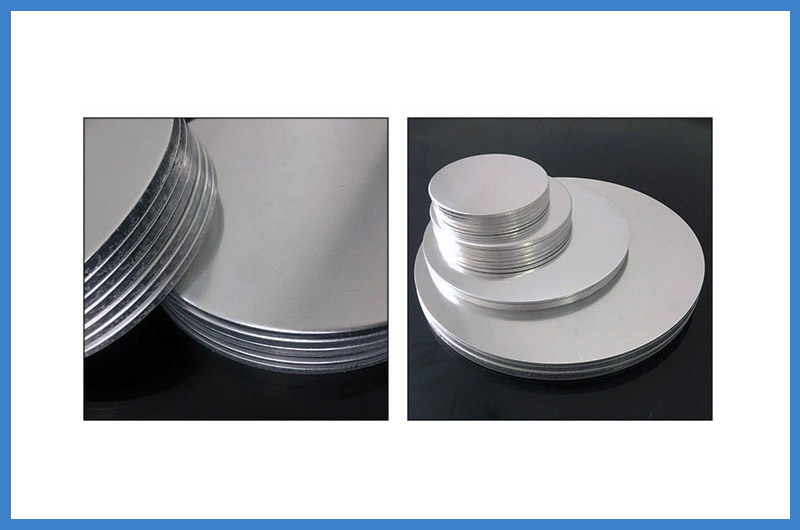

DC Aluminum Circles

The DC aluminum circle disc can effectively eliminate the internal stress generated during the casting process and improve the mechanical properties and surface quality of the aluminum sheet.

Hot-rolled aluminum discs (DC aluminum discs) are aluminum sheets formed through the hot-rolling process. This process involves heating aluminum ingots to high temperatures and then pressing them through a rolling mill to achieve the desired thickness. The hot-rolling process can significantly enhance the structural strength and ductility of the aluminum sheet, ensuring excellent performance in various applications.

The DC aluminum circle disc can effectively eliminate the internal stress generated during the casting process and improve the mechanical properties and surface quality of the aluminum sheet. Compared to the cold-rolling process, the hot-rolling process is generally more suitable for producing thicker aluminum discs.

Comparison Between DC Aluminum Circle Discs and Cast-Rolled (CC) Aluminum Discs

- 1. Performance: Compared to cast-rolled aluminum discs (CC aluminum discs), hot-rolled aluminum discs have better deep-drawing properties, making them suitable for high-demand deep-drawing applications. CC aluminum discs have poorer deep-drawing performance and are generally not suitable for deep-drawing processes.

- 2. Price: Due to differences in production processes, hot-rolled aluminum discs are usually more expensive than cast-rolled aluminum discs. CC aluminum discs are relatively cheaper due to lower processing costs, but they lack the ductility and surface treatment performance of hot-rolled aluminum discs.

Hot-rolled aluminum discs are widely used in various high-demand industrial and consumer applications due to their excellent deep-drawing performance, strong ductility, and superior surface treatment. They are the ideal choice for manufacturing high-quality aluminum products, especially for applications requiring deep-drawing or other complex processing techniques.

Performance Characteristics of DC Aluminum Circle Discs

- 1. Deep-drawing performance: Hot-rolled aluminum discs have excellent deep-drawing performance, making them suitable for producing deep-drawn cookware and other high-demand applications. Their good ductility ensures stable shape and performance during the deep-drawing process.

- 2. Ductility: Hot-rolled aluminum discs typically have strong ductility, making them suitable for further complex processing techniques such as stretching and spinning.

- 3. Surface treatment: After anodizing, hot-rolled aluminum discs can maintain a uniform color with no color difference, which is especially important for high-quality applications.

- 4. Stable performance: Due to the high-temperature effects in the hot-rolling process, the grain structure of aluminum discs is more uniform, resulting in better consistency and stability during mechanical processing.

Specifications of DC Aluminum Circle Discs

Hot-rolled aluminum discs are commonly made from 1-series, 3-series, and 5-series aluminum alloys, with the most common being 1050, 1060, 1100, 3003, and 5052. These alloys can be processed into various tempers such as O-temper, H14, H24, etc., to meet different mechanical performance requirements.

| Alloy: | 1050, 1060, 1100, 3003, 5052 |

| Temper: | O, H12, H14 |

| Thickness: | 0.4-5.0mm |

| Diameter: | 80-1600mm |

Applications of Hot-Rolled (DC) Aluminum Discs

1. Cookware

Hot-rolled aluminum discs are commonly used to manufacture kitchen utensils such as pots and pans. Their excellent thermal conductivity and workability allow these products to heat evenly and maintain good formability.

- Deep-drawn cookware: Due to their superior deep-drawing performance, hot-rolled aluminum discs are ideal for producing deep-drawn cookware such as pressure cookers and high-end cookware.

- Other cookware: Hot-rolled aluminum discs are also suitable for making various types of cookware, especially in cases where high ductility and premium surface treatment are required.

2. Lighting Fixtures

Aluminum discs are widely used in lighting equipment such as lampshades and reflectors, taking advantage of their excellent reflective properties and workability.

Typical Alloy Chemical Composition of Hot-Rolled (DC) Aluminum Discs

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al | |

| Single | Total | ||||||||||

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.05 | 0.15 | 99.50 min |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.05 | 0.15 | 99.60 min | |

| 1100 | 0.95 | 0.05-0.20 | 0.05 | - | - | 0.1 | - | 0.05 | 0.15 | 99.0min | |

| 3003 | 0.6 | 0.7 | 0.05~0.20 | 1.0~1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remainder |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remainder |