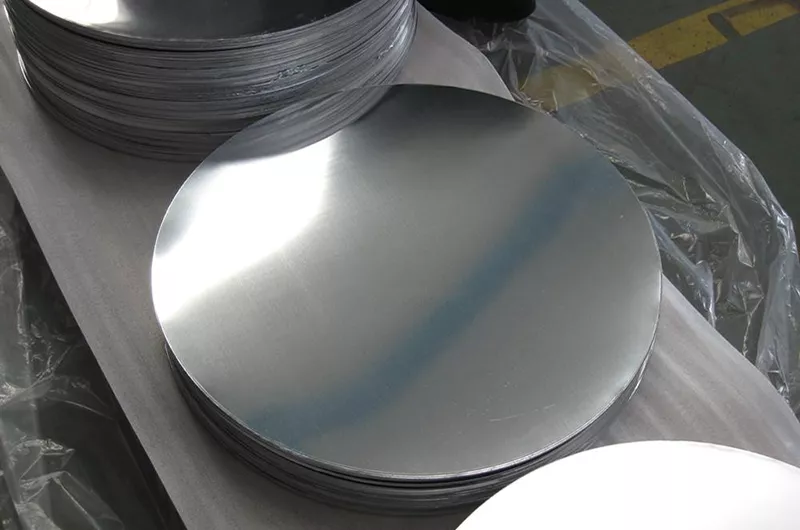

Aluminum Stamping Discs

What Are Aluminum Stamping Discs

Aluminum stamping discs (also known as aluminum circles or aluminum round discs) are circular aluminum products cut from aluminum coils or sheets through a stamping process. They are widely used semi-finished materials, mainly applied in various aluminum products that require subsequent processing such as deep drawing, stretching, and spinning.

Round Stamping Aluminum Blanks Technical Specifications

A variety of diameters are available depending on project size (for example, ½ inch, 1 inch, 2 inches, 3 inches, etc.).

Thickness (gauge) affects the ease of stamping — thicker discs are more resistant to bending and can achieve deeper impressions.

| Parameter | Standard Range | Special Customization | Tolerance Requirement |

| Thickness | 0.2mm~10mm | 0.1mm~12mm | ±0.02mm~±0.05mm |

| Diameter | 100mm~800mm | 20mm~1250mm | ±0.1mm~±0.3mm |

| Flatness | ≤0.5mm/m | Adjustable according to requirements | d/D≤0.005 (d = wave height, D = diameter) |

| Edge Burr | ≤0.05mm | ≤0.02mm for high-precision products | No obvious protruding burrs; can be removed with light pressure |

Typical Sizes & Gauges

| Gauge | Thickness (Approx.) | Best Use Case |

| 24–20 ga | 0.5mm – 0.8mm | Thin/lightweight; easy to cut with shears or punch. |

| 18–16 ga | 1.0mm – 1.3mm | Standard for jewelry; thick enough to stamp both sides. |

| 14–10 ga | 1.6mm – 2.5mm | Heavy-duty; used for keychains, industrial tags, or deep "coining." |

Common Dimensions (Diameter)

Blanks are typically categorized by their diameter in inches or millimeters.

- Small (Jewelry/Charms): 3/8", 1/2", 5/8", 3/4" (approx. 10mm – 19mm)

- Medium (ID Tags/Keychains): 7/8", 1", 1 1/8", 1 1/4" (approx. 22mm – 32mm)

- Large (Valve Tags/Industrial): 1 1/2", 2", 2 1/2", 3" (approx. 38mm – 76mm)

Aluminum Stamping Circle Alloy Types

- 1100 or 1060 (pure aluminum): Very soft, "as easy to stamp as butter." Most commonly used by hobbyists.

- 3003 Aluminum Alloy: The most common commercial grade. Balanced strength and workability; excellent corrosion resistance.

- 5052 or 6061: Harder industrial-grade alloys. More suitable for structural components or items that need to withstand saltwater.

Stamping 1100 Aluminum Circle

Stamping 1100 Aluminum Circles are made from high-purity aluminum (≥99.0%), offering excellent ductility and outstanding formability. With a smooth surface and consistent thickness, these circles are ideal for light stamping, deep drawing, and decorative applications. They are widely used in cookware, lighting components, nameplates, and aluminum signs where surface quality is critical.

Key Features:

- High aluminum purity with excellent workability

- Smooth, clean surface for superior finishing

- Good corrosion resistance

- Suitable for shallow to medium stamping processes

Stamping 1060 Aluminum Circle

Stamping 1060 Aluminum Circles contain 99.6% aluminum, providing higher conductivity and better elongation than standard commercial grades. They deliver stable stamping performance with low risk of cracking and are ideal for precision stamping and deep drawing operations. Common applications include cookware bases, capacitor shells, lamp reflectors, and industrial components.

Key Features:

- High elongation and excellent formability

- Uniform thickness and tight dimensional tolerance

- Excellent thermal and electrical conductivity

- Ideal for deep drawing and repeated stamping

Stamping 3003 Aluminum Circle

Stamping 3003 Aluminum Circles are alloyed with manganese, giving them higher strength than pure aluminum while maintaining good formability. They are well-suited for medium-strength stamping applications requiring durability and corrosion resistance. Typical uses include cookware, containers, automotive parts, and general industrial stampings.

Key Features:

- Higher strength than 1xxx series aluminum

- Good corrosion resistance and weldability

- Stable performance in medium-load stamping

- Suitable for cookware and industrial applications

Stamping 5052 Aluminum Circle

Stamping 5052 Aluminum Circles are magnesium-alloyed aluminum products known for their excellent fatigue strength and corrosion resistance. They perform well in demanding stamping environments and are ideal for parts requiring higher mechanical strength. These circles are commonly used in automotive components, marine hardware, pressure vessels, and structural stampings.

Key Features:

- High strength with excellent fatigue resistance

- Superior corrosion resistance, especially in marine environments

- Good formability for complex stamping shapes

- Suitable for high-performance industrial applications

Aluminum Stamping Circle Surface Finishes

The "appearance" of the discs depends on their surface treatment:

- Mill/Rolled Surface: Dull and matte, may have some minor scratches. Requires sanding or polishing.

- Burnished/Polished: Bright and smooth, ready for stamping immediately.

- Brushed/Satin: Has a soft matte texture, resistant to fingerprints.

- Anodized: Coated in various colors (blue, red, gold, etc.). The color is part of the metal and will not peel, but stamping will expose the underlying silver aluminum.

Anodized Aluminum Stamping Blanks Discs

Anodized aluminum stamping blank discs feature a hard, protective oxide layer formed through an electrochemical process. This anodized surface significantly improves corrosion resistance, wear resistance, and surface hardness while providing a uniform, decorative appearance. These discs are ideal for stamping applications where enhanced durability, color consistency, or outdoor performance is required, such as nameplates, decorative panels, signage, and architectural components.

Polished Aluminum Stamping Blanks

Polished aluminum stamping blanks are mechanically finished to achieve a smooth, mirror-like or high-gloss surface. This finish enhances reflectivity and visual appeal, making the blanks suitable for products where appearance is critical. With consistent thickness and clean edges, polished aluminum blanks are commonly used in decorative stampings, lighting components, reflectors, and premium consumer products.

Mill Finish Aluminum Stamping Circle

Mill finish aluminum stamping circles are supplied in their natural, untreated state directly after rolling. They retain the original aluminum surface with minimal processing, offering a cost-effective solution for general stamping applications. These circles provide good formability and uniform thickness, making them suitable for further processing such as anodizing, coating, painting, or deep drawing in cookware and industrial parts.

Brushed Aluminum Stamping Circle

Brushed aluminum stamping circles feature a linear, textured surface created by controlled abrasion. This finish reduces surface glare while delivering a modern, industrial aesthetic and improved scratch concealment. Brushed aluminum circles are widely used in decorative stampings, appliance panels, lighting fixtures, and architectural components where both appearance and durability are important.

Aluminum Stamping Circle Features

- Lightweight: Density is only 2.7g/cm³, about 1/3 of steel.

- Excellent ductility: Suitable for stamping and stretching into complex shapes.

- Good thermal conductivity: Ideal material for cookware and heat sinks.

- Corrosion resistance: Forms an oxide layer on the surface that protects the interior from corrosion.

- Recyclable: Environmentally friendly and sustainable, with high recycling efficiency.

- Diverse surface treatments: Can be anodized, painted, or laminated to enhance performance and aesthetics.

Aluminum Stamping Circle Material and Temper Selection

| Alloy Series | Representative Grades | Main Features | Typical Applications |

| 1000 Series (Pure Aluminum) | 1050, 1060, 1100 | Aluminum content ≥99%, excellent ductility, good weldability, low cost | Cookware, lighting, simple drawn parts |

| 3000 Series (Aluminum-Manganese Alloy) | 3003, 3105 | Higher strength than pure aluminum, good corrosion resistance and workability | Pots, water tanks, automotive components, chemical equipment |

| 5000 Series (Aluminum-Magnesium Alloy) | 5052, 5083 | High strength, excellent corrosion resistance, suitable for marine environments | Marine fittings, pressure vessels, high-end cookware |

| 8000 Series (Aluminum-Lithium Alloy) | 8011 | Good workability, suitable for cans, caps, and other thin products | Food packaging, pharmaceutical aluminum foil, bottle caps |

Common tempers for Aluminum Stamping Circles:

- O temper (annealed): Softest, best ductility, suitable for deep drawing and stretching, the mainstream choice for stamping discs.

- H temper (work-hardened): H14, H16, H18, etc., increasing strength sequentially, suitable for products requiring higher strength.

- H2 temper (work-hardened + partial annealing): H24, balancing strength and ductility.

Aluminum Stamping Circle Applications

Cookware and Kitchenware

Aluminum stamping circles are extensively used for manufacturing pots, pans, frying pans, pressure cookers, kettle bodies, and lids. Their uniform thickness and high ductility ensure consistent deep drawing and spinning performance, resulting in smooth surfaces and even heat distribution.

Lighting and Reflectors

In the lighting industry, aluminum stamping circles are used for lamp shades, reflectors, LED housings, and decorative lighting components. Their good reflectivity, ease of forming, and compatibility with polishing or anodizing make them ideal for both functional and aesthetic designs.

Electrical and Electronic Components

These circles are commonly applied in capacitor shells, battery cases, motor covers, and electronic enclosures. Aluminum’s thermal conductivity and corrosion resistance help protect internal components while maintaining lightweight structures.

Automotive and Transportation

Aluminum stamping circles are used to produce fuel tank caps, heat shields, trim parts, sensor housings, and other formed components. Their strength-to-weight ratio contributes to vehicle weight reduction and improved fuel efficiency.

Packaging and Containers

They are widely used in the production of aerosol cans, cosmetic containers, food containers, and bottle caps. Aluminum stamping circles provide excellent sealing performance, hygiene, and recyclability.

Industrial and Decorative Products

Aluminum stamping circles are also applied in nameplates, signs, medals, cookware bottoms, architectural decorations, and hardware accessories. Their smooth surface allows for easy printing, embossing, and surface treatments such as anodizing or brushing.

Haomei Aluminum Stamping Circle Quality Control

At Haomei Aluminum, we strictly control the quality of aluminum stamping circles to ensure that every batch meets our customers' high processing standards:

- Dimensional Accuracy: Strictly control disc diameter and thickness tolerances to ensure perfect compatibility with customers' subsequent stamping molds, improving production efficiency.

- Surface Quality: Discs have a flat and smooth surface, free of scratches, oil stains, oxidation spots, or impurities, ensuring excellent appearance and suitability for subsequent surface treatments.

- Edge Quality: Precisely control burr height, with smooth, burr-free edges to effectively prevent scratches and assembly issues.

- Mechanical Properties: Strictly ensure that the mechanical properties of each alloy grade meet standards, with special attention to elongation, guaranteeing smooth stamping and good forming.

- Chemical Composition: Strictly test composition according to alloy grade standards to ensure stable and reliable performance, avoiding material deviations that could affect processing or usage.

Through this rigorous quality control system, Haomei Aluminum provides customers with stable, high-quality aluminum stamping circles, supporting smooth precision manufacturing.

Aluminum Stamping Circle Production Process Flow

- Raw Material Preparation: Select aluminum coils/sheets that meet requirements and clean the surface to remove oil and oxide layers.

- Cutting/Blanking: Cut aluminum coils into sizes suitable for stamping.

- Precision Stamping: Use high-speed presses and custom molds to obtain circular blanks.

- Annealing: Perform high-temperature annealing for O temper products to relieve internal stress and improve ductility.

- Surface Treatment: According to requirements, perform cleaning, passivation, lamination, and other treatments to protect the surface from damage.

- Inspection and Sorting: Check diameter, thickness, flatness, and surface quality, removing defective products.

- Packaging and Storage: Use moisture-proof paper and bubble wrap to prevent scratches and oxidation during transportation.

Aluminum Stamping Circle Common Problems and Solutions

| Problem | Cause | Solution |

| Stamping Cracks | Improper material temper, unreasonable die clearance, insufficient lubrication | Use O temper material, adjust die clearance, apply special aluminum stamping lubricant |

| Surface Scratches | Rough die surface, defective raw materials, friction during transportation | Polish dies, strictly inspect raw materials, improve packaging methods |

| Excessive Edge Burr | Worn die edges, stamping speed too fast | Regular die maintenance, adjust stamping parameters, optimize die design |

| Springback Deformation | Aluminum alloy has low modulus of elasticity; stress is released after stamping | Pre-compensate die design, add shaping processes, control annealing process |

| Die Sticking | Material too soft, die temperature too high, poor lubrication | Cool the die, use anti-stick lubricant, optimize die surface treatment |

Aluminum Stamping Circle Buying Guide

- Clarify Application Requirements: Choose the appropriate alloy grade and temper based on product use.

- Determine Specifications: Accurately calculate required diameter and thickness, considering allowances for subsequent processing.

- Choose a Reputable Manufacturer: Ensure products meet national standards and provide material certificates and inspection reports.

- Consider Cost Balance: Pure aluminum is low-cost, alloy aluminum has better performance; choose based on cost-effectiveness.

- Pay Attention to Surface Condition: Select suitable surface treatment according to subsequent processing requirements.

What is the difference between casting and stamping aluminum?

| Category | Cast Aluminum | Stamped Aluminum |

| Manufacturing Process | Aluminum is melted and poured into molds for shaping. Common methods include sand casting, die casting, gravity casting, etc. | Aluminum sheets are shaped using mechanical stamping or die cutting, suitable for thin-walled and simple-shaped products. |

| Material Properties | Has a relatively coarse grain structure with lower strength but can be used to make parts with complex shapes. | Features a finer grain structure and higher strength, with good ductility, suitable for products requiring high precision and strength. |

| Applications | Suitable for making complex and durable parts, such as engine components, mechanical parts, tool housings, etc. | Ideal for producing large quantities of precise thin sheet products, such as automotive body panels, kitchen utensils, and electronic housings. |

| Surface Treatment | The surface is relatively rough and often requires further processing or treatment, such as polishing or coating. | The surface is relatively smooth and usually requires little surface treatment unless to enhance appearance or corrosion resistance. |

| Production Cost | The initial mold cost is relatively high, but small batches and complex-shaped parts can be manufactured more economically. | Suitable for large-scale production. After mold costs are amortized, the unit cost becomes relatively low. |

What Grade Aluminum for Stamping?

- 3003 Aluminum Alloy: This is a commonly used aluminum alloy with good formability and excellent corrosion resistance, suitable for various stamping applications such as food packaging, appliance components, etc.

- 1100 Aluminum Alloy: This alloy is mainly used for applications requiring high ductility and good formability, making it ideal for lightweight stamped parts.

- 5052 Aluminum Alloy: Known for its excellent corrosion resistance and strength, it is used for stamped parts that require higher strength and corrosion resistance, such as automotive and marine components.