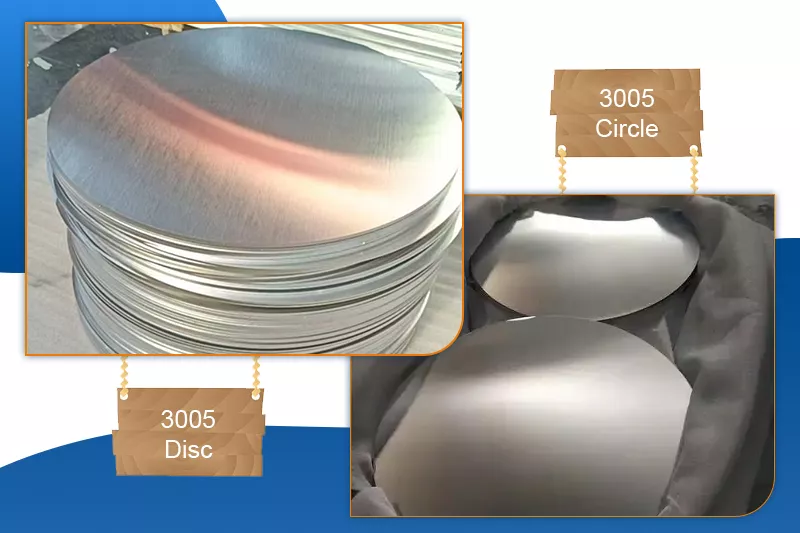

3005 Aluminum Circle Disc

3005 aluminum circle discs are circular sheets made from 3005 aluminum alloy. They belong to the 3000 series (aluminum–manganese) rust-resistant aluminum alloys and are commonly used as raw materials for further forming or manufacturing processes.

3005 aluminum circle discs combine corrosion resistance, good machinability, excellent deep drawing performance, weldability, and moderate strength. They are widely used in cookware, construction, electronics, automotive, and other industries.

Compared with 3003, 3005 aluminum circle discs offer approximately 20% higher strength and better corrosion resistance. Compared with 5052, they are more cost-effective and provide better formability. When selecting, choosing the appropriate temper and specifications based on specific application requirements for strength, corrosion resistance, and formability can achieve the best cost performance.

3005 aluminum circle discs (or circles) are specialized semi-finished products. They are ideal raw materials for deep-drawn products such as non-stick cookware, pressure cookers, and lamp shades, because the 3005 alloy is less prone to cracking during the drawing process.

3005 Aluminum Circle Disc Specifications

| Item | Specification |

| Alloy | 3005 Aluminum |

| Diameter | 20 – 2300 mm |

| Thickness | 0.02 – 200 mm Common range: 0.2 – 6 mm |

| Temper | O (Annealed), H14 (1/4 Hard), H24 (1/2 Hard), H18 (Full Hard) Other tempers available upon request |

| Surface Finish | Mill Finish, Polished, Brushed, Mirror, Sandblasted, Anodized, Embossed, etc. |

| Processing Method | Precision Cutting / Punching / Blanking |

| Custom Service | Custom diameter, thickness, temper, and surface finish available |

Performance Comparison of Different Tempers (O / H14 / H24) for 3005 Aluminum Circle Disc

| Temper | Characteristics | Typical Applications |

| O Temper (Annealed) | Lowest strength, highest ductility, elongation ≥ 20%, easy for deep drawing and bending | Products requiring complex forming, such as rice cooker inner pots |

| H14 Temper | Medium strength, good formability, excellent surface quality | Lamp shades, decorative trays, shallow-drawn parts |

| H24 Temper | Higher strength, moderate hardness, strong resistance to deformation | Architectural decoration, automotive components, load-bearing structures |

3005 Aluminum Circle Disc Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Others | Al |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.2-0.6 | 0.1 | - | 0.25 | 0.1 | 0.2 | Remainder |

Mechenical Property of 3005 Aluminium Circle Disc

| Alloy Temper | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 3005 O | >0.2-0.5 | 115-165 | ≥45 | ≥13 | 35-45 |

| >0.5-1.0 | ≥20 | ||||

| >1.0-4.0 | ≥25 | ||||

| 3005 H22 | >0.2-0.5 | 145-195 | ≥110 | ≥10 | 40-60 |

| >0.5-1.0 | ≥15 | ||||

| >1.0-4.0 | ≥15 | ||||

| 3005 H24 | >0.2-0.5 | 170-215 | ≥130 | ≥6 | 58-70 |

| >0.5-1.0 | ≥8 | ||||

| >1.0-4.0 | ≥10 | ||||

| 3005 H26 | >0.2-0.5 | 195-240 | ≥160 | ≥3 | 65-83 |

| >0.5-1.0 | ≥4 | ||||

| >1.0-4.0 | ≥6 | ||||

| 3005 H18 | >0.2-0.5 | ≥220 | ≥200 | ≥2 | 80-100 |

| >0.5-1.0 | ≥3 | ||||

| >1.0-4.0 | ≥3 |

3005 Aluminum Circle Disc Characteristics

- Formability: Excellent deep drawing, spinning, and forming performance, allowing processing into complex shapes.

- Corrosion Resistance: Good resistance to moisture, ultraviolet exposure, and general corrosion, making it an ideal choice for outdoor and kitchen applications.

- Thermal Performance: High thermal conductivity, suitable for heat dissipation applications.

- Surface: Can be surface treated to achieve high hardness and scratch resistance while maintaining its natural metallic luster.

- Higher Strength than 3003 Alloy: Approximately 20% higher strength than 3003 alloy while maintaining good workability.

- Excellent Formability and Weldability: Can be deep drawn, stretched, or welded using common methods.

- Available Tempers: O (annealed), H12, H14, H16, H18, H22, H24, etc., depending on the required hardness and formability.

3005 Aluminum Circle Disc Applications

Due to its balanced performance, 3005 aluminum circle discs are widely used across multiple industries:

- Building Materials: Commonly used for color-coated aluminum sheets, curtain walls, louvers, roofing, and other decorative or structural components.

- Household Cookware: A commonly used material for manufacturing various pots, pans, and kitchen utensils.

- Electronics and Daily Products: Used for producing heat sinks, cosmetic covers, lamp components, and more.

- Containers and Chemical Industry: Suitable for manufacturing tanks, containers, and chemical equipment components that require corrosion resistance and weldability.

- Lighting and Decoration: Lamp shades, reflectors, decorative panels.

- Transportation: Automotive components and traffic signs.

Cookware Industry

- Rice cooker inner pots, cookware bottom heating plates

- Advantages: Fast and uniform heat conduction, resistance to acidic and alkaline food corrosion, lightweight

Architecture and Decoration

- Ceilings, curtain walls, louvers, decorative panels, curved components

- Advantages: Good weather resistance; can be anodized or painted to achieve various colors

Electronics and Electrical Appliances

- Heat sinks, heat exchangers, electronic equipment housings, lamp cap materials

- Advantages: Good thermal and electrical conductivity, electromagnetic shielding, lightweight

Automotive Industry

- Body panels (weight reduction up to 30%), roof racks, air-conditioning condensers, radiators

- Advantages: Lightweight design improves fuel efficiency, excellent corrosion resistance

Other Fields

- Solar reflectors, lighting equipment

- Marine interiors, chemical equipment

- Food packaging (compliant with food safety standards)

Advantages of 3005 Aluminum Circle Disc

- Outstanding deep drawing performance: Its fine grain structure makes it highly suitable for deep drawing processes (such as manufacturing deep pots or rice cooker inner liners) without surface defects like “orange peel.”

- Enhanced strength: The addition of magnesium provides better structural integrity than 1000 series or 3003 aluminum alloys.

- Corrosion resistance: Performs excellently in humid environments, making it an ideal material for kitchenware and automotive components.

- Surface finish: Features high reflectivity and responds well to anodizing, which is critical for non-stick coatings or decorative surface treatments.

Comparison of 3005 Aluminum Circle Disc with Other Alloys

3005 vs 3003

| Parameter | 3005 | 3003 | Difference |

| Manganese Content | 1.0~1.5% | 1.0% (min) | Higher Mn content in 3005 |

| Tensile Strength | 120~205MPa | 110~130MPa | About 20% higher for 3005 |

| Corrosion Resistance | Excellent | Good | 3005 is slightly better |

| Application Focus | Cookware and construction requiring higher strength | General cookware and common decoration | 3005 has a wider application range |

3005 vs 5052 (Representative of 5xxx Series)

| Parameter | 3005 | 5052 | Difference |

| Alloy Series | Al-Mn Series | Al-Mg Series | Different base alloying elements |

| Tensile Strength | 120~205MPa | 230MPa (H32 temper) | 5052 has higher strength |

| Seawater Corrosion Resistance | Good | Excellent | 5052 is more suitable for marine environments |

| Price | Moderate | Higher | 5052 has higher cost |

| Typical Applications | General anti-rust use, construction, cookware | Marine vessels, pressure vessels, high-strength structures | 5052 is suitable for more demanding conditions |

Production Process of 3005 Aluminum Circle Disc

Melting: High-purity aluminum ingots + alloying elements (such as manganese) are melted at 700–750°C, followed by refining and impurity removal.

Casting: Cast into slabs (approximately 65mm thick).

Homogenization treatment: Eliminates casting stress and improves microstructure.

Hot rolling: Heated to 500–700°C and rolled to a thickness of 8–12mm.

Cold rolling: Further reduced (to 0.2–6mm) to improve surface quality and strength.

Annealing: Softening treatment; different annealing temperatures are selected according to requirements.

Blanking: Stamped into circular shapes using molds.

Surface treatment (optional):

Anodizing: Improves corrosion resistance and decorative appearance.

Painting / Powder coating: Achieves various colors.

Polishing / Brushing: Enhances surface texture.

Tips for Choosing 3005 Aluminum Circle Disc

Key considerations when selecting 3005 aluminum circle discs:

- Strength requirements: Choose 3005 for moderate strength with good formability; consider 5052 if higher strength is required.

- Corrosive environment: 3005 is sufficient for general environments; 5052 is preferred for marine or high-salinity environments.

- Forming complexity: Choose O temper for deep drawing and complex bending; choose H14/H24 for simple forming or rigidity requirements.

- Cost budget: Choose 3003 for limited budgets, 3005 for better performance, and 5052 for high-end applications.

When ordering 3005 aluminum circle discs, the following parameters usually need to be specified:

- Temper: O temper is best for deep drawing; H14 or H24 tempers are more suitable for flat or lightly formed parts.

- Thickness: Typically ranges from 0.3mm to 6.0mm.

- Diameter: Depending on the supplier, diameters can range from 100mm to 1200mm.

In short, if you need a circular aluminum alloy sheet with better strength than pure aluminum, good corrosion resistance, and excellent formability for cookware, architectural decorative parts, or general industrial components, 3005 aluminum circle discs are a reliable and widely used choice.

Further reading

Users viewing this material also viewed the following

- 3005 Aluminum Disc for Cookware

- 3005 Pre-painted Aluminum Coil

- 3005 Aluminum Plate for Battery Shell

- 3005 Aluminum Coil Strip for Blinds

- 3005 Aluminum Plate for Curtain Walls

Recommended Content