | 48" | 120" |

| 0.09" Aluminum Sheet 5086-H111 | 48" | 144" |

| 1/8" Aluminum Sheet 5086-H111 | 30" | 96" |

| 1/8" Aluminum Sheet 5086-H111 | 30" | 120" |

| 1/8" Aluminum Sheet 5086-H111 | 30" | 144" |

| 1/8" Aluminum Sheet 5086-H111 | 36" | 96" |

| 1/8" Aluminum Sheet 5086-H111 | 36" | 120" |

| 1/8" Aluminum Sheet 5086-H111 | 36" | 144" |

| 1/8" Aluminum Sheet 5086-H111 | 48" | 96" |

| 1/8" Aluminum Sheet 5086-H111 | 48" | 120" |

| 1/8" Aluminum Sheet 5086-H111 | 48" | 144" |

| 0.160" 5086-H111 Aluminum Sheet | 30" | 96" |

| 0.160" 5086-H111 Aluminum Sheet | 30" | 120" |

| 0.160" 5086-H111 Aluminum Sheet | 30" | 144" |

| 0.160" 5086-H111 Aluminum Sheet | 36" | 96" |

| 0.160" 5086-H111 Aluminum Sheet | 36" | 120" |

| 0.160" 5086-H111 Aluminum Sheet | 36" | 144" |

| 0.160" 5086-H111 Aluminum Sheet | 48" | 96" |

| 0.160" 5086-H111 Aluminum Sheet | 48" | 120" |

| 0.160" 5086-H111 Aluminum Sheet | 48" | 144" |

| 0.188" 5086-H111 Aluminum Sheet | 30" | 96" |

| 0.188" 5086-H111 Aluminum Sheet | 30" | 120" |

| 0.188" 5086-H111 Aluminum Sheet | 30" | 144" |

| 0.188" 5086-H111 Aluminum Sheet | 36" | 96" |

| 0.188" 5086-H111 Aluminum Sheet | 36" | 120" |

| 0.188" 5086-H111 Aluminum Sheet | 36" | 144" |

| 0.188" 5086-H111 Aluminum Sheet | 48" | 96" |

| 0.188" 5086-H111 Aluminum Sheet | 48" | 120" |

| 0.188" 5086-H111 Aluminum Sheet | 48" | 144" |

| 0.190" 5086-H111 Aluminum Sheet | 30" | 96" |

| 0.190" 5086-H111 Aluminum Sheet | 30" | 120" |

| 0.190" 5086-H111 Aluminum Sheet | 30" | 144" |

| 0.190" 5086-H111 Aluminum Sheet | 36" | 96" |

| 0.190" 5086-H111 Aluminum Sheet | 36" | 120" |

| 0.190" 5086-H111 Aluminum Sheet | 36" | 144" |

| 0.190" 5086-H111 Aluminum Sheet | 48" | 96" |

| 0.190" 5086-H111 Aluminum Sheet | 48" | 120" |

| 0.190" 5086-H111 Aluminum Sheet | 48" | 144" |

| 0.249" 5086-H111 Aluminum Plate | 30" | 96" |

| 0.249" 5086-H111 Aluminum Plate | 30" | 120" |

| 0.249" 5086-H111 Aluminum Plate | 30" | 144" |

| 0.249" 5086-H111 Aluminum Plate | 36" | 96" |

| 0.249" 5086-H111 Aluminum Plate | 36" | 120" |

| 0.249" 5086-H111 Aluminum Plate | 36" | 144" |

| 0.249" 5086-H111 Aluminum Plate | 48" | 96" |

| 0.249" 5086-H111 Aluminum Plate | 48" | 120" |

| 0.249" 5086-H111 Aluminum Plate | 48" | 144" |

| 0.375" 5086-H111 Aluminum Plate | 30" | 96" |

| 0.375" 5086-H111 Aluminum Plate | 30" | 120" |

| 0.375" 5086-H111 Aluminum Plate | 30" | 144" |

| 0.375" 5086-H111 Aluminum Plate | 36" | 96" |

| 0.375" 5086-H111 Aluminum Plate | 36" | 120" |

| 0.375" 5086-H111 Aluminum Plate | 36" | 144" |

| 0.375" 5086-H111 Aluminum Plate | 48" | 96" |

| 0.375" 5086-H111 Aluminum Plate | 48" | 120" |

| 0.375" 5086-H111 Aluminum Plate | 48" | 144" |

| 3/16" Aluminum Sheet 5086-H111 | 30" | 96" |

| 3/16" Aluminum Sheet 5086-H111 | 30" | 120" |

| 3/16" Aluminum Sheet 5086-H111 | 30" | 144" |

| 3/16" Aluminum Sheet 5086-H111 | 36" | 96" |

| 3/16" Aluminum Sheet 5086-H111 | 36" | 120" |

| 3/16" Aluminum Sheet 5086-H111 | 36" | 144" |

| 3/16" Aluminum Sheet 5086-H111 | 48" | 96" |

| 3/16" Aluminum Sheet 5086-H111 | 48" | 120" |

| 3/16" Aluminum Sheet 5086-H111 | 48" | 144" |

| 3/4" Aluminum Plate 5086-H111 | 30" | 96" |

| 3/4" Aluminum Plate 5086-H111 | 30" | 120" |

| 3/4" Aluminum Plate 5086-H111 | 30" | 144" |

| 3/4" Aluminum Plate 5086-H111 | 36" | 96" |

| 3/4" Aluminum Plate 5086-H111 | 36" | 120" |

| 3/4" Aluminum Plate 5086-H111 | 36" | 144" |

| 3/4" Aluminum Plate 5086-H111 | 48" | 96" |

| 3/4" Aluminum Plate 5086-H111 | 48" | 120" |

| 3/4" Aluminum Plate 5086-H111 | 48" | 144" |

| 1/2" Aluminum Plate 5086-H111 | 30" | 96" |

| 1/2" Aluminum Plate 5086-H111 | 30" | 120" |

| 1/2" Aluminum Plate 5086-H111 | 30" | 144" |

| 1/2" Aluminum Plate 5086-H111 | 36" | 96" |

| 1/2" Aluminum Plate 5086-H111 | 36" | 120" |

| 1/2" Aluminum Plate 5086-H111 | 36" | 144" |

| 1/2" Aluminum Plate 5086-H111 | 48" | 96" |

| 1/2" Aluminum Plate 5086-H111 | 48" | 120" |

| 1/2" Aluminum Plate 5086-H111 | 48" | 144" |

| 1" Aluminum Plate 5086-H111 | 30" | 96" |

| 1" Aluminum Plate 5086-H111 | 30" | 120" |

| 1" Aluminum Plate 5086-H111 | 30" | 144" |

| 1" Aluminum Plate 5086-H111 | 36" | 96" |

| 1" Aluminum Plate 5086-H111 | 36" | 120" |

| 1" Aluminum Plate 5086-H111 | 36" | 144" |

| 1" Aluminum Plate 5086-H111 | 48" | 96" |

| 1" Aluminum Plate 5086-H111 | 48" | 120" |

| 1" Aluminum Plate 5086-H111 | 48" | 144" |

Applications of 5086 H111 Aluminum Plate Sheet

- Shipbuilding and Marine Engineering: used in hulls, decks, and offshore platform structures, in scenarios requiring high corrosion resistance and medium strength.

- Transportation: automotive sheets, weldable aircraft components, as well as missile parts, armor, and other military fields.

- Industrial Equipment: pressure vessels, refrigeration units, TV towers, and other equipment requiring fire and corrosion resistance.

Marine and Shipbuilding Engineering

- Applications: ship decks, side guard plates, bulkheads, offshore platform railings, seawater pipelines.

- Reasons: seawater corrosion resistance, good formability (can adapt to complex ship surfaces), lightweight (reduces ship fuel consumption).

Transportation Field

- Applications: body panels of RVs/campers, truck bed floors, luggage racks; fuel tanks and guardrails for light trucks.

- Reasons: strong outdoor corrosion resistance, can be cold-formed into complex shapes, lightweight (improves vehicle range).

Pressure Vessels and Storage Tanks

- Applications: small oil tanks, chemical storage tanks (for non-strongly corrosive liquids), LPG cylinder covers.

- Reasons: good plasticity (can be stamped into pressure vessel shapes), strong corrosion resistance (prevents tank inner wall corrosion).

Architecture and Decoration

- Applications: auxiliary frames for outdoor curtain walls, skeletons of sunshades, non-load-bearing frames of aluminum alloy doors and windows.

- Reasons: atmospheric corrosion resistance (no need for frequent maintenance), easy processing (can be bent into decorative shapes).

Other Fields

- Medical equipment: wheelchair frames, rehabilitation equipment parts (require lightweight and sweat corrosion resistance).

- Electronic equipment: enclosures for large equipment (such as server cabinets, industrial control boxes, requiring heat dissipation and corrosion resistance).

Comparison of 5086 H111 Aluminum with Other Tempers

- Compared to H112 temper: 5086 aluminum in H111 temper has better ductility than H112 temper but slightly lower strength.

- Compared to other variants: Among the different tempers of 5086 aluminum, H111 state has higher plasticity but lower strength compared to some harder tempers.

5086 h111 aluminum Selection Considerations

Differences from other tempers:

- If higher strength is required: choose 5086 H32 (strain-hardened + stabilized, but slightly poorer formability);

- If ultimate formability is required: choose 5086 O temper (fully annealed, but with the lowest strength).

Welding considerations:

- Use 5183 welding wire (aluminum-magnesium alloy wire matching 5086) during welding, avoid using pure aluminum wire (which leads to insufficient weld strength).

- For thick plates (>6mm), preheating (100~150℃) is required before welding to prevent weld cracking.

Surface treatment options:

- For marine environments, hard anodizing is recommended (oxide film thickness 10~20μm, improves corrosion resistance).

- For architectural decoration, fluorocarbon spraying is recommended (weather resistance of more than 20 years, color options available).

Avoid high-temperature use:

Long-term service temperature should not exceed 120℃ (exceeding this will cause strength reduction and magnesium precipitation), not suitable for high-temperature environments such as engine compartments.

Haomei 5086 H32 Aluminum Alloy Products

5086 H111 Sheet

5086 H111 aluminum sheet is a cold-rolled or hot-rolled flat product with excellent corrosion resistance, medium strength, and good formability. It is widely used in marine applications, transportation, and industrial equipment where lightweight and weldable materials are required.

- Applications: ship decks, automotive panels, pressure vessels, architectural cladding.

- Characteristics: easy to bend and cut, high ductility, good surface finish.

- Advantages: excellent corrosion resistance in seawater and atmospheric environments, suitable for welding.

5086 H111 Plate

5086 H111 aluminum plate is a thicker flat product, offering the same corrosion resistance and moderate strength as the sheet, but suitable for structural and load-bearing applications. Its formability and weldability make it ideal for heavy-duty marine and industrial structures.

- Applications: ship hulls, offshore platforms, pressure vessel walls, structural panels.

- Characteristics: can be machined, rolled, or welded into complex structures.

- Advantages: high corrosion resistance, lightweight yet strong enough for structural components.

5086 H111 Round Bar

5086 H111 round bar is a solid cylindrical product made from aluminum-magnesium alloy, known for its corrosion resistance and moderate strength. It is commonly used in mechanical and marine engineering applications where lightweight and anti-corrosion performance are critical.

- Applications: shafts, fasteners, marine fittings, machinery components.

- Characteristics: can be machined, turned, or drilled, good tensile strength and elongation.

- Advantages: lightweight, resistant to seawater corrosion, easy to fabricate for precise components.

5086 H111 Tube

5086 H111 aluminum tube is a hollow cylindrical product with excellent corrosion resistance and moderate strength. It is used in fluid transport, structural frameworks, and marine or automotive applications where lightweight and corrosion-resistant tubing is required.

- Applications: piping systems, handrails, scaffolding, marine tubing, automotive tubing.

- Characteristics: lightweight, can be bent or welded, maintains dimensional stability under load.

- Advantages: excellent corrosion resistance in marine and industrial environments, easy to handle and fabricate.

Products you may be interested in