What is Corrugated Aluminum?

Corrugated aluminum sheet, also known as aluminum tile, corrugated aluminum sheet, profiled aluminum sheet or corrugated aluminum alloy sheet, is a type of profiled sheet made by processing aluminum sheet into various waveforms through roll forming and cold bending technology. This unique corrugated structure provides the aluminum sheet with higher strength and rigidity while maintaining the lightweight characteristics of aluminum, making it an ideal material for construction, industrial, and decorative applications.

Corrugated aluminum sheet is a type of aluminum sheet that, after roll forming, is used for roofing, fencing, and wall cladding. Corrugated aluminum wall panels and roofing sheets are lightweight and corrosion-resistant. In areas with heavy rainfall or coastal regions, aluminum is a better choice compared to metal. The main drawback of corrugated aluminum is its high cost. Aluminum is 20–30% more expensive than corrugated metal.

Characteristics of Corrugated Aluminum Sheet

The main feature of corrugated aluminum sheet is the alternating ridge and trough structure formed through the roll forming process. This corrugated structure greatly improves the strength-to-weight ratio of the material, making it particularly suitable for applications requiring high resilience and lightweight properties.

- Lightweight and High Strength: Its special wave shape increases the strength of the sheet while ensuring it remains lightweight, making the overall structure more stable.

- Excellent Weather Resistance: The surface can be treated with fluorocarbon coating or anodizing, with long-lasting color (saturation above 95% even after 5 years), suitable for outdoor use.

- Versatility: With sound insulation, heat insulation, and anti-slip properties, it is suitable for roofing, exterior walls, shopfronts, and other applications.

- Fire Resistance: Corrugated aluminum sheet has fire-resistant properties.

- Easy Processing: Corrugated aluminum sheet is easy to process, suitable for machining, forming, welding, and other subsequent processes.

- Sustainability: Aluminum is recyclable, and some manufacturers also offer low-carbon aluminum products produced with recycled materials and renewable energy.

Corrugated Aluminum Roofing Specifications

| Alloy | 1050 1060 1100 3003 5005 5052 |

| Temper | O, H12, H22, H14, H24, H16, H26, H18, H32 |

| Thickness | 0.2-6.0mm |

| Width | 200-2650mm |

| Length | 1-10mm |

| Wave height | 17-18 mm |

| Coating | Galvanized, color coated(Charcoal Gray/Dark Bronze/Matte Black/Regal White/Almond), Mill Finish |

| Standard | GB/T 3880-2005, B209-2020, JC/T 1074-2012, ASTM A1196-2020, ISO 9001, CE, SGS |

| Remark | Specifications can be customized |

- Thickness: 0.2–6.0mm (for construction typically 0.3–2.5mm)

- Wave Types: 7/8 inch, 2.5 inch, 4 inch, and other rib heights, designed to meet different stiffness requirements. For example, 4-inch rib pitch sheets are suitable for industrial roofs requiring higher stiffness.

- Standards: Complies with ASTM B209, GB/T 3880, and other international standards, with some products certified to ISO 9001 and ISO 14001.

Thickness Specifications

- General Thickness: commonly 0.3mm to 3.0mm.

- Roofing Thickness: typically 0.5mm to 1.5mm for roofing applications.

- Wall Cladding Thickness: usually 0.4mm to 1.2mm for wall decoration.

- Special Application Thickness: 1.5mm to 3.0mm thick sheets for special requirements.

Width and Length Specifications

- Standard Width: typically 1000mm to 1220mm.

- Effective Coverage Width: commonly available in 750mm, 825mm, 836mm, 840mm, 850mm, and 900mm specifications.

- Length: customizable according to customer needs, typically between 800mm and 6000mm.

Corrugation Shape and Size Specifications

- Wave Height: commonly 15mm, 18mm, 23mm, 25mm, 35mm.

- Wave Pitch: commonly 76mm, 125mm, 210mm, 225mm.

Common Tile Types

| Tile Type | Wave Height | Wave Pitch | Effective Width | Application Scenarios |

| Type 750 | 35mm | 125mm | 750mm | Insulation projects in power plants and chemical plants |

| Type 840 | 23mm | 210mm | 840mm | Industrial insulation |

| Type 836 | 18mm | 76mm | 836mm | Popular corrugated type, good drainage effect |

| Type 900 | 15mm | 225mm | 900mm | Side wall decoration |

Haomei Corrugated Aluminum Sheet Popular Sizes

-

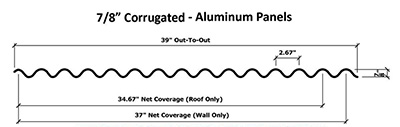

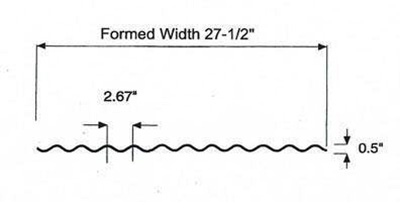

7/8" Corrugated Aluminum Sheet

The 7/8-inch corrugated aluminum sheet commonly comes in thicknesses of .032 and .040, with a minimum roof slope of 3/12.

Rib Height: 7/8"Rib Distance (Pitch): 2.67"

-

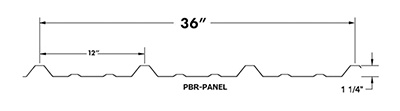

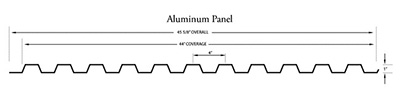

PBR Aluminum Wall Panels

PBR aluminum wall panels are typically available in thicknesses of .032 and .040, with a minimum roof slope of 3/12.

Rib Height: 1.25 inchesRib Distance (Pitch): 12"

-

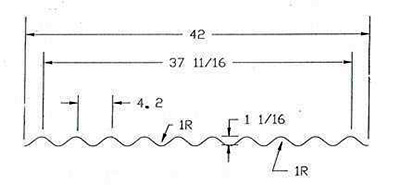

4.2 Inch Corrugated Aluminum Sheet

The 4.2-inch corrugated aluminum sheet is commonly made from 3003 aluminum alloy, offering corrosion resistance.

Rib Height: 1/16"Rib Distance (Pitch): 4.2"

-

2.5" x 0.5" Corrugated Aluminum Panel

The 2.5" x 0.5" corrugated aluminum panel is commonly used for roofing, siding, and industrial applications where durability and load-bearing capacity are important.

Rib Height: 1/2"Rib Distance (Pitch): 2.67"

-

1.25 inch x 0.25 inch Corrugated Aluminum Panel

Compared to the 2.5-inch rib profile, this shallower rib profile offers less structural support, making it suitable for areas with lower structural demands.

Rib Height: 1/4"Rib Distance (Pitch): 1 1/4"

-

Ultra-Rib Painted White Corrugated Aluminum Sheet

Ultra-Rib painted white corrugated aluminum sheet features an enhanced ribbed or ridged design to provide extra strength and rigidity. Compared to standard corrugated sheets, the "Ultra-Rib" profile typically has deeper and more pronounced ribs.

-

Aluminum Stucco Embossed Mill Finish 4" Rib

The Aluminum Stucco Embossed Mill Finish with a 4" rib has rib spacing of 4 inches. Compared to the 8-inch rib profile, it offers a more compact rib pattern. This design improves the stiffness and load-bearing capacity of the panel while maintaining a more streamlined appearance.

Rib Height: 1"Rib Distance (Pitch): 4"

-

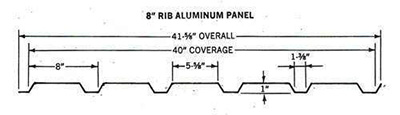

Aluminum Stucco Embossed Mill Finish (8" Rib)

The Aluminum Stucco Embossed Mill Finish (8" Rib) has ribs spaced 8 inches apart, offering a more pronounced rib pattern compared to shallower profiles. This design enhances the structural strength and stiffness of the panel.

Rib Height: 1"Rib Distance (Pitch): 8"

-

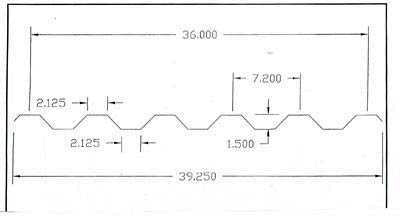

7.2 Corrugated Aluminum Sheet

The 7.2 Corrugated Aluminum Sheet has a rib spacing of 7.2 inches, creating a deeper rib pattern compared to shallower profiles. This deeper corrugation improves the sheet’s structural strength and stiffness.

Rib Height: 1.5"Rib Distance (Pitch): 7.2"

-

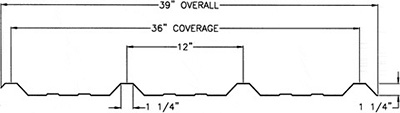

12" rib (R Panel) Corrugated Aluminum Sheet

The 12-inch Rib (R Panel) Corrugated Aluminum Sheet features a series of wide, shallow ribs (typically spaced 12 inches apart). This panel design is highly suitable for both commercial and residential buildings, offering excellent strength and weather resistance.

Rib Height: 1 1/4"Rib Distance (Pitch): 12"

Corrugated Aluminum Sheet Alloys

Corrugated aluminum sheets are mainly made of aluminum alloys such as 1060, 1100, 3003, and 5083, among which the 3003 alloy, due to the addition of manganese, has stronger corrosion resistance, suitable for high acid-alkali or coastal environments. The corrugated design is formed through the roll forming process into parallel ridges and troughs, significantly improving the strength-to-weight ratio of the material. For example, sheets with a wave height of 17–18mm can withstand higher loads.

1000 Series Pure Aluminum

Such as 1050, 1060, and 1100. These pure aluminums have excellent corrosion resistance and good electrical conductivity, with outstanding processing performance, but relatively low strength. 1060 aluminum alloy is the most commonly used pure aluminum material, with aluminum content above 99.6%, featuring excellent corrosion resistance and formability.

3000 Series Aluminum Alloys

Such as 3003 and 3004. The 3003 alloy, with added manganese, significantly improves the material’s strength and corrosion resistance while maintaining good processing performance. The 3004 alloy, with added magnesium, further enhances strength and toughness, making it especially suitable for applications requiring higher strength.

5000 Series Aluminum Alloys

Such as 5052. This type of alloy, with added magnesium, offers higher strength and excellent resistance to marine corrosion, though it is relatively less used in corrugated aluminum sheets.

3003 Corrugated Aluminum Sheet

Characteristics: 3003 offers good corrosion resistance and workability with moderate strength.

Applications: Commonly used for corrugated aluminum sheets requiring corrosion resistance and good formability, such as in building and roofing materials.

5052 Corrugated Aluminum Sheet

Characteristics: 5052 provides higher strength and excellent corrosion resistance, especially in marine environments.

Applications: Commonly used for corrugated aluminum sheets in applications requiring higher strength and corrosion resistance, such as boats and industrial equipment.

1100 Corrugated Aluminum Sheet

Characteristics: 1100 has lower strength but excellent corrosion resistance and workability.

Applications: Primarily used in applications requiring good corrosion resistance and workability but not high strength for corrugated aluminum sheets.

- 3003 Corrugated Aluminum Sheet

- 1100 Corrugated Aluminum Sheet

- 3004 Corrugated Aluminum Plate

- 3104 Corrugated Aluminum Sheet

- 3105 Corrugated Aluminum Sheet

Impact of Alloy Composition on Performance

Different alloy compositions significantly affect the performance of corrugated aluminum sheets: corrosion resistance, strength and hardness, processing performance, and heat resistance all vary depending on the alloying elements. Choosing the right alloy material is key to ensuring that corrugated aluminum sheets perform well in specific applications.

Surface Treatments of Corrugated Aluminum Sheet

Common surface treatments include anodizing, fluorocarbon coating (such as charcoal gray, matte black), and pre-roll coating. Among them, fluorocarbon coating can resist acid rain and UV erosion, with salt spray test duration over 3000 hours and service life of more than 25 years. Some high-end products use micro-arc oxidation technology to further enhance wear resistance and insulation performance.

Anodizing Treatment

Forms a dense oxide film on the surface of the aluminum sheet through an electrolytic oxidation reaction, giving it high hardness and wear resistance, and significantly improving corrosion resistance.

- Excellent corrosion, wear, and weather resistance

- Good insulation and thermal stability

- Capable of forming oxide films of different thicknesses and colors

Fluorocarbon Coating Treatment

Uses polyvinylidene fluoride resin (PVDF) as the main film-forming material to create a high-performance coating.

- Excellent corrosion resistance and weather resistance

- Resistant to acid rain, salt spray, and various air pollutants

- Long service life, ensuring no fading for over 25 years

Electrophoretic Coating Treatment

A coating method that applies paint uniformly onto the aluminum surface through an electric field, forming an even coating.

- Uniform coating, strong adhesion, high production efficiency

- High paint utilization, low environmental pollution

- Widely used in interior decoration and high corrosion-resistant applications

Powder Coating Treatment

A coating method where powder paint is electrostatically sprayed onto the aluminum surface, forming a smooth and attractive coating.

- Beautiful coating appearance, good weather resistance, wide color options

- High hardness, good wear resistance, resistant to scratches and impacts

- Typical coating thickness between 60–100 microns

-

Anodized corrugated aluminum sheet

An anodized corrugated aluminum sheet is an aluminum material whose surface is treated through an electrochemical oxidation process to form a hard oxide layer. This treatment not only enhances the corrosion resistance and wear resistance of the aluminum sheet but also improves its decorative effect, giving it a uniform gloss or a variety of color options. The corrugated design increases the strength and rigidity of the sheet while maintaining lightweight characteristics, making it ideal for industrial building facades, roofs, warehouses, or interior decoration, where durable, aesthetically pleasing, and lightweight materials are required.

-

Coated aluminium roofing sheet

A coated aluminum roofing sheet is a roofing material in which a weather-resistant coating is applied on the aluminum substrate. It typically features corrosion resistance, UV protection, and fade resistance. The coating not only extends the service life of the roof but also provides a wide range of color and texture options to meet aesthetic requirements in architecture. These aluminum roofing sheets are lightweight and easy to install, commonly used in industrial plants, warehouse buildings, commercial buildings, and residential roofs, combining practicality with decorative appeal.

Other Surface Treatment Methods

In addition to the above main surface treatments, corrugated aluminum sheets can also be processed with wood grain transfer, stone grain finish, brushed finish, and anodized plating, offering more possibilities for decoration.

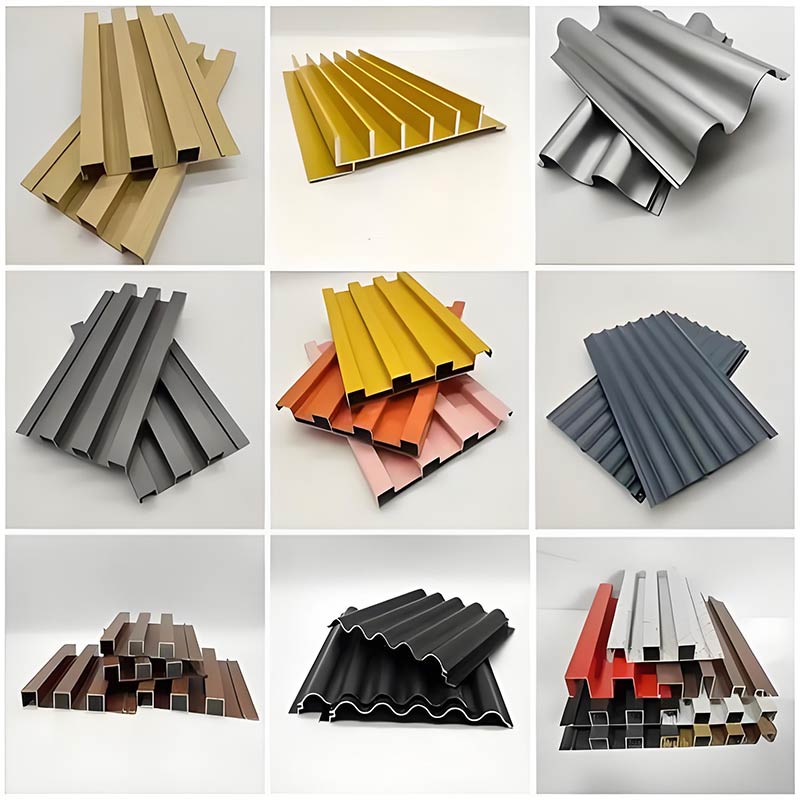

Corrugated Aluminum Sheet Color Options

After surface treatment, corrugated aluminum sheets can present a wide variety of colors to meet different design needs:

Basic Color Series

- White series: pure white, ivory white, silver white, gray white, etc.

- Gray series: light gray, medium gray, dark gray, silver gray, graphite gray, etc.

- Black series: pure black, dark gray-black, matte black, etc.

Metallic Texture Color Series

- Gold series: golden yellow, light gold, champagne gold, rose gold, titanium gold, etc.

- Silver series: bright silver, matte silver, stainless steel color, etc.

- Bronze series: antique bronze, bronze, red copper, etc.

Colorful Series

- Blue series: dark blue, light blue, sky blue, ocean blue, porcelain blue, etc.

- Red series: dark red, light red, brick red, wine red, maroon, etc.

- Green series: dark green, light green, emerald green, grass green, etc.

- Yellow series: golden yellow, light yellow, lemon yellow, etc.

Special Effect Color Series

- Wood grain effect: oak grain, walnut grain, teak grain, etc.

- Stone grain effect: marble grain, granite grain, etc.

- Pearlescent effect: pearl-like luster and color variations

- Fluorescent effect: emits fluorescence under natural light or ultraviolet light

Factors Affecting Color Selection

When choosing the color of corrugated aluminum sheets, factors such as architectural style, usage environment, durability requirements, and personal preferences need to be considered to create a satisfying visual effect.

Our standard Polyvinylidene Fluoride (PVDF) has excellent chemical composition, which gives it high mechanical strength and outstanding wear resistance. This tough engineering thermoplastic has superior durability and excellent chemical resistance, capable of withstanding halogens and acids that may cause degradation. The surface of PVDF panels can endure high temperatures and strong ultraviolet exposure, while providing longer-lasting resistance to fading and chalking compared to SMP-coated panels.

By using aluminum roofing and wall panels with PVDF coatings, you will obtain painted aluminum sheets that are more durable, vibrant, and aesthetically pleasing than any other coating system.

- Mill Finish Corrugated Aluminum Sheet

- Matte Black Corrugated Aluminum Sheet

- Dark Bronze Corrugated Aluminum Sheet

- Charcoal Gray Corrugated Aluminum Sheet

- Sierra Tan Corrugated Aluminum Sheet

- Almond Corrugated Aluminum Sheet

- Regal White Corrugated Aluminum Sheet

- Fresh Rust Corrugated Aluminum Sheet

Chemical composition of 1050 1060 1100 aluminum corrugated sheets

| Alloy | 1050 | 1060 | 1100 |

| Al | 99.5% | 99.6% | 90.00% |

| Si | ≤0.25% | ≤0.25% | - |

| Fe | ≤0.40% | ≤0.35% | - |

| Cu | ≤0.06% | ≤0.06% | ≤0.20% |

| Mn | ≤0.05% | ≤0.03% | ≤0.05% |

| Ti | ≤0.03% | ≤0.03% | - |

| V | ≤0.06% | ≤0.06% | - |

| Si+Fe | - | - | ≤0.95% |

Common Types and Advantages of Corrugated Aluminum Sheets

General Type Corrugated Aluminum Sheet

- Characteristics: Basic product type, high strength, strong corrosion resistance, suitable for building roofs, walls, and general decoration.

- Specifications: Thickness 0.5-2.0mm, corrugation height 10-50mm, length 1-12m.

Anti-Corrosion Type Corrugated Aluminum Sheet

- Characteristics: Surface treated with special anti-corrosion methods (such as fluorocarbon spraying, anodizing), suitable for marine, chemical, and other corrosive environments.

- Specifications: Thickness 0.8-2.5mm, corrugation height 15-60mm.

PVDF-coated corrugated aluminum sheet

PVDF is a tough engineering thermoplastic, and PVDF coatings offer significantly greater durability, allowing colors to remain vibrant and surfaces smooth over time. The PVDF coating also effectively resists high temperatures and long-term UV exposure, preventing fading and chalking of the aluminum sheet.

For construction projects seeking long-term stability and low maintenance, PVDF-coated corrugated aluminum sheets are undoubtedly the best choice.

Corrugated Aluminum Composite Sheets

Corrugated aluminum composite sheets are lightweight, durable, and highly corrosion-resistant, making them ideal for a variety of building and construction applications. These sheets consist of a corrugated aluminum core sandwiched between two layers of aluminum or composite material, offering excellent strength and stiffness while maintaining a lightweight structure. The corrugated design enhances structural integrity, making them perfect for roofing, cladding, and other external or internal uses.

Perforated Corrugated Aluminum Panels

Perforated corrugated aluminum panels combine the structural strength of corrugated sheets with ventilation or acoustic properties, making them ideal for façades, sunshades, and industrial applications where airflow, light filtration, or sound absorption is needed.

Aluminium Ibr Roof Sheeting

Aluminium IBR (Inverted Box Rib) roof sheeting is a durable, lightweight roofing solution commonly used in industrial, commercial, and agricultural buildings, offering excellent corrosion resistance, high strength, and ease of installation.

Galvanized Aluminium Roofing Sheets

Galvanized aluminium roofing sheets are coated with a zinc layer to enhance corrosion resistance, offering long-lasting protection, lightweight construction, and high durability for residential, commercial, and industrial roofing applications.

Corrugated Aluminium Sheet Cladding

Corrugated aluminium sheet cladding provides a protective and decorative exterior layer for walls and façades, combining weather resistance, durability, and a visually appealing corrugated texture suitable for both industrial and modern architectural designs.

Insulated Corrugated Aluminum Sheet

- Characteristics: Filled with insulation materials (such as rock wool, polyurethane) inside, offering thermal insulation and heat resistance, widely used in building exteriors and cold storage facilities.

- Specifications: Thickness 1.0-3.0mm, corrugation height 20-80mm.

Aluminum Corrugated Core Composite Panel

- Characteristics: Consists of two aluminum sheets with a corrugated core in between, featuring lightweight, high rigidity, fire resistance (A2 grade), and environmental protection, suitable for high-demand applications such as external walls and ceilings.

- Specifications: Total thickness 4mm, width 1220-1500mm, length up to 4000mm.

Brushed Aluminum Corrugated

Brushed aluminum corrugated sheets have a sleek, modern aesthetic with a textured metallic finish. The brushed surface adds a refined look to the natural strength and durability of aluminum, making it ideal for decorative cladding, interior design, and architectural elements. These corrugated sheets not only look stylish but also offer excellent rust, corrosion, and weather resistance.

Advantages of Corrugated Aluminum Sheet

- Lightweight: The density of aluminum is 2.73g/m³, only 1/3 that of steel, greatly reducing the overall weight of building structures.

- High strength: Through alloy composition, processing, and heat treatment methods, very high strength can be achieved, allowing it to withstand large loads.

- Corrosion resistance: Aluminum has a self-rusting resistance ability. The oxide layer formed on the surface prevents further oxidation and rust, with good acid and alkali resistance.

- Diverse surface treatments: Various surface treatments can be applied, such as anodizing, electrophoresis, chemical treatment, polishing, and painting, to meet different decorative and functional requirements.

- Good plasticity: Easy to process and form, it can be made into various shapes and sizes according to design requirements.

- Environmental performance: Recyclable and reusable, in line with the concept of sustainable development.

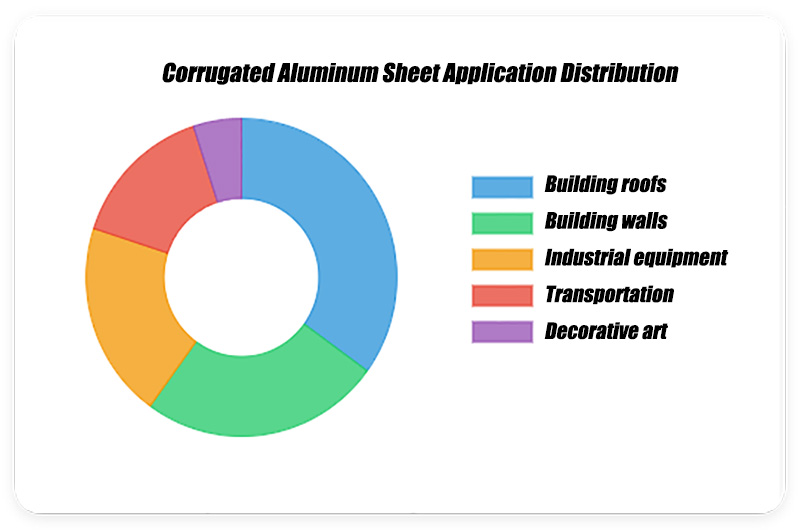

Applications of Corrugated Aluminum Sheet

- Building roofing: Replaces traditional iron sheets, such as aluminum-magnesium-manganese roofing tiles (3003 grade), rust-resistant and long-lasting.

- Commercial facades: Modular installation is convenient, and combined with LED light strips can enhance the visual effect (e.g., a case where customer flow increased by 40%).

- Industrial maintenance: Used in factory buildings, cold storage floors, etc., such as five-bar tread aluminum plates to enhance slip resistance.

- Decoration and infrastructure: Through different color coatings and texture designs, it can be used in interior ceilings, ventilation ducts, and municipal landscape projects.

Applications in Building Roofing

- Industrial plants

- Large public buildings

- Commercial buildings

- Residential buildings

Due to its lightweight and high strength, good waterproof performance, and convenient installation, corrugated aluminum sheet has become an ideal material for roofing systems.

Applications in Building Walls

- Building curtain walls

- Exterior wall decoration

- Interior wall partitions

- Ceiling decoration

As a wall material, corrugated aluminum sheet offers a unique appearance effect and excellent performance.

Applications in Industrial Equipment and Pipelines

- Equipment protection

- Pipeline insulation

- Chimneys and flues

- Ventilation systems

Corrugated aluminum sheet has wide applications in the protection and decoration of industrial equipment and pipelines.

Applications in the Transportation Sector

- Vehicle interiors

- Marine applications

- Transportation facilities

- Advertising and signage

The use of corrugated aluminum sheet in the transportation sector is also becoming increasingly common.

Applications in Decoration and Art

- Interior decoration: Widely used in interior decoration of hotels, restaurants, exhibition halls, and other venues.

- Art installations: Becoming an ideal material for artists and designers to create art installations.

- Furniture and household items: Increasingly used in the design of tables, chairs, screens, lamps, and other items.

- Landscape design: Used to create sculptures, landscape walls, flower boxes, and other facilities.

| Application Field | Specific Application Scenarios | Core Advantages |

| Architectural Decoration (Interior & Exterior) | Building exterior curtain walls, roofing, wall panels, ceilings, interior decorative partitions, suspended ceilings | Strong decorative effect, waterproof, corrosion-resistant, lightweight reduces building load |

| Transportation | High-speed rail/metro carriage interiors, truck bodies, partial aircraft components | Lightweight (energy-saving), high strength, good weather resistance |

| Industry and Packaging | Container housing, equipment protective covers, display stands, truck fuel tanks | Durable and strong, high plasticity, low maintenance cost |

| Other Fields | New energy batteries, 3C products, and semiconductor equipment | Meets specific industrial requirements |

Typical Application Fields

| Application Scenario | Specific Use | Applicable Type |

| Construction Field | Industrial and civil building roofs, exterior walls, interior wall decoration; steel structure workshops, warehouse enclosure structures | Standard Type, Insulated Type, Composite Type |

| Transportation Facilities | Tunnel linings, sound barriers, station canopies | Anti-corrosion Type, Standard Type |

| Decorative Projects | Ceilings, background walls, special-shaped artistic installations | Corrugated Aluminum Plate, Composite Type |

| Special Environments | Chemical plants, offshore platforms, cold storage | Anti-corrosion Type, Insulated Type |

Specification Parameters Reference

| Type | Thickness Range (mm) | Corrugation Height (mm) | Length Range (m) | Width Range (m) |

| Standard Type | 0.5-2.0 | 10-50 | 1-12 | 0.5-2.0 |

| Anti-corrosion Type | 0.8-2.5 | 15-60 | 1-12 | 0.8-2.5 |

| Insulated Type | 1.0-3.0 | 20-80 | 1-12 | 0.8-2.5 |

| Composite Type (Core Panel) | 4.0 (Total Thickness) | Not Applicable | ≤4.0 | 1.22-1.5 |

Corrugated Aluminum Sheet Advantages Over Other Materials

- Cost-effective: More economical than stainless steel or iron, with lower maintenance costs.

- Environmentally Friendly: Fully recyclable, and its reflective surface saves energy by reducing cooling costs.

- Flexible Installation: Can be installed on slopes as low as 3:12 and can adapt to curved surfaces.

- Aesthetic Appeal: Offers more than 40 colors and textures (such as brushed and stucco embossed) to meet various design needs.

Corrugated Aluminum Sheet Manufacturing Process Includes

- Material Preparation: After aluminum coils are unrolled, they are fed into rolling molds to form corrugations.

- Surface Treatment: Optional treatments include anodizing, powder coating, or rolled surface finishes to enhance appearance and corrosion resistance.

Corrugated aluminum sheets combine functionality and aesthetics, making them a top choice for various industries and construction projects.

Selection and Usage Guide for Corrugated Aluminum Sheet

Select the Right Alloy Material

- Choose according to the usage environment

- Choose according to strength requirements

- Choose according to processing requirements

Determine Suitable Specifications and Sizes

- Determine thickness based on load requirements

- Determine corrugation shape based on architectural design

- Determine length based on transportation and installation conditions

Select the Appropriate Surface Treatment Method

- Choose according to usage environment

- Choose according to decorative requirements

- Choose according to maintenance requirements

Consider Installation Methods and Accessory Selection

- Choose installation method according to building structure

- Select suitable accessories

- Consider thermal expansion and contraction issues

Consider Cost and Cost-Effectiveness

When selecting corrugated aluminum sheets, it is necessary to comprehensively consider material cost, installation cost, service life, and maintenance cost to choose the product with the highest cost performance.

What is the disadvantage of using aluminum roofing sheets?

While aluminum roofing sheets offer many advantages, such as durability, lightweight, and corrosion resistance, they also have some potential drawbacks:

- Higher initial cost: Aluminum roofing sheets tend to be more expensive than other roofing materials, such as steel or asphalt shingles.

- Noise: Aluminum roofing may be noisier than other materials, especially during heavy rain or hail.

- Thermal expansion and contraction: Aluminum expands and contracts more with temperature changes compared to other materials.

- Dents and damage: Aluminum is softer than steel and may be more prone to denting or damage during maintenance, hailstorms, falling branches, or heavy foot traffic.

- Galvanic corrosion: When aluminum comes into contact with certain metals (such as copper or steel), galvanic corrosion may occur.