As a leading manufacturer of anodized aluminum sheets, Haomei Aluminum provides high-quality and precision-engineered products with industry-leading surface treatment technology. Every sheet is carefully crafted to ensure excellent corrosion resistance, vibrant color stability, and a flawless surface finish.

Our anodized aluminum sheets are widely used and are the ideal choice for building facades, signage, electronic device housings, and home appliance panels.

What is Anodized Aluminum Sheet?

An anodized aluminum sheet is a high-performance material that forms an oxide film on the aluminum surface through an electrolytic process. Its core advantages lie in the perfect combination of corrosion resistance, decorative appeal, and functionality.

Properties of the Oxide Film

This oxide film is not an additional coating but is formed by the oxidation reaction of the aluminum itself, therefore bonding tightly with the aluminum substrate, with extremely high stability and durability. During anodizing, the thickness of the aluminum oxide layer formed on the sheet surface is usually 5-20 microns, while hard anodizing films can reach 60-200 microns.

This oxide film not only improves the hardness and wear resistance of the aluminum sheet but also significantly enhances its corrosion resistance, insulation, and decorative effect. The core feature of anodized aluminum sheets is that the oxide film is formed from the aluminum itself, so it will not peel or flake off like coatings, and has excellent adhesion and stability.

Process Principle

The principle of anodizing aluminum sheets is based on the fundamentals of water electrolysis. When current passes through, hydrogen gas is released at the cathode, while oxygen precipitates at the anode not only in molecular form but also as atomic oxygen (O) and ionic oxygen. These oxygen species react with aluminum, which serves as the anode, to form an anhydrous aluminum oxide film. Not all the generated oxygen reacts with aluminum; part of it is released in gaseous form.

As a high-performance metallic material, anodized aluminum sheets form a tightly bonded aluminum oxide film through a unique anodizing process, featuring high strength, high hardness, excellent corrosion resistance, and weather resistance. With a wide range of alloy grades, diverse surface colors, and complete specifications, they meet the needs of various application fields.

When choosing anodized aluminum sheets, it is necessary to comprehensively consider application scenarios, alloy grades, thickness, surface treatment process, color, and appearance to ensure that the selected product meets practical requirements. At the same time, attention should be paid to preventing and solving common issues during use, so as to fully utilize the superior performance of anodized aluminum sheets and extend their service life.

Anodized Aluminum Sheet Alloys Guide

Popular Anodized Aluminum Sheet Alloys

Anodized aluminum sheets can be manufactured from various aluminum alloys, and different alloy grades have different characteristics and application scenarios. The following are several common anodized aluminum sheet alloy grades and their features:

1 Series Pure Aluminum Sheets

1 series aluminum alloys contain the highest aluminum content, usually above 99.00%. These alloys have excellent corrosion resistance and outstanding workability, making them an ideal choice for anodizing treatment.

- 1060 Aluminum Sheet: Aluminum content 99.60%, with good formability, corrosion resistance, and weldability.

- 1100 Aluminum Sheet: Aluminum content 99.00%, relatively low strength but excellent formability and corrosion resistance.

3 Series Aluminum-Manganese Alloys

3 series aluminum alloys mainly add manganese, featuring medium strength and good corrosion resistance:

- 3003 Aluminum Sheet: The most commonly used aluminum-manganese alloy, with good workability and corrosion resistance.

- 3004 Aluminum Sheet: Added with magnesium, stronger than 3003, commonly used for building curtain walls.

5 Series Aluminum-Magnesium Alloys

5 series aluminum alloys are alloyed with magnesium, offering medium strength and excellent corrosion resistance:

- 5005 Aluminum Sheet: Magnesium content about 1.0%, commonly used in architectural decoration.

- 5052 Aluminum Sheet: Magnesium content about 2.5%, one of the most widely used alloys in the 5 series.

- 5083 Aluminum Sheet: Magnesium content about 4.0%, high strength, and excellent corrosion resistance.

6 Series Aluminum-Magnesium-Silicon Alloys

6 series aluminum alloys contain magnesium and silicon, can be heat-treated for strengthening, and have relatively high strength:

- 6061 Aluminum Sheet: The most commonly used 6 series alloy with excellent comprehensive properties.

- 6063 Aluminum Sheet: Slightly lower strength than 6061 but with better surface finish.

- 6082 Aluminum Sheet: Higher strength than 6061 and good weldability.

Anodizing 7000 Series Aluminum

7 series aluminum alloys are alloyed with zinc and are the highest-strength aluminum alloy series:

7075 Aluminum Sheet: Offers extremely high strength and hardness, suitable for aerospace applications.

Popular Anodized Aluminum Sheet Alloys from Haomei

- 6061 Anodized Aluminum SheetPremium 6061 anodized aluminum sheet offers outstanding corrosion resistance and reliable mechanical strength. Perfect for aerospace, automotive, and structural applications, it ensures both durability and an attractive surface finish.

- 6061-T6 Anodized Aluminum Sheet6061-T6 anodized aluminum sheet delivers superior tensile strength and wear resistance, making it ideal for precision machinery, automotive components, and robust structural frameworks that demand high performance.

- 6063 Anodized Aluminum Sheet6063 anodized aluminum sheet combines smooth surface finish with excellent corrosion resistance. Widely used in architectural projects, window frames, and decorative facades, it enhances both aesthetics and longevity.

- 1050 Anodized Aluminum Sheet1050 anodized aluminum sheet, with its high purity and exceptional corrosion resistance, is perfect for chemical equipment, signage, and decorative panels, providing a lightweight yet durable solution.

- 1060 Anodized Aluminum Sheet1060 anodized aluminum sheet features excellent formability and corrosion resistance, making it an ideal choice for roofing, cladding, building projects, and electrical or food-processing equipment.

- 1100 Anodized Aluminum Sheet1100 anodized aluminum sheet is a commercially pure alloy known for superior corrosion resistance and easy workability. Ideal for roofing, siding, signage, and kitchen equipment where durability meets design.

- 3003 Anodized Aluminum Sheet3003 anodized aluminum sheet combines enhanced strength with excellent corrosion resistance. It is the preferred solution for roofing, siding, and marine applications where long-lasting performance is essential.

- 5005 Anodized Aluminum Sheet5005 anodized aluminum sheet provides high corrosion resistance and a flawless surface finish. Perfect for exterior architectural panels, facades, and decorative applications that require both beauty and durability.

- 5052 Anodized Aluminum Sheet5052 anodized aluminum sheet offers exceptional corrosion resistance and fatigue strength. Ideal for marine environments, fuel tanks, and chemical equipment, it ensures long-term reliability under challenging conditions.

- 7075 Anodized Aluminum Sheet7075 anodized aluminum sheet is a high-strength alloy designed for maximum performance. Widely used in aerospace, defense, and structural applications where superior strength-to-weight ratio is critical.

- 2024 Anodized Aluminum Sheet2024 anodized aluminum sheet provides excellent fatigue resistance and high strength. Perfect for aerospace, military, and high-stress structural components requiring dependable performance.

- A380 Anodized Aluminum SheetA380 anodized aluminum sheet, an aluminum-silicon-copper casting alloy, combines corrosion resistance with a smooth surface finish. Ideal for automotive parts, precision castings, and machinery components where quality matters.

Anodized Aluminum Sheet Color Options

The surface color of anodized aluminum sheets mainly depends on the anodizing process and subsequent treatment methods. According to different techniques and requirements, anodized aluminum sheets can present a wide variety of color effects.

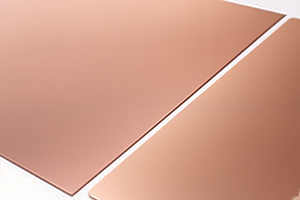

Natural Color Series

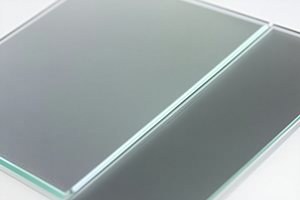

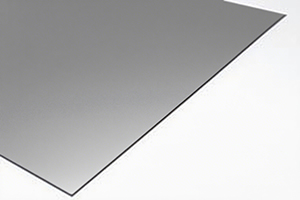

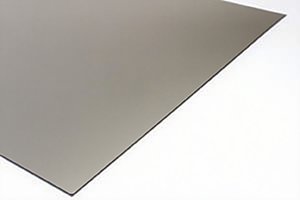

- Silver White: The most common natural color, obtained from pure aluminum or low-alloy aluminum alloys.

- Gray Shades: Includes light gray, medium gray, and dark gray tones of varying depth.

- Champagne: A light gray with golden tones, offering a warm and elegant visual effect.

Metallic Color Series

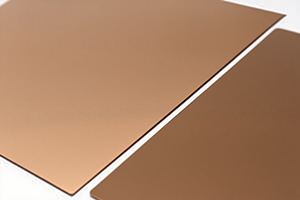

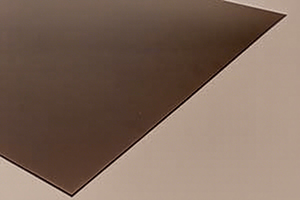

- Bronze Shades: Includes light bronze, medium bronze, and dark bronze in multiple tones.

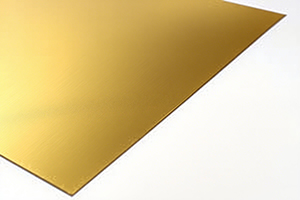

- Gold Shades: Includes light gold, medium golden yellow, and deep gold tones of different depths.

- Titanium Gold: A gold with silver undertones, featuring a unique metallic texture.

- Rose Gold: A gold with pink undertones, very popular in recent years.

Color Series

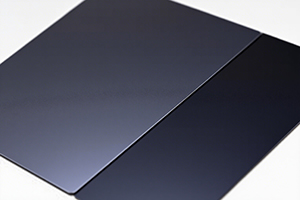

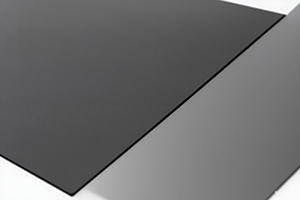

- Black Shades: Includes matte black, glossy black, and deep black in various depths.

- Blue Shades: Includes light blue, dark blue, and steel blue in different tones.

- Red Shades: Includes light red, deep red, and rose red in multiple tones.

- Green Shades: Includes light green, dark green, and grass green in different variations.

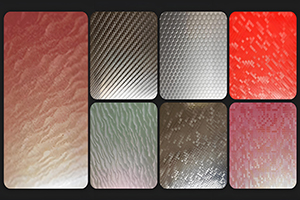

Special Effect Colors

- Wood Grain Effect: Achieves realistic wood textures through special processing techniques.

- Stone Grain Effect: Simulates the patterns and textures of various natural stones.

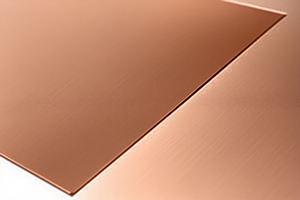

- Brushed Effect: Creates uniform linear textures with a brushed metal appearance.

- Mirror Effect: Achieves a highly reflective, mirror-like surface through precision polishing.

-

Black Anodized Aluminum Sheet

-

Clear Anodized Aluminum Sheet

-

Gold Anodized Aluminum Sheet

-

Silver Anodized Aluminum Sheet

-

Bronze Anodized Aluminum Sheet

-

Dark Bronze Anodized Aluminum Sheet

-

Red Anodized Aluminum Sheet

-

Blue Anodized Aluminum Sheet

-

Green Anodized Aluminum Sheet

-

Yellow Anodized Aluminum Sheet

-

Orange Anodized Aluminum Sheet

-

Pink Anodized Aluminum Sheet

-

Rose Gold Anodized Aluminum Sheet

-

Copper Anodized Aluminum Sheet

-

Grey Anodized Aluminum Sheet

-

Dark Anodized Aluminum Sheet

-

Matte Black Anodized Aluminum Sheet

-

Satin Anodized Aluminum Sheet

-

Brown Anodized Aluminum Sheet

-

White Anodized Aluminum Sheet

Color Stability Tips

The colors produced by electrolytic coloring have better lightfastness and weather resistance compared to organic dye coloring, making them more suitable for outdoor applications. In addition, anodized aluminum sheets that undergo sealing treatment have higher color stability, effectively preventing fading and discoloration.

Anodized Aluminum Sheet Specifications and Sizes

Thickness Specifications

- Thin Sheet: 0.2-3.0mm, used for decoration and electronic product housings.

- Medium-Thickness Sheet: 3.0-8.0mm, used for building curtain walls and furniture panels.

- Thick Sheet: Above 8.0mm, used for structural components and special equipment parts.

Width Specifications

- Narrow Sheet: 20-1000mm, used for special decorations and small equipment.

- Medium-Width Sheet: 1000-2000mm, the most common width specification.

- Wide Sheet: 2000-2650mm, used for large building curtain walls.

Length Specifications

- Short Length Sheet: 400-2000mm, used for small decorations and small equipment.

- Medium to Long Length Sheet: 2000-6000mm, the most common length specification.

- Extra-Long Sheet: Above 6000mm, used for large building curtain walls.

Standard Size Specifications

- 48×96 inches (approx. 1220×2440mm)

- 48×120 inches (approx. 1220×3050mm), etc.

Custom Specifications

- Thickness Customization: Minimum thickness 0.02mm, maximum thickness 12.00mm.

- Width Customization: Minimum width 20mm, maximum width 2600mm.

- Length Customization: Minimum length 20mm, maximum length 8000mm.

Anodized Aluminum Sheet Surface Treatments

Mirror Anodized Aluminum Sheet

Mirror anodized aluminum sheet features a highly reflective, smooth surface that enhances aesthetics and adds a premium look, ideal for decorative panels, signage, and interior design applications.

Color-Anodized Aluminum Sheet

Color-anodized aluminum sheet offers vibrant and durable color options, providing both visual appeal and long-lasting corrosion resistance for architectural facades, furniture, and custom design projects.

Brushed-Finish Anodized Aluminum Sheet

Brushed-finish anodized aluminum sheet presents a subtle, linear texture that reduces fingerprints and glare while maintaining excellent corrosion resistance, perfect for electronics enclosures, appliances, and interior panels.

Matte-Finish Anodized Aluminum Sheet

Matte-finish anodized aluminum sheet delivers a smooth, non-reflective surface with consistent color stability, making it suitable for modern architectural applications, signage, and decorative cladding.

Embossed-Pattern Anodized Aluminum Sheet

Embossed-pattern anodized aluminum sheet features raised or textured designs, adding visual interest and improved scratch resistance, ideal for decorative panels, facades, and interior applications.

Double-Sided Anodized Aluminum Sheet

Double-sided anodized aluminum sheet provides uniform anodized protection on both surfaces, offering enhanced corrosion resistance and aesthetic appeal for applications like partitions, panels, and high-end architectural projects.

PVDF-Coated Anodized Aluminum Sheet

PVDF-coated anodized aluminum sheet combines anodization with a protective PVDF coating, delivering superior weather resistance, color retention, and durability for exterior architectural cladding and signage.

Hard-Anodized Aluminum Sheet

Hard-anodized aluminum sheet features a thick, wear-resistant anodic layer, providing exceptional hardness, scratch resistance, and durability for industrial applications, machinery parts, and high-traffic surfaces.

Anti-Fingerprint Anodized Aluminum Sheet

Anti-fingerprint anodized aluminum sheet is treated to minimize smudges and fingerprints while maintaining corrosion resistance and surface finish, ideal for consumer electronics, appliances, and frequently handled surfaces.

Properties of Anodized Aluminum Sheet

High Strength and Hardness

The hardness of the oxide film reaches gemstone-level hardness (about 9 on the Mohs scale). Hard anodized films can achieve hardness above HV300, significantly improving the material’s wear resistance and scratch resistance.

Excellent Corrosion Resistance

The oxide film can withstand thousands of hours in a ω=0.03NaCl salt spray environment without corrosion. It resists acid rain, chemicals, seawater, and various corrosive media, providing a service life of more than 20 years.

Good Weather Resistance

Long-term indoor use does not cause discoloration or corrosion. For outdoor applications, anodized aluminum sheets with a thick oxide film (10μm) can maintain their color even under prolonged sunlight exposure.

Excellent Fire Resistance

The surface contains no paint or chemical substances and can withstand temperatures up to 600°C without burning. It does not produce toxic gases under high heat, fully meeting fire safety and environmental standards.

Good Insulation Performance

The breakdown voltage of the oxide film reaches up to 2000V, giving it excellent insulation properties, especially suitable for electrical applications requiring insulation.

Outstanding Thermal Stability

The melting point of the hard anodized film is as high as 2320K (about 2047℃), with extremely high thermal stability. Its thermal expansion coefficient is close to that of the aluminum substrate, effectively avoiding stress and deformation caused by temperature changes.

Good Workability

Anodized aluminum sheets have strong decorative appeal and moderate hardness. They can be easily bent and formed, used in continuous high-speed stamping, and processed by cutting, punching, engraving, and rolling.

Attractive Decorative Performance

The oxide film surface retains the metallic luster and texture of the aluminum sheet, giving a high-end and modern appearance. Through dyeing processes, various colors can be achieved with fine surface texture and high gloss.

Environmental Protection and Sustainability

The anodizing process does not use organic coatings, fully complying with green building requirements for eco-friendly materials. Aluminum itself is recyclable, making it a sustainable green building material.

Applications of Anodized Aluminum

Architectural Decoration

- Building curtain walls

- Ceilings

- Interior wall decoration

- Door and window frames

- Balconies and railings

Electronics and Electrical

- Electronic product housings

- Electrical panels

- Lighting equipment

- Electronic components

Transportation

- Automobile manufacturing

- Rail transit

- Shipbuilding

- Aerospace

Industrial Equipment

- Machinery enclosures

- Instruments and meters

- Pipelines and containers

- Heat dissipation components

Advertising and Signage

- Outdoor billboards

- Signs and plaques

- Display racks and cabinets

Furniture and Interior Decoration

- Furniture panels

- Decorative trims

- Decorative ornaments

- Bathroom fixtures

Anodized Aluminum Sheet for Architectural Decoration

Anodized aluminum sheets provide durable, corrosion-resistant, and aesthetically appealing surfaces, perfect for architectural facades, curtain walls, and decorative cladding.

Anodized Aluminum Sheet for Electronic Product Housings

Anodized aluminum sheets offer excellent surface finish, scratch resistance, and durability, making them ideal for electronic device enclosures and consumer electronics.

Anodized Aluminum Sheet for Automobiles

Anodized aluminum sheets deliver corrosion resistance, lightweight strength, and attractive appearance, suitable for automotive body panels, trims, and decorative components.

Anodized Aluminum Sheet for Machinery Enclosures

Anodized aluminum sheets provide wear resistance, corrosion protection, and structural strength, perfect for industrial machinery housings and equipment panels.

Anodized Aluminum Plaques

Anodized aluminum sheets are ideal for plaques and signage, offering vibrant color retention, durability, and a professional, polished appearance.

Anodized Aluminum Sheet for Furniture Panels

Anodized aluminum sheets enhance furniture with corrosion-resistant, visually appealing surfaces, suitable for cabinets, partitions, and decorative panels.

Hot-Selling 5005 Anodized Aluminum Sheet Sizes

| Product | Thickness | Size | Color |

| 0.032" Anodized Aluminum Sheet Gold 5005 | 0.032" | 12″ X 12″ (1 X 1 ft.) | Gold |

| 0.032" Anodized Aluminum Sheet Gold 5005 | 0.032" | 12″ X 24″ (1 X 2 ft.) | Gold |

| 0.032" Anodized Aluminum Sheet Gold 5005 | 0.032" | 12″ X 36″ (1 X 3 ft.) | Gold |

| 0.032" Anodized Aluminum Sheet Gold 5005 | 0.032" | 12″ X 48″ (1 X 4 ft.) | Gold |

| 0.032" Anodized Aluminum Sheet Gold 5005 | 0.032" | 24″ X 24″ (2 X 2 ft.) | Gold |

| 0.032" Anodized Aluminum Sheet Gold 5005 | 0.032" | 24″ X 36″ (2 X 3 ft.) | Gold |

| 0.032" Anodized Aluminum Sheet Gold 5005 | 0.032" | 24″ X 48″ (2 X 4 ft.) | Gold |

| 0.032" Anodized Aluminum Sheet Gold 5005 | 0.032" | 36″ X 36″ (3 X 3 ft.) | Gold |

| 0.032" Anodized Aluminum Sheet Gold 5005 | 0.032" | 36″ X 48″ (3 X 4 ft.) | Gold |

| 0.032" Anodized Aluminum Sheet Gold 5005 | 0.032" | 48″ X 120″ (4 X 10 ft.) | Gold |

| 0.04" Anodized Aluminum Sheet Clear 5005 | 0.04" | 12″ X 12″ (1 X 1 ft.) | Clear |

| 0.04" Anodized Aluminum Sheet Clear 5005 | 0.04" | 12″ X 24″ (1 X 2 ft.) | Clear |

| 0.04" Anodized Aluminum Sheet Clear 5005 | 0.04" | 12″ X 36″ (1 X 3 ft.) | Clear |

| 0.04" Anodized Aluminum Sheet Clear 5005 | 0.04" | 12″ X 48″ (1 X 4 ft.) | Clear |

| 0.04" Anodized Aluminum Sheet Clear 5005 | 0.04" | 24″ X 24″ (2 X 2 ft.) | Clear |

| 0.04" Anodized Aluminum Sheet Clear 5005 | 0.04" | 24″ X 36″ (2 X 3 ft.) | Clear |

| 0.04" Anodized Aluminum Sheet Clear 5005 | 0.04" | 24″ X 48″ (2 X 4 ft.) | Clear |

| 0.04" Anodized Aluminum Sheet Clear 5005 | 0.04" | 36″ X 36″ (3 X 3 ft.) | Clear |

| 0.04" Anodized Aluminum Sheet Clear 5005 | 0.04" | 36″ X 48″ (3 X 4 ft.) | Clear |

| 0.04" Anodized Aluminum Sheet Clear 5005 | 0.04" | 48″ X 120″ (4 X 10 ft.) | Clear |

| 0.04" Anodized Aluminum Sheet Dark Bronze 5005 | 0.04" | 12″ X 12″ (1 X 1 ft.) | Dark Bronze |

| 0.04" Anodized Aluminum Sheet Dark Bronze 5005 | 0.04" | 12″ X 24″ (1 X 2 ft.) | Dark Bronze |

| 0.04" Anodized Aluminum Sheet Dark Bronze 5005 | 0.04" | 12″ X 36″ (1 X 3 ft.) | Dark Bronze |

| 0.04" Anodized Aluminum Sheet Dark Bronze 5005 | 0.04" | 12″ X 48″ (1 X 4 ft.) | Dark Bronze |

| 0.04" Anodized Aluminum Sheet Dark Bronze 5005 | 0.04" | 24″ X 24″ (2 X 2 ft.) | Dark Bronze |

| 0.04" Anodized Aluminum Sheet Dark Bronze 5005 | 0.04" | 24″ X 36″ (2 X 3 ft.) | Dark Bronze |

| 0.04" Anodized Aluminum Sheet Dark Bronze 5005 | 0.04" | 24″ X 48″ (2 X 4 ft.) | Dark Bronze |

| 0.04" Anodized Aluminum Sheet Dark Bronze 5005 | 0.04" | 36″ X 36″ (3 X 3 ft.) | Dark Bronze |

| 0.04" Anodized Aluminum Sheet Dark Bronze 5005 | 0.04" | 36″ X 48″ (3 X 4 ft.) | Dark Bronze |

| 0.04" Anodized Aluminum Sheet Dark Bronze 5005 | 0.04" | 48″ X 120″ (4 X 10 ft.) | Dark Bronze |

| 0.04" Anodized Aluminum Sheet Black 5005 | 0.04" | 12″ X 12″ (1 X 1 ft.) | Black |

| 0.04" Anodized Aluminum Sheet Black 5005 | 0.04" | 12″ X 24″ (1 X 2 ft.) | Black |

| 0.04" Anodized Aluminum Sheet Black 5005 | 0.04" | 12″ X 36″ (1 X 3 ft.) | Black |

| 0.04" Anodized Aluminum Sheet Black 5005 | 0.04" | 12″ X 48″ (1 X 4 ft.) | Black |

| 0.04" Anodized Aluminum Sheet Black 5005 | 0.04" | 24″ X 24″ (2 X 2 ft.) | Black |

| 0.04" Anodized Aluminum Sheet Black 5005 | 0.04" | 24″ X 36″ (2 X 3 ft.) | Black |

| 0.04" Anodized Aluminum Sheet Black 5005 | 0.04" | 24″ X 48″ (2 X 4 ft.) | Black |

| 0.04" Anodized Aluminum Sheet Black 5005 | 0.04" | 36″ X 36″ (3 X 3 ft.) | Black |

| 0.04" Anodized Aluminum Sheet Black 5005 | 0.04" | 36″ X 48″ (3 X 4 ft.) | Black |

| 0.04" Anodized Aluminum Sheet Black 5005 | 0.04" | 48″ X 120″ (4 X 10 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Dark Bronze 5005 | 0.063" | 12″ X 12″ (1 X 1 ft.) | Dark Bronze |

| 0.063" Anodized Aluminum Sheet Dark Bronze 5005 | 0.063" | 12″ X 24″ (1 X 2 ft.) | Dark Bronze |

| 0.063" Anodized Aluminum Sheet Dark Bronze 5005 | 0.063" | 12″ X 36″ (1 X 3 ft.) | Dark Bronze |

| 0.063" Anodized Aluminum Sheet Dark Bronze 5005 | 0.063" | 12″ X 48″ (1 X 4 ft.) | Dark Bronze |

| 0.063" Anodized Aluminum Sheet Dark Bronze 5005 | 0.063" | 24″ X 24″ (2 X 2 ft.) | Dark Bronze |

| 0.063" Anodized Aluminum Sheet Dark Bronze 5005 | 0.063" | 24″ X 36″ (2 X 3 ft.) | Dark Bronze |

| 0.063" Anodized Aluminum Sheet Dark Bronze 5005 | 0.063" | 24″ X 48″ (2 X 4 ft.) | Dark Bronze |

| 0.063" Anodized Aluminum Sheet Dark Bronze 5005 | 0.063" | 36″ X 36″ (3 X 3 ft.) | Dark Bronze |

| 0.063" Anodized Aluminum Sheet Dark Bronze 5005 | 0.063" | 36″ X 48″ (3 X 4 ft.) | Dark Bronze |

| 0.063" Anodized Aluminum Sheet Dark Bronze 5005 | 0.063" | 48″ X 120″ (4 X 10 ft.) | Dark Bronze |

| 0.063" Anodized Aluminum Sheet Clear 5005 | 0.063" | 12″ X 12″ (1 X 1 ft.) | Clear |

| 0.063" Anodized Aluminum Sheet Clear 5005 | 0.063" | 12″ X 24″ (1 X 2 ft.) | Clear |

| 0.063" Anodized Aluminum Sheet Clear 5005 | 0.063" | 12″ X 36″ (1 X 3 ft.) | Clear |

| 0.063" Anodized Aluminum Sheet Clear 5005 | 0.063" | 12″ X 48″ (1 X 4 ft.) | Clear |

| 0.063" Anodized Aluminum Sheet Clear 5005 | 0.063" | 24″ X 24″ (2 X 2 ft.) | Clear |

| 0.063" Anodized Aluminum Sheet Clear 5005 | 0.063" | 24″ X 36″ (2 X 3 ft.) | Clear |

| 0.063" Anodized Aluminum Sheet Clear 5005 | 0.063" | 24″ X 48″ (2 X 4 ft.) | Clear |

| 0.063" Anodized Aluminum Sheet Clear 5005 | 0.063" | 36″ X 36″ (3 X 3 ft.) | Clear |

| 0.063" Anodized Aluminum Sheet Clear 5005 | 0.063" | 36″ X 48″ (3 X 4 ft.) | Clear |

| 0.063" Anodized Aluminum Sheet Clear 5005 | 0.063" | 48″ X 120″ (4 X 10 ft.) | Clear |

| 0.063" Anodized Aluminum Sheet Black 5005 | 0.063" | 12″ X 12″ (1 X 1 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Black 5005 | 0.063" | 12″ X 24″ (1 X 2 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Black 5005 | 0.063" | 12″ X 36″ (1 X 3 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Black 5005 | 0.063" | 12″ X 48″ (1 X 4 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Black 5005 | 0.063" | 24″ X 24″ (2 X 2 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Black 5005 | 0.063" | 24″ X 36″ (2 X 3 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Black 5005 | 0.063" | 24″ X 48″ (2 X 4 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Black 5005 | 0.063" | 36″ X 36″ (3 X 3 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Black 5005 | 0.063" | 36″ X 48″ (3 X 4 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Black 5005 | 0.063" | 48″ X 120″ (4 X 10 ft.) | Black |

| 0.063" Anodized Aluminum Sheet Gold 5005 | 0.063" | 12″ X 12″ (1 X 1 ft.) | Gold |

| 0.063" Anodized Aluminum Sheet Gold 5005 | 0.063" | 12″ X 24″ (1 X 2 ft.) | Gold |

| 0.063" Anodized Aluminum Sheet Gold 5005 | 0.063" | 12″ X 36″ (1 X 3 ft.) | Gold |

| 0.063" Anodized Aluminum Sheet Gold 5005 | 0.063" | 12″ X 48″ (1 X 4 ft.) | Gold |

| 0.063" Anodized Aluminum Sheet Gold 5005 | 0.063" | 24″ X 24″ (2 X 2 ft.) | Gold |

| 0.063" Anodized Aluminum Sheet Gold 5005 | 0.063" | 24″ X 36″ (2 X 3 ft.) | Gold |

| 0.063" Anodized Aluminum Sheet Gold 5005 | 0.063" | 24″ X 48″ (2 X 4 ft.) | Gold |

| 0.063" Anodized Aluminum Sheet Gold 5005 | 0.063" | 36″ X 36″ (3 X 3 ft.) | Gold |

| 0.063" Anodized Aluminum Sheet Gold 5005 | 0.063" | 36″ X 48″ (3 X 4 ft.) | Gold |

| 0.063" Anodized Aluminum Sheet Gold 5005 | 0.063" | 48″ X 120″ (4 X 10 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Gold 5005 | 1/8" | 12″ X 12″ (1 X 1 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Gold 5005 | 1/8" | 12″ X 24″ (1 X 2 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Gold 5005 | 1/8" | 12″ X 36″ (1 X 3 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Gold 5005 | 1/8" | 12″ X 48″ (1 X 4 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Gold 5005 | 1/8" | 24″ X 24″ (2 X 2 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Gold 5005 | 1/8" | 24″ X 36″ (2 X 3 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Gold 5005 | 1/8" | 24″ X 48″ (2 X 4 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Gold 5005 | 1/8" | 36″ X 36″ (3 X 3 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Gold 5005 | 1/8" | 36″ X 48″ (3 X 4 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Gold 5005 | 1/8" | 48″ X 120″ (4 X 10 ft.) | Gold |

| 1/8" Anodized Aluminum Sheet Clear 5005 | 1/8" | 12″ X 12″ (1 X 1 ft.) | Clear |

| 1/8" Anodized Aluminum Sheet Clear 5005 | 1/8" | 12″ X 24″ (1 X 2 ft.) | Clear |

| 1/8" Anodized Aluminum Sheet Clear 5005 | 1/8" | 12″ X 36″ (1 X 3 ft.) | Clear |

| 1/8" Anodized Aluminum Sheet Clear 5005 | 1/8" | 12″ X 48″ (1 X 4 ft.) | Clear |

| 1/8" Anodized Aluminum Sheet Clear 5005 | 1/8" | 24″ X 24″ (2 X 2 ft.) | Clear |

| 1/8" Anodized Aluminum Sheet Clear 5005 | 1/8" | 24″ X 36″ (2 X 3 ft.) | Clear |

| 1/8" Anodized Aluminum Sheet Clear 5005 | 1/8" | 24″ X 48″ (2 X 4 ft.) | Clear |

| 1/8" Anodized Aluminum Sheet Clear 5005 | 1/8" | 36″ X 36″ (3 X 3 ft.) | Clear |

| 1/8" Anodized Aluminum Sheet Clear 5005 | 1/8" | 36″ X 48″ (3 X 4 ft.) | Clear |

| 1/8" Anodized Aluminum Sheet Clear 5005 | 1/8" | 48″ X 120″ (4 X 10 ft.) | Clear |

How to Choose Anodized Aluminum Sheets

Choose Based on Application Scenarios

- Architectural Decoration: Select products with good weather resistance and high color stability

- Electronic Products: Select products with good conductivity and excellent heat dissipation

- Transportation: Select products that are lightweight, high-strength, and corrosion-resistant

- Industrial Equipment: Select products with good wear resistance and strong corrosion resistance

Select the Appropriate Alloy Grade

- 1xxx Series Pure Aluminum Sheets: Suitable for applications requiring high corrosion resistance

- 3xxx Series Aluminum-Manganese Alloys: Suitable for decorative applications requiring certain strength

- 5xxx Series Aluminum-Magnesium Alloys: Widely used in construction and decorative fields

- 6xxx Series Aluminum-Magnesium-Silicon Alloys: Suitable for structural applications requiring high strength

- 7xxx Series High-Strength Alloys: Suitable for aerospace and high-end industrial applications

Determine the Suitable Thickness

- Thin Sheets (0.2-3.0mm): Used for decoration and electronic product housings

- Medium-Thickness Sheets (3.0-8.0mm): Used for building curtain walls and furniture panels

- Thick Sheets (above 8.0mm): Used for structural components and special equipment parts

Consider the Oxide Film Thickness

- Thin Oxide Film (5-10μm): Suitable for indoor decoration

- Medium Oxide Film (10-20μm): Suitable for general outdoor environments

- Thick Oxide Film (above 20μm): Suitable for harsh environments

Select the Appropriate Surface Treatment Process

- Standard Anodizing: Suitable for general applications

- Hard Anodizing: Suitable for high-wear applications

- Dyed Anodizing: Suitable for applications requiring a wide range of colors

- Brushed Anodizing: Suitable for applications requiring special textures

- Mirror Anodizing: Suitable for applications requiring high gloss

Consider Color and Appearance Requirements

- Color Options: Choose solid colors, gradient colors, or patterned colors according to design needs

- Surface Finish: Choose matte, glossy, brushed, sandblasted, etc.

- Color Difference Control: Ensure color difference ΔE≤1.0 within the same batch

Anodized Aluminum Sheet FAQs

Oxide Film Discoloration Issues

- Cause Analysis: Changes in electrolyte composition, temperature fluctuations, uneven current density, improper dyeing process control, long-term UV exposure, etc.

- Solutions: Choose products with stable quality, prioritize electrolytic coloring products, avoid prolonged strong UV exposure, clean regularly.

Oxide Film Corrosion Issues

- Cause Analysis: Long-term exposure to corrosive environments, insufficient oxide film thickness, improper sealing treatment, mechanical damage, etc.

- Solutions: Choose the appropriate oxide film thickness, ensure sealing quality, avoid direct contact with corrosive substances, clean corrosion products in time.

Oxide Film Cracking and Peeling Issues

- Cause Analysis: Stress caused by temperature changes, excessive mechanical stress, insufficient bonding between oxide film and substrate, excessive bending during processing, etc.

- Solutions: Choose products with strong adhesion between oxide film and substrate, avoid excessive temperature fluctuations and mechanical stress, carry out timely repair.

Color Difference Issues

- Cause Analysis: Process parameter differences between different production batches, alloy composition variations, uneven oxide film thickness, dyeing parameter fluctuations, etc.

- Solutions: Purchase from the same batch whenever possible, specify color difference requirements, reserve enough margin, adjust installation sequence.

Surface Scratch Issues

- Cause Analysis: Friction and collisions during handling and installation, scratches by sharp objects during use, use of hard tools during cleaning, etc.

- Solutions: Use soft materials to protect the surface, avoid using sharp tools, use soft cloths and neutral detergents for regular cleaning.

Insufficient Adhesion of Oxide Film

- Cause Analysis: Incomplete pretreatment of aluminum surface, inappropriate electrolyte composition, improper control of anodizing parameters, improper sealing treatment, etc.

- Solutions: Choose reliable quality products, inspect quality before installation, avoid using strong corrosive cleaning agents.

Why Choose Haomei for Anodized Aluminum Sheets

Excellent Quality of Anodized Aluminum Sheets

At Haomei, we prioritize rigorous performance testing and industry certifications to ensure that every anodized aluminum sheet meets the highest standards:

- Corrosion Resistance: Our sheets undergo salt spray testing, ensuring long-lasting durability even in harsh environments.

- Wear Resistance: The surface remains tough even after daily wear and tear.

- Color Stability: UV aging tests ensure that the anodized aluminum surface remains durable with a vibrant and bright appearance.

- Surface Hardness: Vickers hardness tests verify superior surface strength, extending the service life.

- Fire Resistance: For architectural applications, our anodized aluminum sheets meet strict fire safety requirements.

We are committed to providing customers with reliable products:

- Certified Manufacturing: Haomei is ISO9001 certified, reflecting our strict quality management system.

- Advanced Production Capability: We are equipped with state-of-the-art facilities to ensure timely delivery of high-quality sheets.

- Comprehensive After-Sales Support: Our professional service team promptly resolves any issues, ensuring peace of mind.

- Excellent Reputation: Positive feedback from global customers proves the reliability and consistent quality of our anodized aluminum sheets.

Other Forms & Profiles of Anodized Aluminum

- anodized aluminum foil

- anodized aluminum coil

- anodized aluminum rods

- anodized aluminum tubes

- anodized aluminum panels / wall panels

- anodized aluminum angle

- black anodized aluminum angle

- anodized aluminum channel

- anodized aluminum extrusion

- anodized aluminum profile

- anodised aluminium cladding

- anodized aluminum c channel

- anodized aluminum l bracket