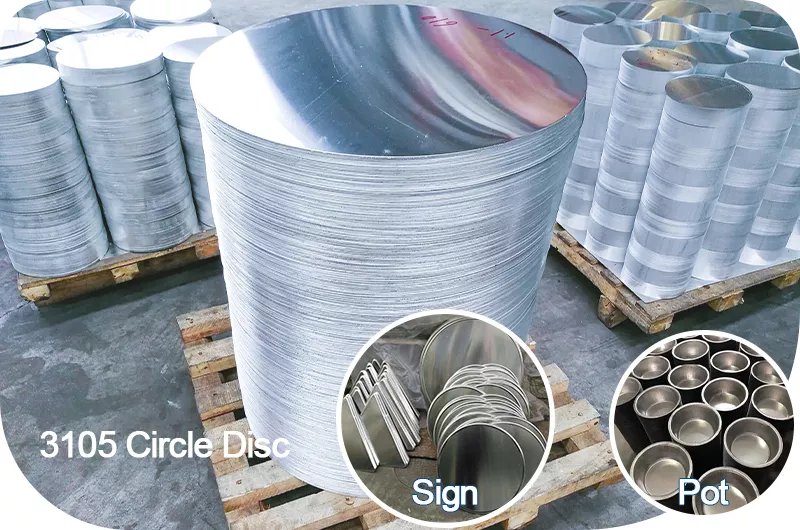

3105 Aluminum Circle Disc

3105 aluminum circle disc refers to circular sheet material made from 3105 aluminum alloy. Essentially, it is a processed form of 3105 aluminum alloy plate, belonging to the 3000 series aluminum alloy family.

The 3105 aluminum circle disc is a versatile aluminum alloy product that combines lightweight, corrosion resistance, and good machinability, making it especially suitable for applications requiring medium strength and excellent formability. As a non-heat-treatable alloy, it achieves different strength levels through cold working, meeting the needs of various fields ranging from packaging to construction and electronics, making it an indispensable metal material in modern industry.

The 3105 aluminum circle disc refers to pre-cut circular discs or blanks made from 3105 aluminum alloy. This alloy is known for its excellent formability, deep-drawing capability, and corrosion resistance, making it ideal for cookware (pots, pans), lighting reflectors, bottle caps, wall panels, and general sheet metal processing where slightly higher strength than 3003 alloy is required but heat treatment is unnecessary.

3105 Aluminum Circle Disc Specifications

| Specification | Typical Range |

| Alloy & Temper | 3105 (O, H12, H14, H18, H24) |

| Thickness | 0.3mm – 10.0mm (0.012" – 0.4") |

| Diameter | 15mm – 1500mm (0.6" – 60") |

| Standards | ASTM B209, EN 485, GB/T 3880 |

| Common Thickness | 0.3mm – 6.0mm (commonly 1.0mm-3.0mm for cookware; 0.2mm-0.5mm for bottle caps) |

| Common Diameter | 100-500mm most common (for pots); road signs usually 600-900mm. |

| Diameter Tolerance | ±0.5mm to ±2.0mm depending on cutting method (stamping or shearing) |

| Surface Treatment | Mill finish, customizable coating (substrate for non-stick coating) or anodizing. |

3105 Aluminum Circle Disc Common Tempers

O (Fully Annealed):

- Features: Softest, highest elongation, internal stress fully relieved.

- Applications: Specifically for deep drawing and spinning, e.g., deep soup pots, shaped vessels, complex lampshades. If you need to stretch the disc very deep, O temper is required.

H14 / H24 (Half Hard):

- Features: Semi-hard, has certain hardness while retaining good bending performance.

- Applications: Conventional cookware (like frying pans), traffic signs, billboards. Ensures products are not easily deformed in use.

H16 / H18 / H19 (Harder):

- Features: High hardness, high strength, but almost no elongation.

- Applications: Mainly used for bottle cap materials, electronic gaskets, or flat decorative parts.

3105 Aluminum Circle Disc Features and Performance

3105 is an aluminum-manganese alloy with an aluminum content of about 98%. Due to the addition of small amounts of magnesium and manganese, its strength is slightly higher than 1100 or 3003 alloys.

Features

- Excellent formability and deep-drawing performance, ideal for processing cookware and similar products.

- Non-heat-treatable: Strength is achieved through cold working (strain hardening) rather than heat treatment.

- Corrosion resistance: Excellent resistance to atmospheric and seawater corrosion.

- Formability: Extremely good ductility, suitable for deep drawing, spinning, and bending, not prone to cracking.

- Weldability: Can be easily welded using standard methods like TIG or MIG.

- Surface treatment: Usually provided as "mill finish, " but also suitable for anodizing or painting (commonly used for sign production).

Performance Advantages

| Characteristic | Performance | Advantages |

| Machinability | Excellent | Suitable for deep drawing, spinning, bending, and welding, not prone to cracking. |

| Corrosion Resistance | Outstanding | Performs stably in humid, greasy environments (e.g., kitchens), does not rust. |

| Surface Quality | Smooth and flat | Suitable for coating, anodizing, sandblasting, and other secondary processing. |

| Strength | Medium-high | Stronger than 1050/1100 pure aluminum, capable of withstanding certain gas pressures (e.g., bottle caps). |

Chemical composition of 3105 Aluminium Circle

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| Content (max) | 0.6 | 0.7 | 0.3 | 0.3.-0.80 | 0.20-0.80 | 0.2 | 0.4 | 0.1 | 0.15 | remain |

Mechenical Property of 3105 Aluminum Circle

| Alloy Temper | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 3105 0 | >0.2-0.5 | 75-105 | ≥25 | ≥14 | 32-42 |

| >0.5-1.0 | ≥20 | ||||

| >1.0-4.0 | ≥25 | ||||

| 3105 H22 | >0.2-0.5 | 95-130 | ≥75 | ≥10 | 39-60 |

| >0.5-1.0 | ≥12 | ||||

| >1.0-4.0 | ≥12 | ||||

| 3105 H24 | >0.2-0.5 | 110-145 | ≥95 | ≥8 | 52-62 |

| >0.5-1.0 | ≥10 | ||||

| >1.0-4.0 | ≥10 | ||||

| 3105 H26 | >0.2-0.5 | 130-165 | ≥115 | ≥3 | 58-72 |

| >0.5-1.0 | ≥4 | ||||

| >1.0-4.0 | ≥6 | ||||

| 3105 H18 | >0.2-0.5 | ≥150 | ≥130 | ≥2 | 65-95 |

| >0.5-1.0 | ≥2 | ||||

| >1.0-4.0 | ≥3 |

Applications of 3105 Aluminum Discs

- For high-end non-stick cookware manufacturing, it is generally recommended to choose 3105 aluminum discs in the O temper (annealed state), as it is the softest and offers the best deep drawing performance.

- For traffic signs, you can select harder tempers such as H14 or H24 to ensure the signs are less prone to deformation.

Cookware and Kitchenware

Due to its excellent deep drawing and spinning performance, 3105 aluminum discs are widely used in the production of various cookware.

- Non-stick and pressure cookers: Good thermal conductivity and formability make it an ideal material for pot bottoms and bodies.

- Deep-drawn vessels: Such as soup pots, rice bowls, and other cookware that require multiple stretching operations.

- Kitchen hardware: Kettles, inner pots of rice cookers, etc.

Lighting and Lamp Industry

Due to aluminum's good reflectivity and heat dissipation, 3105 aluminum discs are often used to manufacture:

- Lampshades: Processed into various shapes of industrial and mining lamps or table lamps using spinning techniques.

- Reflectors: After anodizing or polishing, used as reflective components in indoor and outdoor lighting equipment.

Traffic and Architectural Decoration

- Traffic signs: 3105 alloy has excellent weather resistance and corrosion resistance, making it very suitable for road signs and circular traffic signs.

- Bottle caps and packaging: With slightly higher strength than 3003 and good ease of opening, it is commonly used for beverage, pharmaceutical, or cosmetic screw caps.

- Architectural exterior fittings: Such as drain covers, rainwater funnels, and some decorative aluminum discs.

Electrical and Industrial Applications

- Capacitor housings: 3105 aluminum discs can be stretched to serve as protective covers for electronic components.

- Pressure vessel caps: Used as end caps for certain low-pressure vessels.

- Manufacturing non-stick/pressure cookers: Recommended 3105-O temper, thickness 2.0-4.5mm.

- Manufacturing road signs: Recommended 3105-H24, thickness 1.5-2.5mm, high hardness to resist wind deformation.

- Manufacturing bottle caps/screw caps: Recommended 3105-H14 or H16, thickness 0.2-0.3mm.

- Manufacturing ordinary lampshades: Recommended 3105-O temper, suitable for spinning forming.

3105 Aluminum Disc Processing Methods

The processing methods of 3105 aluminum discs are mainly divided into Direct Chill (DC) casting and Continuous Casting (CC). The core difference between the two lies in the crystallization speed and heat treatment process, which directly affects the performance of the aluminum discs in subsequent deep drawing or spinning.

- Direct Chill (DC): Recommended for cookware and products requiring deep drawing or spinning, due to its superior surface quality and ductility.

- Continuous Casting (CC): More cost-effective for traffic signs and simple caps with flat applications.

3105 DC Hot Rolled Aluminum Circle / Disc

Surface quality: Excellent oxidation effect. After anodizing, the surface has a uniform color without streaks, making it the preferred choice for high-end non-stick and pressure cookware.

Recommended applications:

- High deep-drawn parts: Soup pots or rice cooker inner pots with depths exceeding 1.5 times the diameter.

- Spun parts: Lampshades or industrial containers requiring extremely high ductility.

3105 CC Cast Rolled Aluminum Circle / Disc

Cost advantage: Shorter production process, lower energy consumption, no expensive hot rolling process, usually 15-20% cheaper than DC material.

Recommended applications:

- Flat applications: Traffic signs, billboards. These products only require simple cutting or light bending.

- Shallow-drawn parts: Bottle caps, shallow trays, electronic gaskets.

3105 DC CC Aluminum Circle / Disc Comparison Table

| Property | Direct Chill (DC / Hot Rolled) | Continuous Casting (CC / Cast Rolled) |

| Microstructure | Uniform equiaxed grains, fine structure | Fibrous structure, strong directionality |

| Elongation | Very high (usually > 30%) | General (usually 15%-20%) |

| Deep drawing ratio | Supports multiple deep drawing passes | Limited to shallow drawing or flat applications |

| Oxidation effect | Mirror or uniform matte, no color difference | Prone to black lines or color blocks |

| Production cost | Higher (complex process) | Lower (efficient) |

| Main applications | High-end cookware, pressure cookers, deep lampshades | Traffic signs, bottle caps, general decorations |

Recommendations

- For "pots": Regardless of the depth of drawing, if stamping deformation is involved, DC hot rolled material is the only reliable choice, which significantly reduces scrap rate and ensures coating adhesion (e.g., Teflon).

- For "signs": CC cast-rolled material fully meets strength requirements and can greatly reduce procurement costs.

3105 Aluminum Disc Selection Guide

Choose the appropriate temper according to application:

- Deep drawing/stretching applications: O temper (high ductility)

- Structural support parts: H14~H18 (medium strength + moderate ductility)

- High hardness required: H26~H28 (high strength + low ductility)

- Bottle caps, pressure vessels: H19 (very high strength)

Further reading

- 3105 Aluminum Plate Sheet

- 3105 h14 aluminum sheet plate

- 3105 h24 aluminum sheet plate

- 3105 painted aluminum sheet

- 3105 Aluminum Coil

- 3105 Aluminum Strip

Users viewing this material also viewed the following

- 3105 Coated Aluminum Coils

- 3105 Aluminum for Wine Bottle Caps

- 3105 Aluminum Coil for Venetian Blinds

- 3105 Aluminum for Beverage Cans

- 3105 Aluminum for Roofing Panels

- 3105 Corrugated Aluminum Sheet

- 3105 Aluminum for Lamp Holders

- 3105 Aluminum for Bottle Caps

Recommended Content