Aluminum Strip

Aluminum strips are used in industrial products. The raw materials of aluminum strips are pure aluminum or aluminum alloy cast aluminum coils, hot-rolled aluminum coils, which are cold-rolled on a rolling mill to produce thin aluminum coils of different thicknesses and widths, and then longitudinally slit into aluminum strips of different widths according to their applications.

Common alloy grades of aluminum strips include 1050, 1060, 3003, 5052, etc. According to the annealing state, they are divided into O state (soft) and H state (hard). The thickness usually ranges from 0.1 to 6 mm, and the width can be customized. They feature lightweight, corrosion resistance, and high conductivity, and are widely used in industrial, electronic, automotive, and construction fields.

Different alloys of aluminum strips (Aluminium strip) have differentiated properties. For example, 5052 alloy is suitable for vehicle components, 3003 alloy is mostly used for chemical equipment and heat exchangers, and O state aluminum strips are widely used due to their ease of processing. Haomei aluminum strip products cover pure aluminum strips, rust-resistant aluminum strips, and ultra-hard aluminum strips, with a thickness range of 0.1-6.0mm, a width of up to 2000mm, and support for customized slitting processing.

The raw materials for electronic products are no longer solely dependent on copper strips. Since aluminum’s conductivity is only slightly lower than copper, using aluminum strips as a replacement for copper strips is becoming a popular trend.

Aluminum Strip Specifications

| Category | Specification/Options | Description |

| Common Alloys | 1050, 1060, 3003, 5052, 6061 | Different alloys are suitable for different applications |

| Thickness | 0.5 mm, 1 mm, 3 mm, 4 mm, 5 mm, 6 mm | Customizable according to requirements |

| Width | 1 inch, 2 inch, 3 inch, 4 inch, 1/2 inch, 1/4 inch, 1/8 inch | Customizable according to requirements |

| Length | Commonly 10", 12", or customized according to coil length | Customizable according to requirements |

| Surface Finish | Anodized, Brushed, Polished, Powder Coated, Self-adhesive, Mirror Finish, Color Coated, Embossed, Corrugated, Painted, PVDF Coated, PE Coated, Polyester Coated, PE Laminated | Enhances decorative effect, corrosion resistance, and wear resistance |

| Color Options | Black, White, Gold, Silver (Natural Aluminum), Matte Gray, Dark Gray (Gun Gray), Bronze (Bronze/Coffee), Copper, Red (Wine Red), Blue, Green | Customizable colors to meet decorative and functional needs |

Classification of aluminum strips

According to the alloy type

According to the alloy elements contained in the aluminum strip, aluminum strips and aluminum plates are also divided into 8 series. However, the commonly used series are 1000, 3000, 5000 and 8000 series.

The alloy grades of commonly used aluminum strips are 1050, 1060, 1070, 1100, 3003, 3004, 5005, 5052, 8011, etc.

1 series3 series 5 series 8 series

-

1000 series metal pure aluminum strip

1000 series aluminum is considered commercially pure aluminum. It is at least 99% aluminum with almost no added alloys. This series of alloy aluminum strips has low strength, but has excellent corrosion resistance, processability and satisfactory anodizing properties.

1050 Aluminum Strip 1070 Aluminum Strip 1″ / 2″ / 3″ / 4″ Wide Aluminum Strips for Sale 1060 Aluminum Strip

1000 series aluminum strip is not heat treatable, but the material is easily welded, brazed and soldered.

-

3000 series alloy metal aluminum strip

Series 3 aluminum strip, also known as aluminum-manganese alloy aluminum strip, contains about 1-1.5% manganese content. This kind of aluminum strip is widely used in the field of rust prevention. Compared with pure aluminum alloy, 3 series aluminum strip has higher strength.

3005 Aluminum Strip 3105 Aluminum Strip

Although its properties cannot be enhanced by heat treatment, series 3 aluminum strips exhibit good plasticity after cold working (such as supercooling mill rolling) and annealing processes. Therefore, it has a wide range of applications in the fields of architectural decoration, electronic manufacturing, and automobile manufacturing.

-

5000 series alloy metal aluminum strip

5000 series aluminum alloys are a group of commonly used aluminum alloys that often contain magnesium as the primary alloying element. These alloys are known for their excellent corrosion resistance, high strength and good weldability.

Aluminum strips made from 5000 series alloys are commonly used in a variety of applications including automotive components, building structures, marine equipment and the transportation industry.

-

8000 series alloy metal aluminum strip

Among the 8000 series alloy metal aluminum strips, 8011 aluminum alloy strip is commonly used.

According to the surface treatment

-

Anodized Aluminum Strips

Treated with electrochemical anodizing to form a hard oxide layer, improving corrosion resistance, wear resistance, and decorative appearance. Commonly used in building decoration, electronic enclosures, and transportation equipment.

-

Brushed Aluminum Strips

Surface processed with fine brushing to create delicate linear textures, providing a modern look and anti-fingerprint effect. Suitable for appliance panels, home decoration, and furniture accessories.

-

Polished Aluminum Strips

Mechanically polished to a smooth, shiny surface for a high-end appearance. Ideal for decorative panels, signage, lighting fixtures, and premium industrial components.

-

Powder Coated Aluminium Strips

Coated with polyester powder and cured at high temperature, forming a durable, weather-resistant, and colorful surface. Used in outdoor decoration, doors and windows, curtain walls, and transportation facilities.

-

Self-adhesive Aluminium Strips

Backed with adhesive for direct application onto various substrates, offering easy installation. Commonly used for sealing, decoration, and labeling purposes.

-

Mirror Finish Aluminum Strips

Polished or electrolytically treated to create a highly reflective mirror surface. Suitable for decoration, reflective materials, and advertising signage.

-

Color Coated Aluminum Strips

Common coatings include fluorocarbon coatings, polyester coatings, etc., providing colorful and corrosion-resistant surfaces. Used in aluminum-plastic panels, aluminum blinds, aluminum ceilings, cans, and electronic products.

-

Embossed Aluminum Strips

Surface embossed with patterns or textures, enhancing decoration and anti-slip properties. Widely used in elevator doors, ceilings, and interior decoration.

-

Corrugated Aluminum Strips

Formed into corrugated shapes to increase structural strength and decorative effect. Commonly applied in roofing, wall panels, and anti-slip flooring.

-

Painted Aluminum Strips

Surface coated with liquid paint to achieve various colors and textures. Suitable for architectural decoration, furniture, and automotive parts.

-

PVDF Coated Aluminum Strips

Coated with polyvinylidene fluoride (PVDF) for excellent weather resistance, UV resistance, and color durability. Ideal for curtain walls, roofs, and exterior wall decoration.

-

PE Coated Aluminum Strips

Coated with polyethylene (PE) to enhance corrosion resistance and protect the base material. Often used in building decoration, pipelines, and electrical enclosures.

-

Polyester Coated Aluminum Strips

Polyester coating provides a smooth surface, stable color, and good UV resistance. Common applications include construction, advertising, and appliance panels.

-

PE Laminated Aluminum Strips

Aluminum strips laminated with a PE film to improve protection and weather resistance, while offering various decorative effects. Used in packaging, decoration, and anti-corrosion engineering.

Classification by Temper State

According to the different annealing states of aluminum strips, they can be divided into fully soft (O state), half-hard (H24), and fully hard (H18). The most commonly used are the fully soft series because the O state is easier to stretch and bend.

Categories of aluminum alloy strips include: pure aluminum strips, transformer aluminum strips, ultra-hard aluminum strips, fully soft aluminum strips, half-hard aluminum strips, and rust-resistant aluminum strips.

Other Classification Forms of Aluminum Strips

Pure Aluminum Strips

- 1060 Aluminum Strip: Aluminum content ≥ 99.6%, excellent electrical and thermal conductivity, suitable for applications where high strength is not required, such as signage, cookware, and electronic components.

- 1050 Aluminum Strip: Performance similar to 1060 but with better formability, commonly used in chemical equipment and storage containers.

Alloy Aluminum Strips

- 3003 Aluminum Strip: Aluminum-manganese alloy (1.0%-1.5% Mn), outstanding corrosion resistance, suitable for cookware, chemical containers, and ship components.

- 5052 Aluminum Strip: Magnesium alloy strengthened, medium strength and corrosion resistant, widely used in vehicle components.

- 6061 Aluminum Strip: Contains magnesium and silicon, suitable for aerospace fixtures and precision mechanical parts.

Special Purpose Aluminum Strips

- Transformer Aluminum Strip: Mainly 1060-O state, aluminum content ≥ 99.6%, high conductivity, used for dry transformer windings.

- Rust-Resistant Aluminum Strip: Such as 3003 series, strong corrosion resistance, suitable for humid environments.

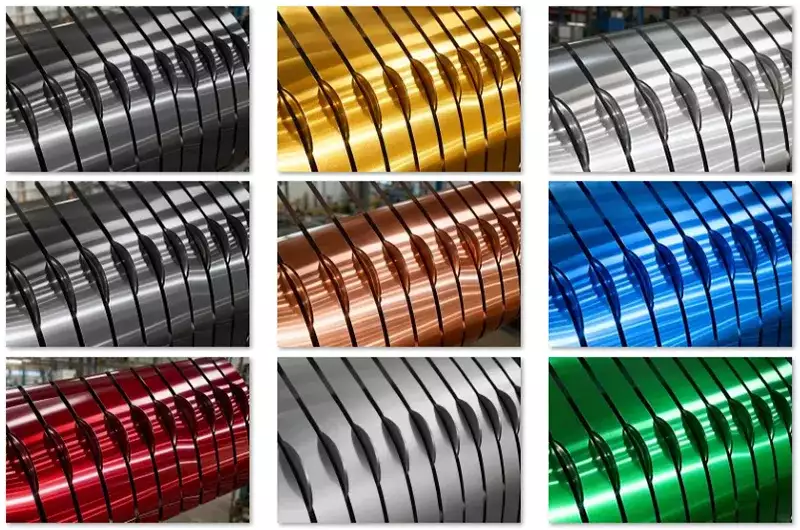

Aluminum Strip Color Options

-

Black aluminum strip

-

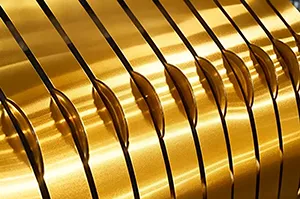

Aluminum gold strips

-

Silver aluminum strip

-

Matte Gray aluminum strip

-

Dark Gray aluminum strip

-

Copper aluminum strip

-

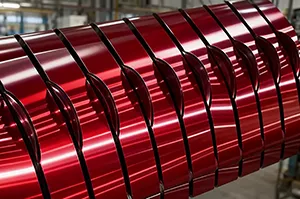

Red aluminum strip

-

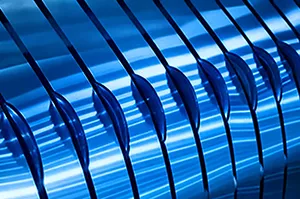

Blue aluminum strip

-

Green aluminum strip

Haomei Aluminum Strip Stock Specifications

Haomei Aluminum Strips: Alloy and Thickness Options

- aluminium strip 0.5 mm

- aluminium strip 1mm

- aluminium strip 3mm

- 4mm aluminium strip

- 5mm aluminium strip

- 6mm aluminium strip

| Item | Thickness | Alloy |

| aluminium strip 0.5 mm 1050 | 0.5 mm | 1050 |

| aluminium strip 1mm 1050 | 1 mm | 1050 |

| aluminium strip 3mm 1050 | 3 mm | 1050 |

| 4mm aluminium strip 1050 | 4 mm | 1050 |

| 5mm aluminium strip 1050 | 5 mm | 1050 |

| 6mm aluminium strip 1050 | 6 mm | 1050 |

| aluminium strip 0.5 mm 1060 | 0.5 mm | 1060 |

| aluminium strip 1mm 1060 | 1 mm | 1060 |

| aluminium strip 3mm 1060 | 3 mm | 1060 |

| 4mm aluminium strip 1060 | 4 mm | 1060 |

| 5mm aluminium strip 1060 | 5 mm | 1060 |

| 6mm aluminium strip 1060 | 6 mm | 1060 |

| aluminium strip 0.5 mm 6061 | 0.5 mm | 6061 |

| aluminium strip 1mm 6061 | 1 mm | 6061 |

| aluminium strip 3mm 6061 | 3 mm | 6061 |

| 4mm aluminium strip 6061 | 4 mm | 6061 |

| 5mm aluminium strip 6061 | 5 mm | 6061 |

| 6mm aluminium strip 6061 | 6 mm | 6061 |

| aluminium strip 0.5 mm 3003 | 0.5 mm | 3003 |

| aluminium strip 1mm 3003 | 1 mm | 3003 |

| aluminium strip 3mm 3003 | 3 mm | 3003 |

| 4mm aluminium strip 3003 | 4 mm | 3003 |

| 5mm aluminium strip 3003 | 5 mm | 3003 |

| 6mm aluminium strip 3003 | 6 mm | 3003 |

| aluminium strip 0.5 mm 5052 | 0.5 mm | 5052 |

| aluminium strip 1mm 5052 | 1 mm | 5052 |

| aluminium strip 3mm 5052 | 3 mm | 5052 |

| 4mm aluminium strip 5052 | 4 mm | 5052 |

| 5mm aluminium strip 5052 | 5 mm | 5052 |

| 6mm aluminium strip 5052 | 6 mm | 5052 |

Haomei Aluminum Strips: Alloy and Width Options

| Item | Thickness (inches) | Alloy | Width (inches) |

| 0.09" Aluminum Sheet Strip 6061 - 6" wide x 12" long | 0.09" | 6061 | 6" |

| 0.09" Aluminum Sheet Strip 6061 - 1 inch wide x coil | 0.09" | 6061 | 1" |

| 0.09" Aluminum Sheet Strip 6061 - 2 inch wide x coil | 0.09" | 6061 | 2" |

| 0.09" Aluminum Sheet Strip 6061 - 3 inch wide x coil | 0.09" | 6061 | 3" |

| 0.09" Aluminum Sheet Strip 6061 - 4 inch wide x coil | 0.09" | 6061 | 4" |

| 0.09" Aluminum Sheet Strip 6061 - 1/2 inch wide x coil | 0.09" | 6061 | 1/2" |

| 0.09" Aluminum Sheet Strip 6061 - 4" wide x 10" long | 0.09" | 6061 | 4" (10" Long) |

| 0.064" Aluminum Sheet Strip 6061 - 6" wide x 12" long | 0.064" | 6061 | 6" |

| 0.064" Aluminum Sheet Strip 6061 - 1 inch wide x coil | 0.064" | 6061 | 1" |

| 0.064" Aluminum Sheet Strip 6061 - 2 inch wide x coil | 0.064" | 6061 | 2" |

| 0.064" Aluminum Sheet Strip 6061 - 3 inch wide x coil | 0.064" | 6061 | 3" |

| 0.064" Aluminum Sheet Strip 6061 - 4 inch wide x coil | 0.064" | 6061 | 4" |

| 0.064" Aluminum Sheet Strip 6061 - 1/2 inch wide x coil | 0.064" | 6061 | 1/2" |

| 0.064" Aluminum Sheet Strip 6061 - 4" wide x 10" long | 0.064" | 6061 | 4" (10" Long) |

| 1/4 inch Aluminum Sheet Strip 6061 - 6" wide x 12" long | 1/4" | 6061 | 6" |

| 1/4 inch Aluminum Sheet Strip 6061 - 1 inch wide x coil | 1/4" | 6061 | 1" |

| 1/4 inch Aluminum Sheet Strip 6061 - 2 inch wide x coil | 1/4" | 6061 | 2" |

| 1/4 inch Aluminum Sheet Strip 6061 - 3 inch wide x coil | 1/4" | 6061 | 3" |

| 1/4 inch Aluminum Sheet Strip 6061 - 4 inch wide x coil | 1/4" | 6061 | 4" |

| 1/4 inch Aluminum Sheet Strip 6061 - 1/2 inch wide x coil | 1/4" | 6061 | 1/2" |

| 1/4 inch Aluminum Sheet Strip 6061 - 4" wide x 10" long | 1/4" | 6061 | 4" (10" Long) |

| 1/8 inch Aluminum Sheet Strip 6061 - 6" wide x 12" long | 1/8" | 6061 | 6" |

| 1/8 inch Aluminum Sheet Strip 6061 - 1 inch wide x coil | 1/8" | 6061 | 1" |

| 1/8 inch Aluminum Sheet Strip 6061 - 2 inch wide x coil | 1/8" | 6061 | 2" |

| 1/8 inch Aluminum Sheet Strip 6061 - 3 inch wide x coil | 1/8" | 6061 | 3" |

| 1/8 inch Aluminum Sheet Strip 6061 - 4 inch wide x coil | 1/8" | 6061 | 4" |

| 1/8 inch Aluminum Sheet Strip 6061 - 1/2 inch wide x coil | 1/8" | 6061 | 1/2" |

| 1/8 inch Aluminum Sheet Strip 6061 - 4" wide x 10" long | 1/8" | 6061 | 4" (10" Long) |

| .190" Aluminum 5052 H32 Strip - 6" wide x 12" long | 0.190" | 5052 | 6" |

| .190" Aluminum 5052 H32 Strip - 1 inch wide x coil | 0.190" | 5052 | 1" |

| .190" Aluminum 5052 H32 Strip - 2 inch wide x coil | 0.190" | 5052 | 2" |

| .190" Aluminum 5052 H32 Strip - 3 inch wide x coil | 0.190" | 5052 | 3" |

| .190" Aluminum 5052 H32 Strip - 4 inch wide x coil | 0.190" | 5052 | 4" |

| .190" Aluminum 5052 H32 Strip - 1/2 inch wide x coil | 0.190" | 5052 | 1/2" |

| .190" Aluminum 5052 H32 Strip - 4" wide x 10" long | 0.190" | 5052 | 4" (10" Long) |

| .190" Aluminum 3003 H14 Strip - 6" wide x 12" long | 0.190" | 3003 | 6" |

| .190" Aluminum 3003 H14 Strip - 1 inch wide x coil | 0.190" | 3003 | 1" |

| .190" Aluminum 3003 H14 Strip - 2 inch wide x coil | 0.190" | 3003 | 2" |

| .190" Aluminum 3003 H14 Strip - 3 inch wide x coil | 0.190" | 3003 | 3" |

| .190" Aluminum 3003 H14 Strip - 4 inch wide x coil | 0.190" | 3003 | 4" |

| .190" Aluminum 3003 H14 Strip - 1/2 inch wide x coil | 0.190" | 3003 | 1/2" |

| .190" Aluminum 3003 H14 Strip - 4" wide x 10" long | 0.190" | 3003 | 4" (10" Long) |

| .125" Aluminum 3003 H14 Strip - 6" wide x 12" long | 0.125" | 3003 | 6" |

| .125" Aluminum 3003 H14 Strip - 1 inch wide x coil | 0.125" | 3003 | 1" |

| .125" Aluminum 3003 H14 Strip - 2 inch wide x coil | 0.125" | 3003 | 2" |

| .125" Aluminum 3003 H14 Strip - 3 inch wide x coil | 0.125" | 3003 | 3" |

| .125" Aluminum 3003 H14 Strip - 4 inch wide x coil | 0.125" | 3003 | 4" |

| .125" Aluminum 3003 H14 Strip - 1/2 inch wide x coil | 0.125" | 3003 | 1/2" |

| .125" Aluminum 3003 H14 Strip - 4" wide x 10" long | 0.125" | 3003 | 4" (10" Long) |

| 0.032" Aluminum Sheet Strip 3003 H14 - 6" wide x 12" long | 0.032" | 3003 | 6" |

| 0.032" Aluminum Sheet Strip 3003 H14 - 1 inch wide x coil | 0.032" | 3003 | 1" |

| 0.032" Aluminum Sheet Strip 3003 H14 - 2 inch wide x coil | 0.032" | 3003 | 2" |

| 0.032" Aluminum Sheet Strip 3003 H14 - 3 inch wide x coil | 0.032" | 3003 | 3" |

| 0.032" Aluminum Sheet Strip 3003 H14 - 4 inch wide x coil | 0.032" | 3003 | 4" |

| 0.032" Aluminum Sheet Strip 3003 H14 - 1/2 inch wide x coil | 0.032" | 3003 | 1/2" |

| 0.032" Aluminum Sheet Strip 3003 H14 - 4" wide x 10" long | 0.032" | 3003 | 4" (10" Long) |

| 0.016" Aluminum Sheet Strip 3003 H14 - 6" wide x 12" long | 0.016" | 3003 | 6" |

| 0.016" Aluminum Sheet Strip 3003 H14 - 1 inch wide x coil | 0.016" | 3003 | 1" |

| 0.016" Aluminum Sheet Strip 3003 H14 - 2 inch wide x coil | 0.016" | 3003 | 2" |

| 0.016" Aluminum Sheet Strip 3003 H14 - 3 inch wide x coil | 0.016" | 3003 | 3" |

| 0.016" Aluminum Sheet Strip 3003 H14 - 4 inch wide x coil | 0.016" | 3003 | 4" |

| 0.016" Aluminum Sheet Strip 3003 H14 - 1/2 inch wide x coil | 0.016" | 3003 | 1/2" |

| 0.016" Aluminum Sheet Strip 3003 H14 - 4" wide x 10" long | 0.016" | 3003 | 4" (10" Long) |

Other common aluminum strips

- 10mm aluminium strip

- 15mm aluminium strip

- 20mm aluminium strip

- 40mm aluminium strip

- 25 x 3 aluminium strip

Common Aluminum Strip Metal Temper

The common states of aluminum strips are O state and H state. O means soft state and H means hard state. O and H can be followed by numbers to indicate the degree of softness, hardness and annealing degree.

- O

- H24

- H18

According to the different annealing states of aluminum strips, aluminum strips can be divided into full soft (o state), semi-hard (H24) and full hard (h18). The most commonly used should belong to the full soft series, because the O state is easier to stretch and bend.

Performance and Applications of Different Aluminum Alloy Series

Common aluminum strip alloy grades include 1050, 1060, 1070, 1100, 3003, 3004, 5005, 5052, 8011, etc. Common states include O state and H state. O indicates soft, H indicates hard. Numbers following O or H indicate the degree of softness/hardness or annealing.

Common alloys include:

- 1060 (Pure Aluminum): Aluminum content ≥ 99.6%, excellent conductivity and corrosion resistance, commonly used for transformer windings, armored cables, and heat sinks.

- 3003 (Aluminum-Manganese Alloy): Strong corrosion resistance, good workability, suitable for chemical equipment, heat exchangers, and architectural decoration.

- 5052 (Aluminum-Magnesium Alloy): Higher strength, used for automobile fuel tanks, ship sheet metal parts, and structural components.

- 8011 (Aluminum-Silicon Alloy): High temperature resistance, commonly used for packaging foil and electronic components.

State Classification

- O State (Soft): Good ductility, easy to process, suitable for deep drawing, bending, and other complex forming processes.

- H State (Hard): Strengthened through cold working, e.g., H24 (half-hard) used for structural parts requiring medium strength.

1060 Pure Aluminum Strip

- Feature Description: Aluminum content ≥ 99.6%, excellent thermal and electrical conductivity, good plasticity and workability, low strength, very easy for deep drawing, stretching, and other forming processes.

- Typical Applications: Mainly used in scenarios requiring excellent corrosion resistance and formability but minimal load-bearing. Ideal for chemical equipment liners handling corrosive media, coatings, gaskets, and high-purity food industry utensils.

1100 Pure Aluminum Strip

- Feature Description: Aluminum content ≥ 99.0%, performance very similar to 1060, excellent formability and high corrosion resistance, slightly higher strength than 1060 but still low.

- Typical Applications: Commonly used in chemical products, food industry equipment, and storage containers. Particularly suitable for deep drawing or spinning of concave vessels (e.g., pots, bowls, cans), thin plate components, welded parts, heat exchanger fins, printing plates, nameplates, and reflective material substrates.

8011 Aluminum-Iron-Silicon Alloy Strip

- Feature Description: Higher strength than 1xxx series pure aluminum (e.g., 1100), good ductility, rust resistance, deep drawing performance, heat resistance, and good surface finish.

- Typical Applications: Common material for bottle caps and food packaging foil, widely used in heat sinks, brazing materials, cable strips, etc. In the chemical field, can be used for container lids and covers requiring slightly higher strength than 1100.

3003 Aluminum-Manganese Alloy Strip

- Feature Description: Strength approximately 20% higher than 1xxx pure aluminum strips, good formability, corrosion resistance, and weldability. A cost-effective "strength-performance" balance alloy.

- Typical Applications: Preferred when good formability and corrosion resistance are needed, with higher strength than 1xxx alloys. Widely used for liquid transport tanks and tankers, pressure vessels, chemical equipment, aircraft fuel tanks, oil pipelines, kitchen equipment, and interior architectural panels.

3004/3104 Aluminum Strip

- Feature Description: Higher strength than 3003 while maintaining good formability and corrosion resistance, particularly excellent deep drawing performance.

- Typical Applications: Most classic and widely used for beverage can bodies, also used for parts requiring higher strength than 3003, such as chemical production and storage equipment, architectural panels, cable conduits, lighting components, etc.

5052 Aluminum-Magnesium Alloy Strip

- Feature Description: Excellent formability, outstanding corrosion resistance (especially seawater resistance), weldability, and fatigue strength.

- Typical Applications: Used for aircraft fuel tanks, pipelines, vehicles, ship sheet metal parts, instrument casings, street lamp brackets, hardware products, etc. If pure aluminum or 3003 series strength is insufficient, 5052 is a common upgrade choice.

Summary Comparison (Sorted by Alloy Series)

| Alloy Aluminum Strip | Main Characteristics | Typical Applications (Aluminum Strip) |

| 1060 Aluminum Strip | Best corrosion resistance, best formability, excellent thermal and electrical conductivity, lowest strength. | Chemical equipment lining, high-purity food utensils, deep-drawn products requiring excellent formability. |

| 1100 Aluminum Strip | Good corrosion resistance, excellent formability, very low strength. | Chemical/food containers, deep-drawn or spun vessels, sheet metal parts, heat exchangers, nameplates. |

| 8011 Aluminum Strip | Higher strength than 1xxx pure aluminum, good deep drawing performance, rust resistance, and surface finish. | Bottle cap material, food packaging foil, heat sinks, brazing material, cable tape. |

| 3003 Aluminum Strip | Good corrosion resistance and formability, higher strength than pure aluminum, well-balanced overall properties. | Liquid storage tanks, pressure vessels, chemical equipment, aircraft fuel tanks, kitchen equipment, interior decoration. |

| 3004 Aluminum Strip | Higher strength than 3003, excellent deep drawing performance, good corrosion resistance. | Beverage can bodies, demanding chemical equipment, building siding, lighting components. |

| 5052 Aluminum Strip | Highest strength among medium-strength alloys, excellent seawater corrosion resistance, good fatigue strength and weldability. | Aircraft fuel tanks, ship and vehicle sheet metal parts, instrument components, containers and hardware parts requiring higher strength. |

Selection Recommendations:

- For ultimate corrosion resistance and formability, with almost no strength requirement: choose 1060 or 1100.

- For food packaging, bottle caps, requiring good deep drawing performance and certain strength: choose 8011.

- For balanced properties and slightly higher strength: choose 3003.

- For deep-drawn cans or applications with higher strength requirements: choose 3004.

- For medium strength and better seawater corrosion resistance: choose 5052.

Aluminum Strip Applications

The specific uses of aluminum strips are mainly: transformer aluminum strips (transformer aluminum foil), aluminum strips for high-frequency welding hollow aluminum strips, aluminum strips for fin heat sinks, aluminum strips for cables, aluminum strips for stamping, aluminum strips for aluminum edge strips, etc.

| Type of Aluminium Strip | Alloy | Common Thickness | Primary Application |

| aluminium strip for transformer winding | 1050 1060 1070 | 0.2-3.0 mm | Electrical conductivity, insulation |

| decorative aluminum strips | 3003 | 0.2-2.0 mm | Aesthetic enhancement in interiors and exteriors |

| aluminium Strip for Cosmetics packaging | 1070 | 0.03-0.3 mm | Forming tubes and containers for cosmetics packaging |

| aluminium window strips | 6063 | 0.5-3.0 mm | Structural support and finish for window frames |

| aluminium strip for closures | 3105 or 8011 | 0.15-0.3 mm | Bottle caps and closures |

| aluminium fin strip | 1000 3000 4000 5000 | 0.1-0.3 mm | Heat transfer in air conditioning and refrigeration |

| aluminium strips for stairs | 6061 or 6063 | 1.0-3.0 mm | Safety and aesthetics in stair construction |

| aluminum floor strip | 3003 | 1.0-3.0 mm | Edge protection and transitions between floor surfaces |

| aluminium nose strip | 3003 1060 1050 | 0.5-2.0 mm | Smooth surface, no burrs, rounded corners, easy to bend |

| aluminum non skid tread strips | 5052 | 1.0-3.0 mm | Non-slip surfaces in industrial and marine environments |

| self adhesive aluminium strip | 3003 or 5052 | 0.5-2.0 mm | Easy installation with adhesive backing |

| caravan aluminium trim strip | 6063 | 0.5-2.0 mm | Decorative and protective trim in caravan interiors |

| aluminium expansion joint cover strips | 6061 | 1.0-3.0 mm | Cover and protect expansion joints in construction |

| aluminum flooring transition strips | 6063 | 1.0-3.0 mm | Smooth transition between flooring materials |

Aluminum Strip Application Specification Parameter Table

| Application | Description |

| 3105 H14 H16 Aluminium Coil Strip and Foil for Screw Caps | The key properties of 3105 H14 H16 aluminum suitable for screw caps are its good corrosion resistance, formability and sufficient strength for threading and sealing applications. |

| 3004 3104 H19 Aluminum Coil Strip for Can Body | The can body is made of 3004 3104 aluminum coil, which has excellent deep drawing and ductility and meets EN 541 standards. |

| 1060 O H22 Aluminum Coil Strip for Vial Seals | 1060 O H22 aluminum coil has excellent properties such as high purity, formability and corrosion resistance, which is ideal for vial sealing |

| 1050 1060 1070 3C Digital Aluminum Coil Strip | 1050, 1060 and 1070 aluminum alloys are used in 3C digital applications due to their high conductivity, excellent thermal management and easy forming into complex shapes. |

| 5252 3C Digital Shell Aluminum Coil Strip | 5252 aluminum alloy is widely used in 3C digital housings due to its high strength, good corrosion resistance and good formability. It is an ideal material for electronic equipment protective shells and structural parts. |

| 5005 H14 H34 3C Digital Shell Aluminum Coil Strip | 5005 H32 H34 aluminum alloy is used in 3C digital housing applications due to its good corrosion resistance, anodizing performance, good surface finish and moderate strength. |

| 5052 H32 H34 3C Digital Shell Aluminum Coil Strip | 5052 H32 H34 aluminum alloy is used in 3C digital housings due to its good corrosion resistance, good formability and high strength. It is an ideal choice for protective housings and housings for electronic devices. |

| Aluminum Plastic Composite Strip for Cables and Optical Cables | Aluminum-plastic composite tape for cables and optical cables is a multi-layer material composed of aluminum and plastic, which has shielding, strength and durability to protect and insulate cables. |

| Non-clad Brazing Aluminum Strip for Vehicles | Unclad brazing aluminum strip for automobiles is an aluminum strip designed for high-temperature brazing applications, which can provide strong and durable joints in automotive heat exchangers and other components without a coating. |

| 6082 T4/O Automotive Aluminum Coil Strip | 6082 T4 O automotive parts aluminum strip is used to manufacture automotive body frames and conductive parts. |

| Aluminum strip for lamp base 3004 | 3004 aluminum strip has excellent formability and corrosion resistance and can be used to manufacture lamp holders. |

| Aluminum Strip for Air Duct Materials 8011 | 8011 aluminum strip is selected because of its high ductility, corrosion resistance and heat resistance, which is suitable for manufacturing air ducts. |

Haomei provides aluminum strip products form

| Type | Description | Typical Uses |

| Aluminium Edging Strip | Used for finishing and protecting edges of surfaces or panels. | Edge protection, finishing |

| Flat Aluminium Strip | Straight, flat profile for trim or framing applications. | Trim, framing |

| Angle Aluminium Strip | Right-angle profile for structural purposes or corner guards. | Structural framing, corner protection |

| Half Round Aluminium Strip | Semi-circular cross-section, decorative or trim applications. | Decorative trim |

| Aluminium U Strip | U-shaped profile used in framing and edge protection. | Framing, edge protection |

| Aluminium Z Strip | Z-shaped profile for joining or decorative purposes. | Joining materials, decorative trim |

| L Shaped Aluminium Strip | L-shaped profile for framing, edging, or structural uses. | Framing, edging, structural support |

| Aluminium T Strip | T-shaped profile for transitions between different materials or surfaces. | Floor transitions, edge finishing |

| Right Angle Aluminium Strip | Similar to angle aluminium strip, used for creating right-angle connections. | Structural connections, framing |

| Small Aluminium Strips | Narrow, small-sized strips for sealing, framing, or decorative trim. | Sealing, framing, decorative trim |

| DPC Aluminium Strip | Processed for specific deep processing capabilities, used in electronics. | Electronics, precision applications |

| Aluminium Beading Strip | Used for decorative or functional purposes like edge protection or joining. | Decorative trim, edge protection, panel joining |

| Aluminium Corner Strips | Designed to reinforce or protect corners of surfaces or structures. | Corner reinforcement, protection |

| Aluminium Foil Strips | Thin sheets used for packaging, insulation, or cooking. | Packaging, insulation, cooking |

How to Choose Aluminum Strips?

- Clarify the Application: Determine the intended use of the aluminum strip and select the appropriate alloy and temper. For example, soft (O state) is needed for deep drawing, while half-hard or fully hard may be required for heat sinks.

- Determine Specifications: Accurately measure or calculate the required thickness, width, and length.

- Choose a Supplier: Look for reputable aluminum manufacturers or distributors to ensure stable material quality and accurate composition.

- Check Surface Quality: A good aluminum strip should have a smooth and flat surface, free of scratches, oil stains, oxidation spots, and roller marks.

- Request a Material Certificate: Standard products come with a Material Test Certificate (MTC) to ensure the material meets specifications.

Purchasing Recommendations: Performance Matching

- Conductivity: Prefer alloys 1060 or 1100, with conductivity ≥ 60% IACS.

- Corrosion Resistance: For coastal or high-humidity environments, 3004 or 5052 alloys are recommended, with salt spray test ≥ 1000 hours.

- Workability: For complex forming (e.g., deep drawing), O state material with hardness ≤ 50HV is recommended.

Aluminum strips are a fundamental yet powerful industrial material. From everyday pharmaceutical packaging to high-end audio equipment, as well as critical industrial manufacturing and power transmission, they are indispensable. Their specific properties entirely depend on the aluminum alloy grade, heat treatment state, and size specifications used.

How to identify the quality of aluminum strips?

One way is to look at the edges of the aluminum film to see if it reflects light. High-quality aluminum films will not peel off after being covered at high temperatures, while low-quality aluminum films will peel off easily due to insufficient viscosity. Compare the glossiness of several samples under light and choose the one with the best gloss.