The reflector aluminum sheet is a type of aluminum alloy sheet processed through special techniques, giving its surface high reflectivity. With the rapid development of modern industry and the construction sector, the demand for efficient reflective materials is increasing. Relying on its excellent optical performance, mechanical properties, and environmental adaptability, the reflector aluminum sheet shows broad application prospects in lighting systems, solar energy utilization, and architectural decoration.

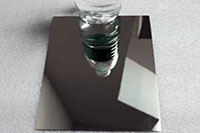

Reflective aluminum mirror sheet is a type of aluminum alloy material with high reflective performance. Its surface is highly polished, and the reflectivity can typically reach over 85%. The core characteristic of the aluminium reflector sheet is its optical reflection effect, making it widely used in the lighting and decoration industries.

Features of Aluminium Reflector Sheet

- High reflectivity: This is its most essential characteristic. High-quality reflector aluminum sheets can reach a reflectivity of 80%–95% within the visible spectrum, and they also have high reflectivity for infrared rays.

- Lightweight: Due to aluminum’s low density, reflector aluminum sheets are very light, making them easy to transport, install, and use in structural designs.

- Excellent weather resistance: With anodizing or coating treatments, a dense protective layer is formed on the surface, effectively resisting UV rays, humidity, acids, alkalis, and pollutants, thereby providing long service life.

- Good processability: Aluminum materials are easy to cut, bend, and stamp, allowing processing into various complex shapes and curves to meet different design needs.

- Good thermal stability: Able to maintain its shape and reflective performance without deformation across a wide temperature range.

Reflectivity Grades of Aluminium Reflector Sheet

- Standard reflectivity: 86% (e.g., 1050/1070 pure aluminum sheet)

- High reflectivity: 95%–98%

- Super mirror treatment: Some products achieve more stable reflectivity through polishing or pre-anodizing processes

| Reflectivity Grade | Reflectivity Range | Application Field |

| Standard reflective grade | 75%–85% | General lighting or decorative fields |

| Standard mirror grade | 86%–90% | General lighting reflectors, indoor architectural decoration |

| High mirror grade | 91%–95% | High-power LED lighting, solar thermal reflection materials |

| Super mirror grade | Above 96% | Optical instruments, laser reflectors, high-precision solar power systems |

Different reflectivity grades of aluminum sheets differ significantly in terms of surface processing methods, reflectivity stability, mechanical properties, and cost.

Material of Reflective Aluminum Mirror Sheet

The material of reflective aluminum mirror sheets is mainly used in scenarios requiring high light reflection, such as lighting reflectors, solar collectors, architectural decoration, and electronic product enclosures. Based on usage and performance requirements, the commonly used materials are divided into two categories: high-purity aluminum and aluminum alloys.

1xxx Series Pure Aluminum

- Main composition: Aluminum content ≥ 99.00%

- Features: High purity, excellent conductivity, thermal conductivity, and reflectivity; good workability but relatively low strength.

- Applications: Ideal material for manufacturing high-reflectivity mirror aluminum sheets.

3xxx Series Aluminum-Manganese Alloy

- Main composition: Manganese as the primary alloying element, content between 1.0–1.5%.

- Features: Good corrosion resistance, formability, and weldability, with higher strength than pure aluminum.

- Applications: Architectural decoration, lighting equipment, etc.

5xxx Series Aluminum-Magnesium Alloy

- Main composition: Magnesium as the main alloying element, content between 3–5%.

- Features: Low density, high tensile strength, high elongation, good corrosion resistance.

- Applications: Solar energy and high-power LED lighting fields.

1060 1070 Aluminium Reflector Sheet

The commonly used high-purity aluminum materials are 1060 and 1070 series. These aluminum materials have high purity (generally above 99.6%) and excellent conductivity and reflectivity.

Characteristics of 1060 1070 Aluminium Reflector Sheet

- Strong reflectivity: The mirror effect is excellent, capable of reflecting a large amount of light, suitable for high-demand reflection scenarios.

- Soft texture: Due to the high purity of aluminum, the material has relatively low hardness but good ductility, making it easy to process into complex shapes.

- Lightweight: The low density makes it ideal for applications requiring lightweight materials.

3003 Aluminium Reflector Sheet

3003 aluminum alloy adds manganese to pure aluminum, with a content of about 1.0%-1.5%. The addition of manganese improves the strength and corrosion resistance of aluminum, making the 3003 aluminum alloy retain certain reflectivity while having better mechanical properties.

Characteristics of 3003 Aluminium Reflector Sheet

- Strong corrosion resistance: Suitable for humid, corrosive environments, extending the material's service life.

- Higher strength: Compared to 1060 and 1070 pure aluminum, the 3003 aluminum alloy has higher strength, suitable for structural components that require certain strength.

- Good reflectivity: Although slightly lower than high-purity aluminum, the 3003 aluminum alloy still meets most reflection needs.

The 1060 and 1070 series aluminum materials are more suitable for scenarios requiring high reflectivity and lightweight, while the 3003 aluminum alloy is ideal for applications needing stronger corrosion resistance and mechanical strength.

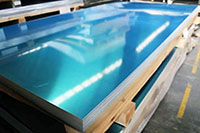

Specifications of Aluminium Reflector Sheet

| Alloy | 1050 1060 1070 1085 5052 5083 |

| Width | 50-1500MM |

| Thickness | 0.1-6 |

Thickness Specifications

The thickness of reflector aluminum sheets varies based on application scenarios and performance requirements, with multiple specifications available:

| Type | Thickness Range | Application Field |

| Ultra-thin sheet | 0.15–0.5mm | Lighting reflectors, small decorative parts |

| Thin sheet | 0.5–2.0mm | Lighting, decoration, electronic product casings |

| Medium sheet | 2.0–6.0mm | Building curtain walls, furniture panels |

| Thick sheet | Above 6.0mm | Structural components or special applications |

Width and Length Specifications

The width and length of reflector aluminum sheets are usually determined based on production processes and actual application needs. Common standard widths include 1000mm, 1220mm, 1250mm, and 1500mm, while standard lengths include 2000mm, 2440mm, 2500mm, 3000mm, and 6000mm.

Dimensional Tolerance Requirements

High-quality reflector aluminum sheets typically have strict dimensional tolerance requirements to ensure consistency and interchangeability.

Specification Selection for Different Application Scenarios

Different application scenarios require different specifications of reflector aluminum sheets. For example, lighting fixtures typically use 0.3–1.0mm thick sheets with a width of 1250mm in coil or sheet form; solar collectors typically use 0.5–1.5mm thick sheets with a width of 1250mm.

-

1050 Aluminium reflector sheet coil

1050 Aluminium reflector sheet coil is a type of mirror-finished aluminum coil made from 1050 aluminum alloy.

-

1060 Aluminium reflector sheet coil

The 1060 Aluminium reflector sheet coil refers to aluminum material with a 1060 alloy that has undergone special polishing and oxidation treatments, resulting in a high gloss finish and the ability to reflect light, similar to a mirror.

-

1070 Aluminium reflector sheet coil

1070 aluminum mirror coil is a type of high-purity aluminum alloy coil with an aluminum content of up to 99.7%. Due to its high purity and smooth surface treatment, the 1070 aluminum mirror coil has an extremely high reflectivity, making it suitable for use as a light-reflecting material.

-

1085 Aluminium reflector sheet coil

1085 aluminum mirror sheet is commonly used as a raw material for anodized mirror aluminum plates or coils. With a purity of up to 99.85%, 1085 aluminum boasts excellent reflectivity and a high degree of smoothness.

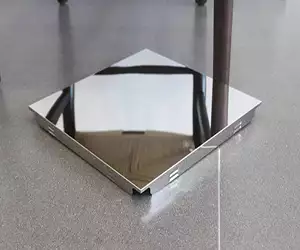

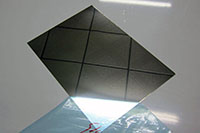

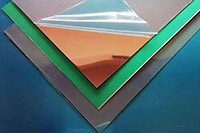

Surface Treatment Methods of Reflector Aluminum Sheets

Aluminum mirror reflector sheets use high-purity aluminum and undergo precision rolling and polishing processes, resulting in a high-reflectivity mirror effect. Their reflectivity can reach 85%–95%, with uniform light reflection, strong resistance to discoloration and oxidation, along with advantages of lightweight, strong corrosion resistance, and easy processing.

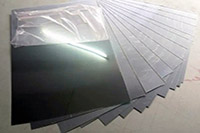

Coated Reflective Aluminum Sheets

Coating treatment involves applying one or more layers of organic or inorganic materials on the aluminum sheet surface to enhance reflectivity and protective performance. Types include organic coatings, inorganic coatings, and composite coatings.

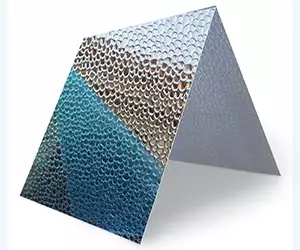

Embossed Reflective Aluminum Sheets

Embossed reflective aluminum sheets are produced by forming regular or special patterns on the aluminum surface through mechanical embossing or roller pressing. They are widely used in lamp reflectors, interior and exterior building decoration, billboards, vehicle decoration, and household appliance exteriors, combining both functionality and aesthetics.

Special Surface Treatments

In addition to the main treatment methods above, there are also special surface treatments such as brushing, sandblasting, and nano-coating, which can endow reflector aluminum sheets with unique properties and appearances.

Mirror-anodized aluminum sheets, with their permanent reflectivity, outstanding durability, and clear imaging effects, are positioned in the high-end market; coated reflector aluminum sheets, with more color options and competitive prices, meet specific decorative and functional demands. When choosing, one should comprehensively consider the application scenario, performance requirements, and budget.

Applications of Aluminium Reflector Sheet

Solar Energy Field

- Used as solar collector reflectors, requiring corrosion resistance and reflectivity ≥ 86%

- Common materials: 1060/3003 mirror aluminum sheets, thickness 0.3–1.0mm

Lighting Equipment

Lamp reflectors, UV lamp covers, requiring reflectivity ≥ 95% with heat dissipation performance

Typical product: Mirror aluminum sheet (reflectivity 98%)

Architectural Decoration

- Exterior wall decoration, indoor ceilings, enhanced weather resistance through oxidation treatment

- Customizable colors (e.g., titanium gold, rose gold)

Selection Recommendations for Reflector Aluminum Sheets

Selection Based on Application Environment

The application environment is an important factor when selecting reflector aluminum sheets. For example, indoor environments may use pure aluminum such as 1060, 1070, or alloys like 3003; for outdoor environments, aluminum-magnesium alloys such as 5052 and 5083 are recommended.

Selection Based on Performance Requirements

Different performance requirements lead to different choices of reflector aluminum sheets. For high reflectivity requirements, high-purity aluminum such as 1085 or alloys like 5052 can be chosen; for high mechanical strength, aluminum-magnesium alloys such as 5052 and 5083 are suitable.

Selection Based on Application Fields

Different application fields have varying requirements for reflector aluminum sheets. The lighting industry usually selects pure aluminum such as 1060, 1070, or alloys like 3003; the solar energy utilization field usually selects alloys such as 3003 and 5052.

Selection Based on Budget and Cost

Reflector aluminum sheet selection also depends on budget and cost considerations. For limited budgets, standard reflective or standard mirror-grade products are suitable; for medium budgets, high mirror-grade products can be chosen; for high budgets, super mirror-grade products are recommended.

By comprehensively considering application environment, performance requirements, and cost factors, different solutions such as economic choice, cost-performance choice, high-performance choice, high-end choice, and special environment choice can be proposed.

Haomei Provides Reflective Aluminum Mirror Sheets

Reflective aluminum mirror sheets can be cut, formed, and surface treated, such as coating, anodizing, etc., according to customer requirements. Additionally, their easy-to-process properties make them suitable for scenarios requiring complex shapes and custom designs.

Haomei Aluminum offers high-quality alloy bright anodized aluminum reflector sheets with various decorative effects, suitable for all industrial lighting products, interior decoration, and innovative design light reflectors. We also provide aluminum reflector sheets of various widths, lengths, and specifications to meet the needs of different industrial fields.

-

468mm x 48mm x 2mm aluminium reflector sheet

-

438mm x 48mm x 3mm aluminium reflector sheet

-

549mm x 40mm x 3mm aluminium reflector sheet

-

1000mm x 500mm x 0.5mm aluminium reflector sheet

-

205mm x 48mm x 2mm aluminium reflector sheet

-

250mm x 250mm x 0.5mm aluminium reflector sheet

-

273mm x 40mm x 3mm aluminium reflector sheet

-

150mm x 100mmx 2mm aluminium reflector sheet

-

500mm x 250mm x 0.8mm aluminium reflector sheet

-

198mm x 39mm x 3mm aluminium reflector sheet

-

338mm X 48mm x 3mm aluminium reflector sheet

-

150mm x 47mm x 2mm aluminium reflector sheet

-

538mm x 48mm x 3mm aluminium reflector sheet

-

508mm x 48mm x 3mm aluminium reflector sheet

-

568mm x 48mmx 2mm aluminium reflector sheet

-

488mm x 48mm x 2mm aluminium reflector sheet

-

368mm x 48mm x 2mm aluminium reflector sheet

-

400mm x 69mm x 0.45mm aluminium reflector sheet

-

580mm x 48mm x 3mm aluminium reflector sheet

-

418mm x 48mm x 2mm aluminium reflector sheet

-

388mm x 48mm x 3mm aluminium reflector sheet

-

228mm x 62mm x 2mm aluminium reflector sheet

-

529mm x 40mm x 3mm aluminium reflector sheet

-

538mm x 48mm x 2mm aluminium reflector sheet

-

205mm x 48mm x 3mm aluminium reflector sheet

-

205mm x 48mm x 2mm aluminium reflector sheet

Reflective aluminum mirror sheets, with their high light reflection efficiency and excellent physical properties, are widely used in industries such as lighting and decoration, especially for products and occasions pursuing high efficiency and aesthetic design.