Basic Introduction to Honeycomb Aluminum Foil

Definition of Honeycomb Aluminum Foil

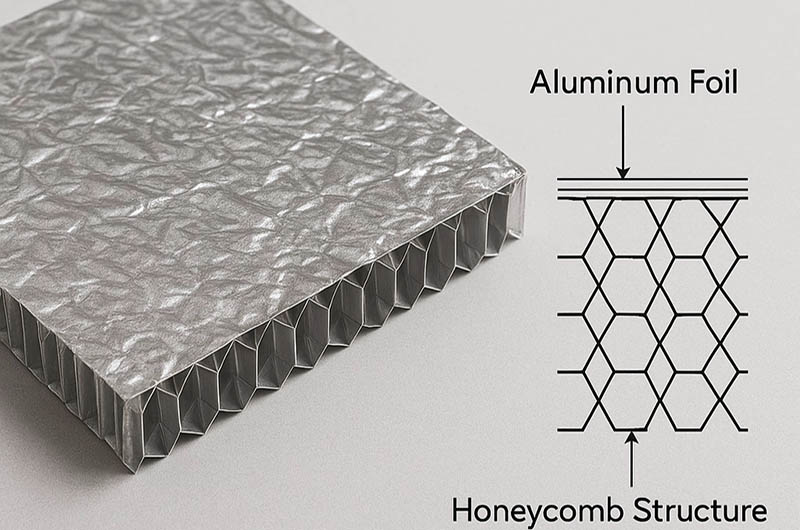

Honeycomb aluminum foil is the core raw material used to manufacture aluminum honeycomb cores, primarily serving as internal filling in honeycomb panels. It is a specialized material designed for applications requiring a high strength-to-weight ratio, thermal insulation performance, and structural stability. It is formed by bonding multiple layers of aluminum foil into a hexagonal honeycomb structure, then expanded to create a lightweight yet strong core material.

Raw Materials of Honeycomb Aluminum Foil

| Material Type | Item | Description |

| Aluminum Foil | Alloy | Commonly uses 3003, 5052 aluminum alloys, featuring rust resistance, high strength, and good workability. |

| Thickness | 0.03~0.1mm, classified as ultra-thin material, capable of bending and forming. | |

| Surface Treatment | Some products require anodizing or coating treatment to enhance corrosion resistance. | |

| Adhesive | Type | Epoxy resin, phenolic resin, or polyurethane adhesive, requiring high temperature resistance and strong bonding strength. |

| Function | Bonds aluminum foil into hexagonal honeycomb structure, providing excellent support after curing. | |

| Face Panel (Optional) | Material | Aluminum panel, composite panel, or plastic panel, etc. |

| Bonding Method | Uses hot-press bonding with adhesive film to combine top and bottom panels with the honeycomb core, forming a honeycomb panel structure. |

Principles of Honeycomb Aluminum Foil

| Category | Item | Description |

| Structural Design | Geometric Structure | Aluminum foil is bonded into continuous hexagonal honeycomb cells, similar to natural honeycomb, forming a dense array perpendicular to the panels. |

| Cell Size | Typically 2–20mm; smaller cells result in higher structural strength but also increased weight. | |

| Mechanical Principles | Load Distribution | Vertical pressure is converted into axial stress by the honeycomb walls, avoiding local collapse or deformation. The principle is similar to corrugated cardboard. |

| High Specific Strength | The hollow honeycomb structure reduces overall density to 0.1~0.5 g/cm³ (only about 1/10 of pure aluminum) while improving compressive and bending strength. | |

| Stability | Thin-walled honeycomb structure enhances buckling resistance, and the hexagonal geometry provides isotropic support. | |

| Functional Advantages | Thermal and Acoustic Insulation | Closed cells in the honeycomb core effectively block air convection, reducing the transmission of heat and sound waves. |

| Impact Resistance | The structure has energy absorption capacity, cushioning external impacts, and is widely used in protective applications like automotive crash beams. | |

| Large Surface Stiffness | The "sandwich structure" (honeycomb core + upper and lower panels) improves bending stiffness, achieving both weight reduction and rigidity enhancement. |

Composition and Materials of Honeycomb Aluminum Foil

Structure of Honeycomb Aluminum Foil

Honeycomb aluminum foil is formed by bonding multiple layers of aluminum foil and expanding them into a hexagonal honeycomb structure, similar to natural beehives. This geometric structure achieves excellent strength with minimal material consumption:

- Hexagonal Structure: Maximizes load distribution and structural stability while minimizing weight.

- Core Panel-Face Panel Assembly: Sandwiched between rigid outer layers (such as aluminum plates, stone, or composite materials) to form a sandwich panel with resistance to bending and deformation.

- Adjustable Unit Parameters: Cell size (side length 5–12 mm), aluminum foil thickness (0.018–0.2 mm), and core depth can be customized to meet specific strength/weight requirements.

Through bonding multiple layers of aluminum foil and expanding them after lamination, a regular hexagonal honeycomb grid is formed, commonly with side lengths of 5~12mm (e.g., 5mm, 6mm, 8mm). This densely packed structure resembles "mini I-beams" and distributes panel pressure while maintaining high flatness.

Material Composition of Honeycomb Aluminum

Made from aluminum alloy, mainly in 3003-H24/H18 or 3004-H18/H19 tempers (high-strength aluminum alloys), with thicknesses ranging from 0.03~0.08mm (typically 0.04~0.06mm). Among them, 3004 alloy is ideal due to its high strength and good formability without deformation.

Materials of Honeycomb Aluminum Face and Bottom Panels

| Part | Material Type | Features and Description |

| Face Panel | Aluminum Alloy Sheet (e.g., 3003, 5052) | Lightweight, rust-resistant, high strength, the main load-bearing component of the honeycomb panel structure. Thickness generally ranges from 0.5~1.5mm. |

| Stainless Steel Sheet | Excellent corrosion resistance, used for special requirements (e.g., marine, curtain walls), though heavier. | |

| Fiberglass Reinforced Plastic Panel (FRP) | Lightweight and weather-resistant, suitable for building facades, vehicle interiors, and similar applications. | |

| Stone Veneer Composite Panel | Used for high-end decoration; bonded with the honeycomb structure to reduce weight while maintaining aesthetics. | |

| Bottom Panel | Aluminum Alloy Sheet (same as face panel) | Symmetrical structure enhances flatness and overall strength. |

| PVC, PP Plastic Sheet | Used in cost-sensitive or lightweight-required scenarios. |

Thickness and Cell Size of Honeycomb Aluminum Foil

| Item | Parameter Range | Description |

| Aluminum Foil Thickness | 0.03~0.1 mm | Common thicknesses include 0.04mm, 0.05mm, 0.06mm. Thicker foil offers higher strength but increases weight. |

| Aluminum Foil Alloy | 3003, 5052, etc. | Provides rust resistance, good workability, and shear strength. |

| Cell Side Length | 2 ~ 20 mm | Common side lengths include 3mm, 6mm, 9mm, 12mm. Smaller side lengths provide higher strength but increase weight and cost. |

| Cell Shape | Regular Hexagon (Standard) | Optimal isotropic structure with uniform stress distribution and high stability. |

Honeycomb Aluminum Materials and Specifications

| Property | Details |

| Alloys | 3003, 3004 (H18/H19 temper), 5052; optimized for corrosion resistance/formability. |

| Cell Size | 1/8 inch – 1/2 inch |

| Density | Approximately 30–130 kg/m³ |

| Compressive Strength | Varies with cell size and foil type |

| Shear Strength | Varies with cell size and foil type |

| Operating Temperature | Up to 660°C |

| Foil Dimensions | Thickness: 0.018–0.2 mm; Width: 20–2, 300 mm. |

| Key Attributes | High surface cleanliness, dimensional accuracy, and elongation. |

Honeycomb Core Characteristics

Features and Performance

- High strength-to-weight ratio: The hexagonal geometry provides excellent rigidity while remaining lightweight, making it ideal for structural applications. It is five times lighter than solid aluminum with comparable stiffness.

- Thermal and acoustic insulation: The sealed air pockets reduce heat transfer (melting point: 660°C) and absorb sound waves (sound absorption coefficient: 0.9).

- Energy absorption: Predictably compresses under impact (e.g., up to 30% of its length), thereby protecting vehicle structures.

- Environmental resistance: Fireproof, moisture/mildew resistant, and fully recyclable.

- Corrosion resistance: Aluminum's natural oxide layer provides corrosion resistance, enhancing durability.

- Fire resistance: High melting point (~660°C) and non-flammable honeycomb structure make it suitable for fire-resistant applications.

- Environmental friendliness: Made from recyclable aluminum, non-toxic, and environmentally sustainable.

Performance Characteristics of Honeycomb Aluminum Foil

High strength, high-temperature resistance, corrosion resistance; lightweight, low density; excellent impact resistance and vibration damping; superior fire resistance.

Applications of Honeycomb Aluminum Foil

- Architectural Decoration: Curtain wall panels, ceilings, partition walls (replacing solid aluminum panels/composite panels)

- Transportation: High-speed rail/subway carriages, ship interiors, automotive crash energy absorption structures

- Industrial Equipment: Cleanroom panels, solar panel backplanes, printing table panels

- Home Appliances and Furniture: High-end furniture countertops, air conditioner filters, lighting panels

- Special Fields: Aerospace components (lightweight requirements), refrigerated vehicle insulation layers

- Aerospace: Due to its lightweight and high strength, it can be used for aircraft floors, doors, and partitions.

Applications of Honeycomb Aluminum Foil in Civil Architecture

Honeycomb aluminum foil is widely used in curtain wall exteriors and interior walls, ceiling systems due to its lightweight, high strength, and excellent thermal and acoustic insulation properties.

Its honeycomb structure effectively blocks heat conduction, reducing building energy consumption. Additionally, the aluminum foil surface can undergo various coatings or film treatments to meet different decorative styles and fire protection requirements, making it widely applicable in high-rise buildings, public spaces, and commercial complexes for both exterior facades and interior decoration.

Honeycomb Aluminum Foil as an Ideal Material for Vehicle and Ship Decoration

In the interiors and exteriors of automobiles, trains, and yachts, honeycomb aluminum foil is an ideal material choice due to its excellent shock resistance, corrosion resistance, and flame retardant properties.

Its honeycomb core layer provides stable support, enabling thin panels with high strength. The aluminum foil surface can be printed, coated, or laminated to meet the aesthetic and practical needs of luxury cabins, dashboards, door panels, floors, or ship cabin walls, while also reducing the overall weight of the vehicle or ship and improving energy efficiency.

Applications of Honeycomb Aluminum Foil in Aerospace

Honeycomb aluminum foil is extensively used in aircraft cabin partitions, floor panels, luggage rack liners, and fuselage interior panels, primarily due to its excellent strength-to-weight ratio and flame retardant properties.

The honeycomb structure can withstand significant shear and bending loads and has good impact resistance and energy absorption capabilities, meeting the stringent material requirements of aircraft and spacecraft in extreme environments, while effectively reducing fuel consumption and enhancing passenger comfort.

What Other Industries Use It?

Honeycomb aluminum foil is also widely used in the insulation layers of refrigeration equipment and thermal insulation boxes, support panels for solar photovoltaic modules, industrial cleanroom wall panels, as well as lightweight framework materials in exhibition halls and stage construction.

Additionally, in furniture manufacturing, advertising signage, fire partitions, and high-speed train carriage partitions, the lightweight, high strength, corrosion resistance, and plasticity advantages of honeycomb aluminum foil are utilized to achieve designs that are both aesthetically pleasing and practical.

Selection and Maintenance of Honeycomb Aluminum Foil

How to Choose the Appropriate Thickness of Honeycomb Aluminum Foil?

When selecting the thickness of honeycomb aluminum foil, it is essential to determine based on the actual application's strength requirements and functional needs.

- For load-bearing or areas requiring resistance to significant shear and bending loads (such as aerospace interior panels, floor partitions), it is recommended to choose a total thickness of the honeycomb core and face panels above 10–20 mm, with face panel aluminum foil thickness typically between 0.5–1.0 mm to ensure sufficient deformation resistance;

- For decorative or light thermal and acoustic insulation applications (such as interior ceilings, exhibition partitions), a total thickness of 5–10 mm and face panel aluminum foil thickness of 0.3–0.5 mm can be selected to balance lightweight appearance and basic stability.

- If emphasizing acoustic or thermal insulation performance, the face panel aluminum foil thickness or honeycomb layer height can be appropriately increased, but attention should be paid to the overall weight and cost.

Common market thicknesses for honeycomb aluminum products include 5 mm, 8 mm, 10 mm, 15 mm, and 20 mm. A comprehensive consideration of load-bearing requirements, installation space, budget, and subsequent processing (such as lamination, coating, bending) difficulty is necessary.

Maintenance and Care Methods for Honeycomb Aluminum Foil

- Regular Surface Cleaning: Use mild neutral cleaners (such as neutral detergents) with a soft cloth or sponge to wipe the aluminum foil surface, avoiding hard brushes or strong alkaline or acidic chemicals to prevent damage to the aluminum foil's protective and decorative coatings. Clean from top to bottom, gently wiping along the grain to remove dust, grease, and fingerprints. For stubborn stains on the aluminum foil surface, a damp cloth can be placed for a few minutes before gently wiping.

- Inspect Connections and Edges: Honeycomb aluminum foil is typically fixed to the framework or panels using rivets, adhesives, or specialized pressure strips. It is recommended to inspect the connections with surrounding structures every six months. If rivets are loose, adhesive layers are cracked, or edge seals are detached, they should be promptly reinforced or replaced with sealing strips to prevent moisture or impurities from entering the honeycomb interior, causing core layer corrosion or panel bulging.

- Prevent Prolonged Moisture Exposure: In high-humidity environments (such as kitchens, bathrooms, damp storage), maintain ventilation and avoid direct water spray. Otherwise, the honeycomb core layer may accumulate water, leading to internal aluminum honeycomb oxidation, rust, and delamination. During installation, ventilation holes or drainage holes can be added inside the honeycomb, or waterproof and moisture-resistant coatings can be applied to the aluminum foil surface to extend service life.

- Avoid Sharp Object Scratches: The outer layer of honeycomb aluminum foil is generally thin (0.3–1.0 mm) and should be protected from heavy impacts or sharp object scratches. In automotive, marine, or industrial environments, it is recommended to reinforce high-wear areas (such as walkways, countertops) with anti-slip leather, rubber mats, or protective films.

Precautions for the Use of Honeycomb Aluminum Foil

- Avoid overloading and excessive bending: Although honeycomb aluminum foil has a high strength-to-weight ratio, its bending resistance is closely related to its thickness and the material of the face panel. It is strictly forbidden to place overweight items on the panel or forcibly bend it without evaluating its load-bearing capacity, to prevent internal honeycomb structure collapse or panel cracking.

- Avoid direct high-temperature exposure: While aluminum has good temperature resistance, the internal coating or adhesive of the honeycomb structure may age or fail when the temperature exceeds 80°C. When used outdoors or in high-temperature environments, weather-resistant honeycomb aluminum foil that has passed high-temperature aging tests should be selected, or a sunshade/heat insulation layer should be added to the aluminum foil surface to prevent adhesive layer detachment causing bulging or buckling of the panel.

- Prevent galvanic corrosion: When honeycomb aluminum foil is in direct contact with other metals (such as steel or copper), electrical insulation treatment must be applied; otherwise, galvanic corrosion may occur in humid environments. Insulating pads can be applied to contact surfaces or stainless-steel screws used with anti-corrosion sealant to reduce the potential difference between different metals.

- Pay attention to fire performance: Although most honeycomb aluminum foil cores are aluminum/polyester composites or pure aluminum structures with certain flame retardant properties, the coating or adhesive may affect the overall fire rating. For use in civil buildings or public places, products certified for fire safety (such as Class A fire resistance) should be selected, and fireproof separation gaps and flame-retardant sealants should be reserved as required to ensure that toxic fumes are not rapidly released or fire spread during a fire.

- Regular inspection for aging: Over time, joints, edge sealants, and surface coatings of honeycomb aluminum foil may show signs of peeling, bubbling, or cracking. It is recommended to inspect the surface decorative layer and core bonding condition at least once a year. If significant bulging, delamination, or corrosion is observed, the damaged components should be repaired or replaced promptly to avoid compromising the overall structural safety and aesthetics.

Processing Technology of Honeycomb Aluminum Foil

The manufacturing process starts with aluminum foil (usually alloys such as 3003, 3004, or 5052), where adhesive lines are applied in specific patterns. These foil layers are stacked, bonded, and then expanded to form a honeycomb core with hexagonal cells. The cell size and foil thickness can be adjusted according to specific strength and weight requirements.

Key Steps in the Manufacturing Process

- Surface treatment: The aluminum foil is degreased, pickled, or chemically oxidized to enhance adhesive bonding.

- Gluing and lamination: After longitudinal and transverse gluing, the foils are stacked and thermally pressed to cure.

- Stretching and forming: The core is expanded under high temperature into a honeycomb shape, followed by cutting, welding, and other processing.

The entire process is completed in a modern factory with a high degree of automation.

Performance Advantages of Honeycomb Aluminum Foil

| Characteristics | Specific Performance |

| Lightweight and High Strength | Low density (porous structure), weighs only one-third of steel, with strength close to that of steel. |

| Impact Resistance | The honeycomb structure absorbs impact energy and provides good vibration damping. |

| Thermal and Acoustic Insulation | The sealed air layer inside the honeycomb blocks heat transfer and sound waves, offering excellent insulation. |

| Weather Resistance and Corrosion Protection | Surface treated with epoxy fluorocarbon coating, providing aging resistance and resistance to acid and alkali corrosion. |

| Eco-Friendly and Safe | Free from formaldehyde and radiation, and made from 100% recyclable aluminum. |

Comparison Between Honeycomb Aluminum Foil and Other Materials

Honeycomb Aluminum Foil vs. Regular Aluminum Plate

| Comparison Item | Honeycomb Aluminum Foil | Regular Aluminum Plate |

| Structure & Weight | "Sandwich" honeycomb core structure, panel + honeycomb core; unit area weight is 30%–50% that of regular aluminum plate. | Solid metal plate, typical thickness 0.2–3 mm; relatively heavy. |

| Mechanical Performance | Honeycomb cavities disperse stress, achieving high bending stiffness and compressive strength at low thickness; better deflection and impact resistance. | Bending and compressive strength depends on thickness; thin plates deform easily with limited stiffness. |

| Sound & Thermal Insulation | Honeycomb structure absorbs sound waves, improving sound insulation by 5–8 dB; thermal resistance is 20%–30% higher than that of same-thickness solid aluminum plate. | Poor sound insulation, no sound absorption; high thermal conductivity, weak insulation. |

| Processing & Installation | Lightweight and thin plate, can be cut, machined, and bent as a whole, reducing support structures, with high on-site installation efficiency; process is complex and more costly than regular aluminum plate. | Easy to process, can be cut, punched, bent; thick plate processing consumes more energy; low material cost. |

| Application Fields | Lightweight structures, aircraft cabin walls, exhibitions, office partitions, marine interiors—where weight reduction, rigidity, and aesthetics are needed. | Suitable for metal decorative surfaces, high conductivity or heavy load-bearing situations, such as curtain wall surfaces, billboard back panels. |

Honeycomb Aluminum Foil vs. Fiberglass Reinforced Plastic (FRP)

| Comparison Item | Honeycomb Aluminum Foil | Fiberglass Reinforced Plastic (FRP) |

| Density & Weight | Overall board density about 0.8–1.2 g/cm³, lightweight and high strength; | Density about 1.6–2.0 g/cm³, roughly 1.5 times heavier than honeycomb aluminum foil. |

| Mechanical Performance | Metal honeycomb structure offers high strength-to-stiffness ratio, excellent in-plane force performance; | Good stiffness, but in-plane stiffness weaker than honeycomb aluminum foil of the same thickness. |

| Weather & Corrosion Resistance | Aluminum alloy panels can be anodized or PVDF coated, excellent corrosion and UV aging resistance; | Naturally chemically resistant, electrically insulating; but resin matrix tends to yellow and age under UV exposure. |

| Surface Decoration | Optional PVDF coatings, stainless aluminum surfaces, diverse and consistent colors; | Surface requires spraying or film covering; metallic texture requires additional processes. |

| Structural Use & Installation | Easy processing for flat or slightly curved surfaces, commonly installed using clips or hangers; good fire resistance; | One-time molding, can form complex curves; burns rapidly and produces smoke during fires. |

| Cost & Maintenance | Higher material cost, but fast installation and easy maintenance; scratched panels can be individually replaced; | Low raw material and mold costs, suitable for mass production; surface cracks require glue repair and repainting, maintenance more cumbersome. |

Honeycomb Aluminum Foil vs. Stone

| Comparison Item | Honeycomb Aluminum Foil | Stone (Granite, Marble, etc.) |

| Weight & Load Requirements | Overall density around 0.8–1.2 g/cm³, only a few kilograms per square meter; reduces structural load, low transport and hoisting cost. | Density of 2.6–2.8 g/cm³, several tens of kilograms per square meter; requires reinforced framework and support systems. |

| Weather Resistance & Durability | High-quality fluorocarbon-coated panels, UV and oxidation resistant, lifespan of 20–30 years; damaged panels can be locally replaced. | Naturally weather and erosion resistant, but vulnerable to acid rain and pollutants; cracks or seepage require specialized protection and repair. |

| Decorative Effect & Consistency | Factory batch spraying ensures color consistency, surface textures can be CNC-processed, various finishes available; suitable for large, uniform decorative surfaces. | Natural luxurious textures, each piece has unique patterns and color differences during splicing; limited suitability for curved surfaces. |

| Installation & Construction | Easy to install, lightweight panels can use clips or hangers; construction time can be reduced by 20%–30%. | Complicated process (cutting, edging, dry-hanging), long duration and labor intensive. |

| Safety & Sustainability | Lightweight material, low kinetic energy if detached; recyclable and aligned with green building standards. | Heavy, high risk if falling; difficult to recycle, results in resource waste. |

Honeycomb Aluminum Foil Standards & Testing

- Mechanical Testing: Shear strength (up to 380 psi), compressive strength (up to 640 psi), and other strength metrics validated according to density/cell size.

- Export Compliance: Packaged in wooden crates/pallets, oil-free surface, corrosion protection.