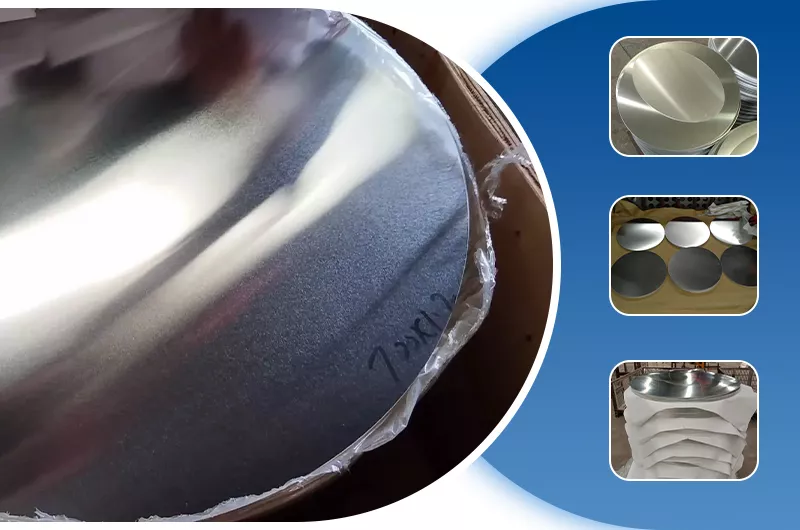

Mirror Aluminum Circle Disc

Mirror aluminum circle discs are aluminum products manufactured through multiple precision polishing and surface treatment processes. Their surface is smooth and delicate with high gloss, exhibiting excellent reflective performance, closely resembling a mirror. Thanks to the lightweight, good thermal conductivity, and ease of processing inherent to aluminum, these products are widely applied in lighting, high-end cookware, and decorative fields.

Structurally, mirror aluminum circle discs are regular flat circular aluminum sheets, with diameter and thickness customizable according to specific usage scenarios. Through factory-grade polishing and quality control processes, the products maintain consistent reflection performance and appearance, meeting functional requirements while enhancing overall visual appeal.

In terms of applications, mirror aluminum circle discs are commonly used in lighting reflectors, architectural and interior decorative components, deep-drawn high-end cookware parts, as well as various signage and industrial decorative products that demand high appearance or reflective performance, balancing practicality and aesthetics.

Mirror Aluminum Circle Disc Technical Specifications

| Property | Typical Value/Range |

| Material and Alloy | 1050, 1060, 1100, 1085 |

| Thickness | 0.15mm-10mm |

| Diameter | 20mm – 1200mm |

| Temper | O (Soft), H14, H16, H18, H24 |

| Surface Finish | Polished Mirror, Anodized Mirror, Brushed Mirror |

Mirror Aluminum Circle Disc Features

- Reflectivity: Depending on grade (standard or high-spec), the total reflectivity typically reaches 80% to over 95%.

- Alloy Used: Usually from the 1000 series (pure aluminum, e.g., 1050, 1060, or 1070) for optimal surface quality, or the 3000 series (3003) to improve strength.

- Surface Protection: Typically covered with a blue or transparent PE (polyethylene) protective film to prevent scratches during transportation and processing.

- Lightweight and Strong: Aluminum has a density of approximately 2.7g/cm³, much lower than copper or iron. It is lightweight while maintaining good strength and toughness, resisting deformation.

- Corrosion Resistance: Aluminum alloys inherently possess some corrosion resistance, which is further enhanced by anodizing or other surface treatments, maintaining good performance in various environments.

- Easy to Process: Mirror aluminum circle discs have excellent plasticity and machinability, allowing processing into various shapes through stamping, bending, drawing, and other methods to meet diverse application needs.

Mirror aluminum discs produced by ordinary mechanical or chemical polishing typically have a visible light reflectivity of 85%-92%. Anodized mirror aluminum discs have a reflectivity of 80%-88%, while high-purity aluminum processed through precision techniques can reach 92%-96%.

Hot-Selling Mirror Aluminum Circle Discs

1050 Mirror Aluminum Circle Disc

The 1050 mirror aluminum circle disc is based on high-purity aluminum (≥99.5%), combining good electrical conductivity with formability. Its surface is finely mirror-polished for high reflectivity and uniform, delicate appearance.

Typical Applications: Lighting reflectors, decorative panels, signage, standard cookware components, and other scenarios requiring high appearance quality and moderate strength.

1060 Mirror Aluminum Circle Disc

The 1060 mirror aluminum circle disc contains higher aluminum content (≥99.6%) with better ductility and deep drawing performance than 1050, suitable for complex forming processes. The mirror effect is stable with high surface smoothness.

Typical Applications: High-end cookware, lighting reflectors, deep-drawn parts, and decorative or industrial uses requiring superior forming performance.

1070 Mirror Aluminum Circle Disc

The 1070 mirror aluminum circle disc has even higher purity (≥99.7%), with excellent electrical and thermal conductivity while maintaining superb mirror surface finish.

Typical Applications: High-reflectivity lighting systems, electronic and electrical components, and precision products requiring conductive or thermal performance.

1085 Mirror Aluminum Circle Disc

The 1085 mirror aluminum circle disc is part of the ultra-high purity aluminum series (≥99.85%), with industry-leading surface brightness and reflectivity, and extremely low impurity content.

Typical Applications: High-end lighting reflectors, optical and precision industrial fields, and projects requiring extreme surface consistency and performance stability.

Color Coated Mirror Aluminum Circle Disc

Color-coated mirror aluminum circle discs use high-purity aluminum with a polished mirror surface covered by an even colored coating, combining aesthetics and durability.

Typical Applications: Lighting reflectors, high-end cookware, household appliance shells, and decorative components with high appearance and stability requirements.

Precision Processing Mirror Aluminum Circle Disc (1.25-inch Diameter)

Small-size mirror aluminum discs are made from premium aluminum, typically 14-gauge thickness, with uniform material and high surface smoothness. The discs maintain excellent stability during cutting, drilling, and forming, with neat edges, commonly used in mechanical processing, small component manufacturing, and various DIY metal projects.

Furniture and Decorative Structure Mirror Aluminum Circle

These discs are widely used in glass furniture and interior decorative structures as connectors, spacers, or adapters. They feature a clean appearance and bright mirror effect, coordinating well with glass, wood, or stainless steel, balancing decoration and practicality, and are commonly used in the furniture industry.

Stamping and Metal Craft Mirror Aluminum Blanks

These products are standard stamping aluminum discs/blanks suitable for stamping, embossing, engraving, and various metal craft processes. With good ductility and stable forming performance, they are widely applied in handmade metalwork, crafts, and creative design, serving as common basic aluminum circular blanks in metal processing.

Mirror Aluminum Circle Disc Applications

Lighting and Reflectors

Mirror aluminum circle discs are widely used in LED downlights, high-bay lights, and parabolic reflectors as core reflective substrates. Their mirror-grade surface provides excellent reflectivity, effectively improving light utilization. Compared to traditional glass reflectors, aluminum is lighter, less fragile, and more suitable for continuous, large-scale industrial production.

Cookware Manufacturing

In high-end cookware manufacturing, mirror aluminum discs are used for the inner and outer surfaces of pots, such as rice cooker lids, pressure cooker parts, and decorative functional surfaces. They offer a delicate and bright appearance, good thermal conductivity, and stable forming performance to meet high-quality and process standards.

Solar Applications

Mirror aluminum circles can be used in solar concentrators and solar heating systems, effectively focusing sunlight with their excellent mirror reflectivity, improving overall heat collection and energy conversion efficiency, making them a mature reflective material choice for solar equipment.

Decorative and Signage

In decoration and signage, mirror-finish aluminum circles are used in cosmetic packaging, luxury labels, and high-end interior decorative components. The bright, layered metallic mirror effect enhances visual impact and improves brand image and recognition.

Architectural Decoration

Mirror aluminum circle discs are suitable for interior and exterior wall surfaces, ceiling decorations, and partial architectural components, adding modernity and design tension to spaces. They can also be applied in curtain wall systems or decorative panels, ensuring lightweight while improving overall appearance quality.

Electronics

In consumer electronics and home appliances, mirror aluminum discs are used in phone and tablet cases and various appliance panels. The refined mirror effect enhances product grade while also meeting requirements for lightweight, durability, and processing flexibility.

Crafts and Packaging

In crafts and high-end packaging, mirror aluminum circles are widely applied, such as jewelry boxes, cosmetic outer packaging, and custom decorative pieces. The high-gloss mirror texture enhances product added value and provides more creativity and expressive space for design.

Mirror Aluminum Circle Disc Production Process

Typically manufactured through rolling, polishing, grinding, and painting processes. Aluminum ingots are first rolled into aluminum sheets, then mechanically or chemically polished to remove impurities and unevenness, creating a smooth mirror-like surface. Finally, painting or anodizing is applied as needed to improve corrosion and wear resistance.

Mirror Aluminum Circle Disc Selection Recommendations

When selecting mirror aluminum circle discs, consider forming process, surface reflectivity, and budget comprehensively:

Forming Difficulty

For parts requiring deep drawing, complex stretching, or precise forming, 1060 or 1070 aluminum is recommended due to their excellent ductility and flexibility, facilitating complex shapes while maintaining surface smoothness.

Reflectivity and Purity

For high-end lighting reflectors, optical devices, or projects demanding extremely high surface brightness, 1070 or 1085 mirror aluminum discs are preferred, offering high purity, low impurities, and industry-leading reflectivity and surface smoothness for precise light guidance and excellent visual effect.

Cost-Performance Ratio

For general decoration, standard lighting, or indoor applications, 1050 or 1060 aluminum can meet performance needs, balancing cost and ease of processing, making them high cost-performance options.

When selecting, focus not only on aluminum forming performance but also on surface reflectivity and project budget. Proper material choice enhances product appearance, reduces processing difficulty and overall cost, achieving the best results in high-end lighting, home appliance decoration, and industrial applications.