Aluminum Disc

Aluminum circle disc is a circular metal material made of aluminum alloy, with common diameters ranging from 10 to 3000 millimeters, covering multiple alloy series such as 1-series, 3-series, and 5-series. It is mainly used in the fields of electronics, daily chemicals, pharmaceuticals, education, and automotive parts. This product is processed by casting, rolling, cold rolling, and other techniques, featuring corrosion resistance and excellent electrical conductivity. It is widely used in the manufacture of cookware, capacitor housings, traffic signs, and aerospace equipment components.

Aluminum circle disc, also known as aluminum round billet, aluminum gasket, or aluminum blank, refers to circular sheet materials processed from aluminum plates or aluminum coils through stamping, turning, or laser cutting. It is a very common and important basic component in many industrial fields and daily products.

Aluminum discs are used in electronics, daily chemicals, medicine, culture and education, and auto parts. Electrical appliances, thermal insulation, machinery manufacturing, automobiles, aerospace, military industry, molds, construction, printing and other industries. Kitchenware such as non-stick pans, pressure cookers, and hardware such as lampshades, water heater shells, and stretch tanks are among the most widely used aluminum alloy sheet and strip deep-processing products.

Aluminum discs are products of aluminum plates that have been deeply processed. Hot-rolled aluminum discs have the advantages of good heat dissipation, good conductivity, corrosion resistance, light material, and long service life.

Haomei Aluminum Co., Ltd. is a professional aluminum disc manufacturer that has become a leading manufacturer in India, United Arab Emirates, Thailand, Indonesia, Ethiopia, Kenya, Burkina Faso, Ghana, Angola, Morocco, Colombia, Chile, Bolivia, Panama, the United Kingdom, etc. Available in more than 160 countries.

Specification of Haomei Aluminum Circle Discs

| Category | Specification |

| Alloy | 1050 / 1060 / 3003 / 5052 / 6061 |

| Thickness | 0.250" / 0.375" / 0.500" / 0.750" / 1.000" |

| Diameter | 2" / 3" / 4" / 5" / 6" / 8" / 12" / 20" |

| Temper | O (soft, suitable for deep drawing) / H (hard, high strength) |

| Tolerance | Within allowable range for diameter and thickness |

| Surface Finish | Mill Finish / Bright / Anodizing Quality / PE or PVC Coating / Non-stick Coating |

| Production Method | Direct Casting + Hot Rolling / Continuous Cast & Roll (10"–60") |

Aluminum Circle and Disc Classification

Aluminum Circle and Disc Classification by Alloy

1000 series 3000 series 5000 series 8000 series 6000 series

-

Aluminum circle and disc of 1000 series

Alloys: 1050, 1060, 1070, 1100

Performance characteristics: Excellent formability, high reflectivity, stable and high surface anodization performance.

Application: Ordinary cookware, extruded pot lids, aluminum pots, lighting accessories, downlights, lampshades for street lamps, traffic signs, etc.

1060 Aluminum Disc Circle 1070 Aluminum Disc Circle 1050 Aluminum Disc Circle 1100 Aluminum Disc Circle

-

Aluminum circle and disc of 3000 series

Alloys: 3003, 3004, 3105

Performance characteristics: Excellent formability, high elongation, can be used for deep drawing processing, smooth surface, high reflectivity.

Application: High-end cookware, non-stick pans, pressure cookers, lighting accessories, street lamp shades, signs and building materials, etc.

3003 Aluminum Disc Circle 3005 Aluminum Circle Disc 3105 Aluminum Circle Disc

-

Aluminum circle and disc of 5000 series

Alloys: 5052

Performance characteristics: low density, light weight, high elongation, good fatigue strength, and high surface finish.

Application: High-end cookware, pressure vessels, pressure cookers, etc.

-

Aluminum circle and disc of 8000 series

Alloys: 8011

Performance characteristics: Excellent anodizing effect, stable performance, and high surface quality.

Application: Advanced cookware: Pearl anodized cookware can be made.

-

Aluminum circle and disc of 6000 series

Among the 6000 series aluminum discs, the most commonly used is 6061 aluminum disc.

Aluminum Circle Disc Surface Finishing Options

Anodized Aluminium Circle Disc

- Anodized aluminium circles are treated via electrochemical anodizing to form a protective oxide layer.

- This treatment improves corrosion resistance, surface hardness, and provides options for coloring.

- Commonly used for decorative panels, signage, cookware, and lighting housings.

Polished Aluminium Circle Disc

- Polished aluminium circles are mechanically polished to achieve a smooth and shiny surface.

- This enhances visual appeal and gives a reflective finish.

- Applications include decorative trims, signage, electronics housings, and displays.

Mirror Polished Aluminium Circle Disc

- Mirror polished aluminium circles are polished to achieve a mirror-like reflective surface.

- This provides maximum reflectivity and a premium aesthetic finish.

- Used in mirrors, decorative panels, reflectors, and high-end appliances.

Brushed Aluminium Circle Disc

- Brushed aluminium circles feature a uniform linear texture created by mechanical brushing.

- They reduce visible fingerprints and scratches while providing a modern look.

- Common in appliances, furniture panels, architectural cladding, and electronics.

Embossed Aluminium Circle Disc

- Embossed aluminium circles have textured surfaces created via embossing.

- They offer decorative patterns, anti-slip properties, or functional textures.

- Used for ceiling panels, wall decorations, packaging, and industrial components.

PE PVDF Coated Aluminium Circle Disc

- These discs are coated with PE (Polyester) or PVDF (Polyvinylidene Fluoride) for enhanced protection.

- They provide excellent weather resistance, UV stability, and long-term color retention.

- Commonly applied in building facades, roofing panels, signage, and outdoor equipment.

Teflon Coated Aluminium Circle Disc

- Teflon-coated aluminium circles have a non-stick PTFE surface.

- This reduces friction, improves corrosion resistance, and makes cleaning easy.

- Widely used in cookware, chemical equipment, release molds, and industrial processing.

Mill Finish Aluminium Circle Disc

- Mill finish aluminium circles are in their natural rolled state without additional surface finishing.

- They are economical and ideal for further processing or finishing.

- Applications include industrial parts, stamping blanks, and components requiring secondary treatments.

Color Coated Aluminium Circle Disc

- Color coated aluminium circles are finished with paint or powder coating to achieve desired aesthetics.

- They provide decorative appeal and corrosion resistance with a wide range of colors.

- Used in decorative panels, signage, appliances, and automotive trims.

Aluminum Circle and Disc are classified according to processing technology

-

Hot rolled aluminum disc circle

Hot rolling involves heating an aluminum billet or ingot to a high temperature and then passing it through rollers to form it into the desired shape. Hot rolled aluminum disks are commonly used in applications requiring high strength and formability. Hot-rolled aluminum discs have the characteristics of good electrical conductivity, uniform oxidation color, flawless surface, and easy long-term use.

-

Cold Rolled Aluminum Circle

Cold rolling is a process in which aluminum sheet or strip is passed through rollers at room temperature to reduce its thickness and improve its surface finish. Cold rolled aluminum rounds are typically used in applications where precise dimensions, surface quality and flatness are critical. They are commonly used in electronics, signage and construction applications, and cold rolled aluminum sheets do not oxidize well.

-

Aluminum disc circle for deep drawing

Deep drawing is a manufacturing process that uses punches and dies to form sheet metal into the desired shape. Aluminum disks or circles designed specifically for deep drawing have properties suitable for this process, such as high ductility and formability. These discs are often used to produce cookware, auto parts, and other products that require complex shapes.

-

Aluminum disc circle for spinning

Spinning involves spinning an aluminum disc or circle at high speed while forming it relative to a mandrel or forming tool. Aluminum disks designed for spinning typically have good ductility and surface finish that can withstand the spinning process without cracking or deformation. They are commonly used in the production of lampshades, pans and other products.

Aluminum Circle and Disc by application

Aluminum disc circle for traffic sign

When it comes to traffic signs, aluminum discs are often used as the base material for making reflective traffic signs. The circles are often coated with reflective material to ensure visibility and safety on the road, and aluminum's durability and corrosion resistance make it ideal for outdoor applications such as traffic signs.

Aluminum disc circle for cookware

In cookware manufacturing, aluminum discs are used as the primary material for the bottoms or bodies of pots, pans, and other cookware due to their excellent thermal conductivity. These circles are usually stamped or pressed into the desired shape and size before further processing such as anodizing, coating or finishing.

Aluminum disc circle for lighting

Aluminum discs play a vital role in the production of lighting fixtures, especially LED lights. The circles act as heat sinks, ensuring optimal performance and longevity of the lighting system. Aluminum's thermal conductivity makes it an effective material as it helps transfer heat away from the light source quickly.

Aluminum Disc Material Options

Common alloy series for Aluminum Discs include series 1, 3, and 5 (such as 3003, 5052, 6061, etc.).

- Series 1 Pure Aluminum (e.g., 1060, 1100): Aluminum content ≥99%, featuring high plasticity, corrosion resistance, and electrical conductivity. Suitable for deep drawing, commonly used in cookware and lamp housings. For example, 1060 alloy is suitable for making non-stick pans and lamp shades.

- Series 3 Aluminum-Manganese Alloy (e.g., 3003): Manganese added to improve strength and corrosion resistance, excellent formability, commonly used for pressure vessels, automotive parts, and architectural curtain walls. Surface hardness can be enhanced by anodizing.

- Series 5 Aluminum-Magnesium Alloy (e.g., 5052): Outstanding high strength and fatigue resistance, suitable for automotive structural parts and aerospace applications.

| Grade | Characteristics | Main Applications |

| Series 1 (e.g., 1050, 1060) | Pure aluminum, good corrosion resistance, high electrical and thermal conductivity, low strength, good plasticity | Lamps, signs, chemical containers, electrical components |

| Series 3 (e.g., 3003) | Aluminum-manganese alloy, good rust resistance, higher strength than Series 1, good plasticity | Cookware (pots, pans, basins), lamps, home appliance housings |

| Series 5 (e.g., 5052) | Aluminum-magnesium alloy, excellent seawater corrosion resistance, high strength, good fatigue strength | Ship components, automotive parts, aircraft fuel tanks |

| Series 6 (e.g., 6061) | Aluminum-magnesium-silicon alloy, well-rounded performance, high strength, can be heat-treated for strengthening, corrosion resistant | Precision machinery parts, molds, automotive parts (e.g., pistons) |

| Series 8 (e.g., 8011) | Mainly used as aluminum foil raw material, also common in other applications | Bottle caps, heat sinks |

Haomei Aluminum Circle Standard Diameters

2 Inch Aluminum Disc

- Diameter: 2 inches (≈50.8 mm).

- Features: Compact size, lightweight, easy to handle and process.

- Applications: Small cookware, electronic parts, decorative components, and sample testing.

3 Inch Aluminum Disc

- Diameter: 3 inches (≈76.2 mm).

- Features: Slightly larger than 2-inch discs, versatile for small-scale applications.

- Applications: Small kitchen utensils, lighting reflectors, craft projects, and industrial prototypes.

4 Inch Aluminum Disc

- Diameter: 4 inches (≈101.6 mm).

- Features: Moderate size, easy to handle while offering more surface area.

- Applications: Cookware lids, LED lighting components, craft and decoration pieces.

5 Inch Aluminum Disc

- Diameter: 5 inches (≈127 mm).

- Features: Provides a balance between compactness and surface area for processing.

- Applications: Medium-sized cookware, lighting housings, signage components, and industrial parts.

6 Inch Aluminum Disc

- Diameter: 6 inches (≈152.4 mm).

- Features: Popular standard size, suitable for various industrial and domestic uses.

- Applications: Cookware, electrical enclosures, spinning or stamping processes, decorative panels.

8 Inch Aluminum Disc

- Diameter: 8 inches (≈203.2 mm).

- Features: Large enough for medium-to-large applications, stable and easy to process.

- Applications: Larger cookware, lighting reflectors, road signage, and mechanical components.

12 Inch Aluminum Disc

- Diameter: 12 inches (≈304.8 mm).

- Features: Large disc offering extensive surface area for various deep drawing or spinning applications.

- Applications: Cookware, lighting housings, industrial parts, decorative panels, and road signage bases.

20 Inch Aluminum Disc

- Diameter: 20 inches (≈508 mm).

- Features: Very large disc suitable for industrial applications or large-scale decorative uses.

- Applications: Industrial equipment bases, large cookware, road signs, structural parts, and mechanical fabrication.

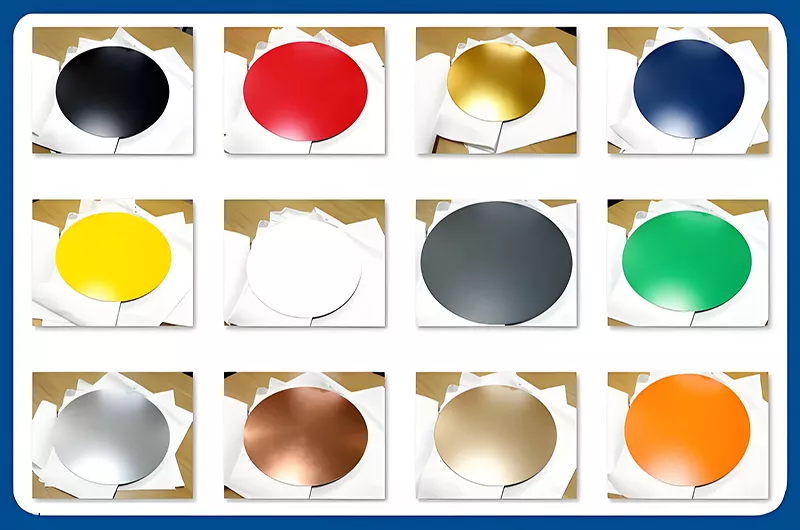

Available Colors for Color-Coated Aluminum Circle Discs

-

Black Aluminum Circle Disc

-

Red Aluminum Circle Disc

-

Gold Aluminum Circle Disc

-

Blue Aluminum Circle Disc

-

Silver Aluminum Circle Disc

-

White Aluminum Circle Disc

-

Gray Aluminum Circle Disc

-

Champagne Aluminum Circle Disc

-

Copper Aluminum Circle

-

Bronze Aluminum Circle Disc

-

Green Aluminum Circle Disc

-

Yellow Aluminum Circle Disc

-

Orange Aluminum Disc

-

Purple Aluminum Circle Disc

Haomei Aluminum Disc Circles in Stock

| Item | Thickness(in) | Diameter(in) | Alloy |

| .250" Thick x 2" Diameter 1050 Aluminum Disc Circle | .250" | 2" | 1050 |

| .250" Thick x 2" Diameter 1060 Aluminum Disc Circle | .250" | 2" | 1060 |

| .250" Thick x 2" Diameter 3003 Aluminum Disc Circle | .250" | 2" | 3003 |

| .250" Thick x 2" Diameter 5052 Aluminum Disc Circle | .250" | 2" | 5052 |

| .250" Thick x 2" Diameter 6061 Aluminum Disc Circle | .250" | 2" | 6061 |

| .250" Thick x 3" Diameter 1050 Aluminum Disc Circle | .250" | 3" | 1050 |

| .250" Thick x 3" Diameter 1060 Aluminum Disc Circle | .250" | 3" | 1060 |

| .250" Thick x 3" Diameter 3003 Aluminum Disc Circle | .250" | 3" | 3003 |

| .250" Thick x 3" Diameter 5052 Aluminum Disc Circle | .250" | 3" | 5052 |

| .250" Thick x 3" Diameter 6061 Aluminum Disc Circle | .250" | 3" | 6061 |

| .250" Thick x 4" Diameter 1050 Aluminum Disc Circle | .250" | 4" | 1050 |

| .250" Thick x 4" Diameter 1060 Aluminum Disc Circle | .250" | 4" | 1060 |

| .250" Thick x 4" Diameter 3003 Aluminum Disc Circle | .250" | 4" | 3003 |

| .250" Thick x 4" Diameter 5052 Aluminum Disc Circle | .250" | 4" | 5052 |

| .250" Thick x 4" Diameter 6061 Aluminum Disc Circle | .250" | 4" | 6061 |

| .250" Thick x 5" Diameter 1050 Aluminum Disc Circle | .250" | 5" | 1050 |

| .250" Thick x 5" Diameter 1060 Aluminum Disc Circle | .250" | 5" | 1060 |

| .250" Thick x 5" Diameter 3003 Aluminum Disc Circle | .250" | 5" | 3003 |

| .250" Thick x 5" Diameter 5052 Aluminum Disc Circle | .250" | 5" | 5052 |

| .250" Thick x 5" Diameter 6061 Aluminum Disc Circle | .250" | 5" | 6061 |

| .250" Thick x 6" Diameter 1050 Aluminum Disc Circle | .250" | 6" | 1050 |

| .250" Thick x 6" Diameter 1060 Aluminum Disc Circle | .250" | 6" | 1060 |

| .250" Thick x 6" Diameter 3003 Aluminum Disc Circle | .250" | 6" | 3003 |

| .250" Thick x 6" Diameter 5052 Aluminum Disc Circle | .250" | 6" | 5052 |

| .250" Thick x 6" Diameter 6061 Aluminum Disc Circle | .250" | 6" | 6061 |

| .250" Thick x 8" Diameter 1050 Aluminum Disc Circle | .250" | 8" | 1050 |

| .250" Thick x 8" Diameter 1060 Aluminum Disc Circle | .250" | 8" | 1060 |

| .250" Thick x 8" Diameter 3003 Aluminum Disc Circle | .250" | 8" | 3003 |

| .250" Thick x 8" Diameter 5052 Aluminum Disc Circle | .250" | 8" | 5052 |

| .250" Thick x 8" Diameter 6061 Aluminum Disc Circle | .250" | 8" | 6061 |

| .250" Thick x 12" Diameter 1050 Aluminum Disc Circle | .250" | 12" | 1050 |

| .250" Thick x 12" Diameter 1060 Aluminum Disc Circle | .250" | 12" | 1060 |

| .250" Thick x 12" Diameter 3003 Aluminum Disc Circle | .250" | 12" | 3003 |

| .250" Thick x 12" Diameter 5052 Aluminum Disc Circle | .250" | 12" | 5052 |

| .250" Thick x 12" Diameter 6061 Aluminum Disc Circle | .250" | 12" | 6061 |

| .250" Thick x 20" Diameter 1050 Aluminum Disc Circle | .250" | 20" | 1050 |

| .250" Thick x 20" Diameter 1060 Aluminum Disc Circle | .250" | 20" | 1060 |

| .250" Thick x 20" Diameter 3003 Aluminum Disc Circle | .250" | 20" | 3003 |

| .250" Thick x 20" Diameter 5052 Aluminum Disc Circle | .250" | 20" | 5052 |

| .250" Thick x 20" Diameter 6061 Aluminum Disc Circle | .250" | 20" | 6061 |

| .375" Thick x 2" Diameter 1050 Aluminum Disc Circle | .375" | 2" | 1050 |

| .375" Thick x 2" Diameter 1060 Aluminum Disc Circle | .375" | 2" | 1060 |

| .375" Thick x 2" Diameter 3003 Aluminum Disc Circle | .375" | 2" | 3003 |

| .375" Thick x 2" Diameter 5052 Aluminum Disc Circle | .375" | 2" | 5052 |

| .375" Thick x 2" Diameter 6061 Aluminum Disc Circle | .375" | 2" | 6061 |

| .375" Thick x 3" Diameter 1050 Aluminum Disc Circle | .375" | 3" | 1050 |

| .375" Thick x 3" Diameter 1060 Aluminum Disc Circle | .375" | 3" | 1060 |

| .375" Thick x 3" Diameter 3003 Aluminum Disc Circle | .375" | 3" | 3003 |

| .375" Thick x 3" Diameter 5052 Aluminum Disc Circle | .375" | 3" | 5052 |

| .375" Thick x 3" Diameter 6061 Aluminum Disc Circle | .375" | 3" | 6061 |

| .375" Thick x 4" Diameter 1050 Aluminum Disc Circle | .375" | 4" | 1050 |

| .375" Thick x 4" Diameter 1060 Aluminum Disc Circle | .375" | 4" | 1060 |

| .375" Thick x 4" Diameter 3003 Aluminum Disc Circle | .375" | 4" | 3003 |

| .375" Thick x 4" Diameter 5052 Aluminum Disc Circle | .375" | 4" | 5052 |

| .375" Thick x 4" Diameter 6061 Aluminum Disc Circle | .375" | 4" | 6061 |

| .375" Thick x 5" Diameter 1050 Aluminum Disc Circle | .375" | 5" | 1050 |

| .375" Thick x 5" Diameter 1060 Aluminum Disc Circle | .375" | 5" | 1060 |

| .375" Thick x 5" Diameter 3003 Aluminum Disc Circle | .375" | 5" | 3003 |

| .375" Thick x 5" Diameter 5052 Aluminum Disc Circle | .375" | 5" | 5052 |

| .375" Thick x 5" Diameter 6061 Aluminum Disc Circle | .375" | 5" | 6061 |

| .375" Thick x 6" Diameter 1050 Aluminum Disc Circle | .375" | 6" | 1050 |

| .375" Thick x 6" Diameter 1060 Aluminum Disc Circle | .375" | 6" | 1060 |

| .375" Thick x 6" Diameter 3003 Aluminum Disc Circle | .375" | 6" | 3003 |

| .375" Thick x 6" Diameter 5052 Aluminum Disc Circle | .375" | 6" | 5052 |

| .375" Thick x 6" Diameter 6061 Aluminum Disc Circle | .375" | 6" | 6061 |

| .375" Thick x 8" Diameter 1050 Aluminum Disc Circle | .375" | 8" | 1050 |

| .375" Thick x 8" Diameter 1060 Aluminum Disc Circle | .375" | 8" | 1060 |

| .375" Thick x 8" Diameter 3003 Aluminum Disc Circle | .375" | 8" | 3003 |

| .375" Thick x 8" Diameter 5052 Aluminum Disc Circle | .375" | 8" | 5052 |

| .375" Thick x 8" Diameter 6061 Aluminum Disc Circle | .375" | 8" | 6061 |

| .375" Thick x 12" Diameter 1050 Aluminum Disc Circle | .375" | 12" | 1050 |

| .375" Thick x 12" Diameter 1060 Aluminum Disc Circle | .375" | 12" | 1060 |

| .375" Thick x 12" Diameter 3003 Aluminum Disc Circle | .375" | 12" | 3003 |

| .375" Thick x 12" Diameter 5052 Aluminum Disc Circle | .375" | 12" | 5052 |

| .375" Thick x 12" Diameter 6061 Aluminum Disc Circle | .375" | 12" | 6061 |

| .375" Thick x 20" Diameter 1050 Aluminum Disc Circle | .375" | 20" | 1050 |

| .375" Thick x 20" Diameter 1060 Aluminum Disc Circle | .375" | 20" | 1060 |

| .375" Thick x 20" Diameter 3003 Aluminum Disc Circle | .375" | 20" | 3003 |

| .375" Thick x 20" Diameter 5052 Aluminum Disc Circle | .375" | 20" | 5052 |

| .375" Thick x 20" Diameter 6061 Aluminum Disc Circle | .375" | 20" | 6061 |

| .500" Thick x 2" Diameter 1050 Aluminum Disc Circle | .500" | 2" | 1050 |

| .500" Thick x 2" Diameter 1060 Aluminum Disc Circle | .500" | 2" | 1060 |

| .500" Thick x 2" Diameter 3003 Aluminum Disc Circle | .500" | 2" | 3003 |

| .500" Thick x 2" Diameter 5052 Aluminum Disc Circle | .500" | 2" | 5052 |

| .500" Thick x 2" Diameter 6061 Aluminum Disc Circle | .500" | 2" | 6061 |

| .500" Thick x 3" Diameter 1050 Aluminum Disc Circle | .500" | 3" | 1050 |

| .500" Thick x 3" Diameter 1060 Aluminum Disc Circle | .500" | 3" | 1060 |

| .500" Thick x 3" Diameter 3003 Aluminum Disc Circle | .500" | 3" | 3003 |

| .500" Thick x 3" Diameter 5052 Aluminum Disc Circle | .500" | 3" | 5052 |

| .500" Thick x 3" Diameter 6061 Aluminum Disc Circle | .500" | 3" | 6061 |

| .500" Thick x 4" Diameter 1050 Aluminum Disc Circle | .500" | 4" | 1050 |

| .500" Thick x 4" Diameter 1060 Aluminum Disc Circle | .500" | 4" | 1060 |

| .500" Thick x 4" Diameter 3003 Aluminum Disc Circle | .500" | 4" | 3003 |

| .500" Thick x 4" Diameter 5052 Aluminum Disc Circle | .500" | 4" | 5052 |

| .500" Thick x 4" Diameter 6061 Aluminum Disc Circle | .500" | 4" | 6061 |

| .500" Thick x 5" Diameter 1050 Aluminum Disc Circle | .500" | 5" | 1050 |

| .500" Thick x 5" Diameter 1060 Aluminum Disc Circle | .500" | 5" | 1060 |

| .500" Thick x 5" Diameter 3003 Aluminum Disc Circle | .500" | 5" | 3003 |

| .500" Thick x 5" Diameter 5052 Aluminum Disc Circle | .500" | 5" | 5052 |

| .500" Thick x 5" Diameter 6061 Aluminum Disc Circle | .500" | 5" | 6061 |

| .500" Thick x 6" Diameter 1050 Aluminum Disc Circle | .500" | 6" | 1050 |

| .500" Thick x 6" Diameter 1060 Aluminum Disc Circle | .500" | 6" | 1060 |

| .500" Thick x 6" Diameter 3003 Aluminum Disc Circle | .500" | 6" | 3003 |

| .500" Thick x 6" Diameter 5052 Aluminum Disc Circle | .500" | 6" | 5052 |

| .500" Thick x 6" Diameter 6061 Aluminum Disc Circle | .500" | 6" | 6061 |

| .500" Thick x 8" Diameter 1050 Aluminum Disc Circle | .500" | 8" | 1050 |

| .500" Thick x 8" Diameter 1060 Aluminum Disc Circle | .500" | 8" | 1060 |

| .500" Thick x 8" Diameter 3003 Aluminum Disc Circle | .500" | 8" | 3003 |

| .500" Thick x 8" Diameter 5052 Aluminum Disc Circle | .500" | 8" | 5052 |

| .500" Thick x 8" Diameter 6061 Aluminum Disc Circle | .500" | 8" | 6061 |

| .500" Thick x 12" Diameter 1050 Aluminum Disc Circle | .500" | 12" | 1050 |

| .500" Thick x 12" Diameter 1060 Aluminum Disc Circle | .500" | 12" | 1060 |

| .500" Thick x 12" Diameter 3003 Aluminum Disc Circle | .500" | 12" | 3003 |

| .500" Thick x 12" Diameter 5052 Aluminum Disc Circle | .500" | 12" | 5052 |

| .500" Thick x 12" Diameter 6061 Aluminum Disc Circle | .500" | 12" | 6061 |

| .500" Thick x 20" Diameter 1050 Aluminum Disc Circle | .500" | 20" | 1050 |

| .500" Thick x 20" Diameter 1060 Aluminum Disc Circle | .500" | 20" | 1060 |

| .500" Thick x 20" Diameter 3003 Aluminum Disc Circle | .500" | 20" | 3003 |

| .500" Thick x 20" Diameter 5052 Aluminum Disc Circle | .500" | 20" | 5052 |

| .500" Thick x 20" Diameter 6061 Aluminum Disc Circle | .500" | 20" | 6061 |

| .750" Thick x 2" Diameter 1050 Aluminum Disc Circle | .750" | 2" | 1050 |

| .750" Thick x 2" Diameter 1060 Aluminum Disc Circle | .750" | 2" | 1060 |

| .750" Thick x 2" Diameter 3003 Aluminum Disc Circle | .750" | 2" | 3003 |

| .750" Thick x 2" Diameter 5052 Aluminum Disc Circle | .750" | 2" | 5052 |

| .750" Thick x 2" Diameter 6061 Aluminum Disc Circle | .750" | 2" | 6061 |

| .750" Thick x 3" Diameter 1050 Aluminum Disc Circle | .750" | 3" | 1050 |

| .750" Thick x 3" Diameter 1060 Aluminum Disc Circle | .750" | 3" | 1060 |

| .750" Thick x 3" Diameter 3003 Aluminum Disc Circle | .750" | 3" | 3003 |

| .750" Thick x 3" Diameter 5052 Aluminum Disc Circle | .750" | 3" | 5052 |

| .750" Thick x 3" Diameter 6061 Aluminum Disc Circle | .750" | 3" | 6061 |

| .750" Thick x 4" Diameter 1050 Aluminum Disc Circle | .750" | 4" | 1050 |

| .750" Thick x 4" Diameter 1060 Aluminum Disc Circle | .750" | 4" | 1060 |

| .750" Thick x 4" Diameter 3003 Aluminum Disc Circle | .750" | 4" | 3003 |

| .750" Thick x 4" Diameter 5052 Aluminum Disc Circle | .750" | 4" | 5052 |

| .750" Thick x 4" Diameter 6061 Aluminum Disc Circle | .750" | 4" | 6061 |

| .750" Thick x 5" Diameter 1050 Aluminum Disc Circle | .750" | 5" | 1050 |

| .750" Thick x 5" Diameter 1060 Aluminum Disc Circle | .750" | 5" | 1060 |

| .750" Thick x 5" Diameter 3003 Aluminum Disc Circle | .750" | 5" | 3003 |

| .750" Thick x 5" Diameter 5052 Aluminum Disc Circle | .750" | 5" | 5052 |

| .750" Thick x 5" Diameter 6061 Aluminum Disc Circle | .750" | 5" | 6061 |

| .750" Thick x 6" Diameter 1050 Aluminum Disc Circle | .750" | 6" | 1050 |

| .750" Thick x 6" Diameter 1060 Aluminum Disc Circle | .750" | 6" | 1060 |

| .750" Thick x 6" Diameter 3003 Aluminum Disc Circle | .750" | 6" | 3003 |

| .750" Thick x 6" Diameter 5052 Aluminum Disc Circle | .750" | 6" | 5052 |

| .750" Thick x 6" Diameter 6061 Aluminum Disc Circle | .750" | 6" | 6061 |

| .750" Thick x 8" Diameter 1050 Aluminum Disc Circle | .750" | 8" | 1050 |

| .750" Thick x 8" Diameter 1060 Aluminum Disc Circle | .750" | 8" | 1060 |

| .750" Thick x 8" Diameter 3003 Aluminum Disc Circle | .750" | 8" | 3003 |

| .750" Thick x 8" Diameter 5052 Aluminum Disc Circle | .750" | 8" | 5052 |

| .750" Thick x 8" Diameter 6061 Aluminum Disc Circle | .750" | 8" | 6061 |

| .750" Thick x 12" Diameter 1050 Aluminum Disc Circle | .750" | 12" | 1050 |

| .750" Thick x 12" Diameter 1060 Aluminum Disc Circle | .750" | 12" | 1060 |

| .750" Thick x 12" Diameter 3003 Aluminum Disc Circle | .750" | 12" | 3003 |

| .750" Thick x 12" Diameter 5052 Aluminum Disc Circle | .750" | 12" | 5052 |

| .750" Thick x 12" Diameter 6061 Aluminum Disc Circle | .750" | 12" | 6061 |

| .750" Thick x 20" Diameter 1050 Aluminum Disc Circle | .750" | 20" | 1050 |

| .750" Thick x 20" Diameter 1060 Aluminum Disc Circle | .750" | 20" | 1060 |

| .750" Thick x 20" Diameter 3003 Aluminum Disc Circle | .750" | 20" | 3003 |

| .750" Thick x 20" Diameter 5052 Aluminum Disc Circle | .750" | 20" | 5052 |

| .750" Thick x 20" Diameter 6061 Aluminum Disc Circle | .750" | 20" | 6061 |

| 1.000" Thick x 2" Diameter 1050 Aluminum Disc Circle | 1.000" | 2" | 1050 |

| 1.000" Thick x 2" Diameter 1060 Aluminum Disc Circle | 1.000" | 2" | 1060 |

| 1.000" Thick x 2" Diameter 3003 Aluminum Disc Circle | 1.000" | 2" | 3003 |

| 1.000" Thick x 2" Diameter 5052 Aluminum Disc Circle | 1.000" | 2" | 5052 |

| 1.000" Thick x 2" Diameter 6061 Aluminum Disc Circle | 1.000" | 2" | 6061 |

| 1.000" Thick x 3" Diameter 1050 Aluminum Disc Circle | 1.000" | 3" | 1050 |

| 1.000" Thick x 3" Diameter 1060 Aluminum Disc Circle | 1.000" | 3" | 1060 |

| 1.000" Thick x 3" Diameter 3003 Aluminum Disc Circle | 1.000" | 3" | 3003 |

| 1.000" Thick x 3" Diameter 5052 Aluminum Disc Circle | 1.000" | 3" | 5052 |

| 1.000" Thick x 3" Diameter 6061 Aluminum Disc Circle | 1.000" | 3" | 6061 |

| 1.000" Thick x 4" Diameter 1050 Aluminum Disc Circle | 1.000" | 4" | 1050 |

| 1.000" Thick x 4" Diameter 1060 Aluminum Disc Circle | 1.000" | 4" | 1060 |

| 1.000" Thick x 4" Diameter 3003 Aluminum Disc Circle | 1.000" | 4" | 3003 |

| 1.000" Thick x 4" Diameter 5052 Aluminum Disc Circle | 1.000" | 4" | 5052 |

| 1.000" Thick x 4" Diameter 6061 Aluminum Disc Circle | 1.000" | 4" | 6061 |

| 1.000" Thick x 5" Diameter 1050 Aluminum Disc Circle | 1.000" | 5" | 1050 |

| 1.000" Thick x 5" Diameter 1060 Aluminum Disc Circle | 1.000" | 5" | 1060 |

| 1.000" Thick x 5" Diameter 3003 Aluminum Disc Circle | 1.000" | 5" | 3003 |

| 1.000" Thick x 5" Diameter 5052 Aluminum Disc Circle | 1.000" | 5" | 5052 |

| 1.000" Thick x 5" Diameter 6061 Aluminum Disc Circle | 1.000" | 5" | 6061 |

| 1.000" Thick x 6" Diameter 1050 Aluminum Disc Circle | 1.000" | 6" | 1050 |

| 1.000" Thick x 6" Diameter 1060 Aluminum Disc Circle | 1.000" | 6" | 1060 |

| 1.000" Thick x 6" Diameter 3003 Aluminum Disc Circle | 1.000" | 6" | 3003 |

| 1.000" Thick x 6" Diameter 5052 Aluminum Disc Circle | 1.000" | 6" | 5052 |

| 1.000" Thick x 6" Diameter 6061 Aluminum Disc Circle | 1.000" | 6" | 6061 |

| 1.000" Thick x 8" Diameter 1050 Aluminum Disc Circle | 1.000" | 8" | 1050 |

| 1.000" Thick x 8" Diameter 1060 Aluminum Disc Circle | 1.000" | 8" | 1060 |

| 1.000" Thick x 8" Diameter 3003 Aluminum Disc Circle | 1.000" | 8" | 3003 |

| 1.000" Thick x 8" Diameter 5052 Aluminum Disc Circle | 1.000" | 8" | 5052 |

| 1.000" Thick x 8" Diameter 6061 Aluminum Disc Circle | 1.000" | 8" | 6061 |

| 1.000" Thick x 12" Diameter 1050 Aluminum Disc Circle | 1.000" | 12" | 1050 |

| 1.000" Thick x 12" Diameter 1060 Aluminum Disc Circle | 1.000" | 12" | 1060 |

| 1.000" Thick x 12" Diameter 3003 Aluminum Disc Circle | 1.000" | 12" | 3003 |

| 1.000" Thick x 12" Diameter 5052 Aluminum Disc Circle | 1.000" | 12" | 5052 |

| 1.000" Thick x 12" Diameter 6061 Aluminum Disc Circle | 1.000" | 12" | 6061 |

| 1.000" Thick x 20" Diameter 1050 Aluminum Disc Circle | 1.000" | 20" | 1050 |

| 1.000" Thick x 20" Diameter 1060 Aluminum Disc Circle | 1.000" | 20" | 1060 |

| 1.000" Thick x 20" Diameter 3003 Aluminum Disc Circle | 1.000" | 20" | 3003 |

| 1.000" Thick x 20" Diameter 5052 Aluminum Disc Circle | 1.000" | 20" | 5052 |

| 1.000" Thick x 20" Diameter 6061 Aluminum Disc Circle | 1.000" | 20" | 6061 |

Aluminum Disc Characteristics

- Lightweight: Aluminum has a low density of about 2.7 g/cm³, less than one-third of steel, making it ideal for applications where weight reduction is important.

- Corrosion Resistance: Aluminum naturally forms a dense oxide layer on its surface, providing excellent corrosion resistance, especially in atmospheric and many chemical environments.

- Electrical and Thermal Conductivity: Conductivity is about 60% that of copper, with good thermal conductivity, commonly used in heat dissipation components.

- Machinability: Easy to perform stamping, stretching, turning, drilling, bending, and other mechanical processing.

- Non-Magnetic: A non-magnetic material, suitable for electronics and precision instruments.

- Good Plasticity: Can be formed into various shapes such as housings for cookware or lamps through stretching and other processes.

- Aesthetic: Surface can be polished, painted, anodized, etc., to achieve different colors and textures.

- Recyclable: 100% recyclable, environmentally friendly, and cost-effective.

Aluminum Circle and Disc Applications

Aluminum discs are usually the initial blanks for products and require subsequent deep processing. Aluminum Circles and Discs are used in cookware, capacitor housings, traffic signs, aerospace components, and machinery manufacturing.

- Cookware Industry: The primary application area. Used as blanks for pots, kettles, pans, boxes, and other tableware, shaped by deep drawing.

- Lighting Industry: For making lampshades, reflectors, lamp bases, etc.

- Electronics and Electrical: Used for capacitor housings, heat sinks, motor end covers, electronic shielding covers, etc.

- Automotive Industry: Manufacturing car emblems, sensor gaskets, clutch plates, piston blanks, etc.

- Packaging Industry: Making bottle caps, cosmetic container lids, beverage can lids, etc.

- Signage Industry: Producing various nameplates, badges, medals, etc.

- Machinery Industry: Used as blanks for precision parts such as gaskets, flanges, and gear blanks.

Cookware Aluminum Circle Disc (Aluminum Disc for Cookware)

- Features: Deep drawing and thermal conductivity

- Description: Mainly used for manufacturing pots, kettles, and other cookware. Made from high-purity aluminum alloys (e.g., 1050, 1060, 3003), offering excellent deep drawing performance and good thermal conductivity. Surface must be clean to ensure adhesion of non-stick coatings.

Lighting Aluminium Circle Disc (Aluminum Disc for Lighting)

- Features: Surface reflectivity and formability

- Description: Used for making LED lampshades and reflectors. Usually pure aluminum or soft aluminum alloys (e.g., 1050-O, 1100-O), highly ductile and easy to spin or deep draw. Surface can be mirror polished or anodized to achieve high reflectivity.

Aluminum Circle Disc for Road Sign

- Features: Weather resistance and coating adhesion

- Description: Used as the base material for road traffic signs. Typically high-strength, corrosion-resistant alloys (e.g., 3003, 5052) in a semi-hard state (H14/H16) to maintain flatness and wind load resistance. Surface must be treated to perfectly adhere to paint and reflective films.

Spinning Aluminium Circle Disc

- Features: Extremely high plasticity (soft state)

- Description: Prepared specifically for metal spinning processes. Must use O-state (soft) pure aluminum or aluminum-manganese alloys (e.g., 1050-O, 3003-O) with excellent ductility, capable of large plastic deformation during rotation without cracking, for making complex curved parts.

Aluminum Slug

- Features: Cold forging blank, precise weight

- Description: A cylindrical blank made by cold extrusion for forging processes. Not a regular punched disc. Requires very high dimensional and weight accuracy, used as the initial material for high-strength, complex structural parts (e.g., automotive pistons).

Electronics and Electrical

Capacitor aluminum shell blanks use Series 1 alloys for high conductivity; LED lamp housings use 3003 alloy for both heat dissipation and aesthetics.

Automotive Industry

Series 5 alloy discs are used for lightweight structural parts, such as engine covers, achieving weight reduction of over 30%.

Packaging Sector

8011 alloy discs are used for aerosol can sealing, with thickness 0.2–0.3mm, FDA certified to ensure food contact safety.

Aluminum Circle and Disc Application Specification Parameter Table

| Application | Alloy | Temper | Thickness | Width |

| Non-Stick aluminum circle/disk/disc | 1050, 1060, 1100, 3003 | O, H14 | 0.5mm to 6.0mm | 100mm to 600mm |

| Bread mold aluminium circle | 1050, 1060, 1100 | O, H12 | 0.5mm to 3.0mm | 100mm to 500mm |

| Aluminum circle for food cans | 3004, 3104, 5052 | H14, H18 | 0.2mm to 2.0mm | 100mm to 600mm |

| Spinning Aluminium disc circle for Lampshade | 1050, 1060, 1070, 3003 | O, H14 | 0.5mm to 3.0mm | 100mm to 800mm |

| reflective circle aluminum highway warn | 1050, 1060, 3003 | H14, H24 | 1.0mm to 3.0mm | 100mm to 1200mm |

| Aluminum discs for pharmaceutical cans | 3004, 3104, 5052 | H14, H18 | 0.2mm to 2.0mm | 100mm to 600mm |

| aluminum circle for punching | 1050, 1060, 1100, 3003 | O, H12, H14 | 0.5mm to 3.0mm | 100mm to 1200mm |

The choice of aluminum alloy discs for different applications is driven by the specific properties required for each use case. Here’s a breakdown of why specific alloys are chosen for the corresponding applications:

Non-Stick Aluminum Circle/Disk/Disc

Alloy: 1050, 1060, 1100, 3003

Reasons:

1050, 1060, 1100: High purity aluminum, excellent formability, good thermal conductivity which is essential for even heating in cookware.

3003: Slightly stronger than pure aluminum, good corrosion resistance, and formability. Suitable for non-stick coating applications as it can withstand the coating process.

Bread Mold Aluminium Circle

Alloy: 1050, 1060, 1100

Reasons:

High purity aluminum alloys like 1050, 1060, and 1100 provide excellent thermal conductivity for even baking. These alloys are also easy to form and mold into complex shapes required for bread molds.

Aluminum Circle for Food Cans

Alloy: 3004, 3104, 5052

Reasons:

3004, 3104: Excellent formability and strength, good corrosion resistance, and suitable for deep drawing processes used in can manufacturing.

5052: High strength, excellent corrosion resistance, and suitable for containers that require higher durability and resistance to acidic food contents.

Spinning Aluminum Disc Circle for Lampshade

Alloy: 1050, 1060, 1070, 3003

Reasons:

These alloys have high formability and are easily spun into complex shapes. They also provide a good surface finish and can be anodized for aesthetic purposes.

Reflective Circle Aluminum Highway Warning Signs

Alloy: 1050, 1060, 3003

Reasons:

1050, 1060: High reflectivity, excellent corrosion resistance, and suitable for outdoor use.

3003: Provides a good balance of strength and formability, with good corrosion resistance, making it suitable for highway signs that require durability and visibility.

Aluminum Discs for Pharmaceutical Cans

Alloy: 3004, 3104, 5052

Reasons:

3004, 3104: Good formability and strength, which are necessary for the manufacturing of pharmaceutical cans that require precision and reliability.

5052: High strength and excellent corrosion resistance, important for ensuring the integrity and safety of pharmaceutical products.

Aluminum Circle for Punching

Alloy: 1050, 1060, 1100, 3003

Reasons:

These alloys are chosen for their excellent formability, ease of punching and cutting, and good corrosion resistance. They are also cost-effective for mass production of punched components.

What is a good Aluminum Circle and Disc blank?

- Surface quality: High-quality aluminum wafers have no defects such as deformation, scratches, cracks or yellow spots. The surface color is uniform and there is no color difference.

- Chemical composition: The chemical composition should comply with relevant standards and can be detected by a professional spectrum analyzer and compared with standards such as GB/T3880-2012 or ASTM B209. Ensure that various chemical elements are within the scope of standard requirements.

- Mechanical properties: Test the tensile strength and mechanical properties of the aluminum circle through a tensile testing machine to ensure that it meets the standard requirements. This reduces breakage during the stamping and spinning processes and avoids wasting time and material costs.

- Particle size detection: The control of grain size can vary according to the manufacturer's requirements. Most factories control the grain size above level two, while some large factories require level one. This helps improve the yield during aluminum disc production and ensures product quality.

Haomei Aluminum Circle and Disc Quality Assurance

- Wide range of size selection.

- Excellent drawing and spinning quality.

- Excellent surface quality, clean, smooth and scratch-free.

- The cutting edges are neat and burr-free.

- The packaging is well protected.

What quality problems may you encounter during use of Aluminum Circle and Disc?

- Spin cracks: During the spinning or drawing process, aluminum discs may have cracks or edge cracks due to sand, impurities or metal embedding. These cracks not only affect the appearance and quality of the product, but also lead to waste during the production process.

- Surface orange peel problem: The surface of some finished pots may not be smooth enough and needs to be polished. This is usually due to the uneven grain size of the aluminum flakes or incomplete processing of the material from the beginning to the end during the production of aluminum discs, which affects the appearance quality of the product.

- Surface oxidation: Although aluminum discs have good anti-rust properties, if they are corroded by rain or moisture during storage or transportation, the surface of the aluminum discs is prone to oxidation. This affects the aesthetics and longevity of the product. Therefore, the packaging must be tight and enough desiccant must be added to prevent the aluminum discs from getting wet.

Aluminum Circle and Disc Packaging and Transportation Precautions

- Can be covered with plastic film and kraft paper according to customer needs.

- Use wooden boxes or wooden pallets to protect products from damage during transportation.

- Packaging customers can choose as per their convenience.

Generally speaking, one package is 2 tons, 1×20′ container is loaded with 18-22 tons, and 1×40′ container is loaded with 20-24 tons.

Aluminum Disc Production Process

- Die Stamping: The most commonly used and most efficient method. Aluminum sheets or coils are rapidly stamped and blanked on a press using molds. Suitable for large-scale production.

- Laser Cutting: Uses a laser cutting machine to cut circular shapes according to programmed paths. Suitable for small batches, multiple varieties, or thicker materials with high precision requirements. Highly flexible with no mold cost.

- Lathe Finishing: CNC lathes are used to machine aluminum rods into discs. Suitable for precision parts requiring extremely high dimensional accuracy, roundness, and flatness.

How to Choose an Aluminum Disc Supplier

- Production Capacity: Confirm whether the supplier has stamping or cutting equipment suitable for your product specifications.

- Material Source: Ensure the source of aluminum is reliable and material quality is stable.

- Quality Control: Check if the supplier has a complete quality inspection system (e.g., dimensional inspection, material reports).

- Sample Confirmation: Always request samples and confirm their quality before mass purchasing.

- After-Sales Service: Choose a supplier who can provide strong technical support and good after-sales service.

Different Types and Names of Aluminum Discs

Aluminum Disc / Aluminum Disk

- Description: Circular sheets stamped or cut from aluminum plates, available in various specifications.

- Applications: Widely used in cookware, utensils, lighting, machinery parts, signage, etc.

Aluminum Circle Disc

- Description: Common standard circular aluminum sheets with high dimensional accuracy and good roundness.

- Applications: Often used in cookware, road signs, decorative parts, and stamped components.

Aluminum Round Disc

- Description: Regular-shaped circular aluminum material; surfaces can be polished, brushed, or anodized.

- Applications: Used in household utensils, lighting equipment, handicrafts, etc.

Aluminum Discs Blank / Blank Aluminium Discs

- Description: Untreated or unprocessed blank discs, convenient for subsequent stamping, spinning, or anodizing.

- Applications: Widely used as raw materials, suitable for secondary processing into various products.

Aluminium Circle Plate

- Description: Thicker circular aluminum plates with high strength and load-bearing capacity.

- Applications: Commonly used in machinery parts, flanges, structural components, etc.

Aluminum Circle Blanks

- Description: Standardized blank discs with neat edges, burr-free, suitable for industrial mass production.

- Applications: Raw material for cookware, lighting, electronic housings, and packaging containers.

Aluminum Round Blanks

- Description: Similar to circle blanks, emphasizing the round contour of the blank product.

- Applications: Used for spinning, stretching, and stamping processes.

Aluminum Round Circle

- Description: Large-diameter discs or ring-shaped aluminum products.

- Applications: Used for decoration, mechanical structural parts, or signage.

Aluminum Sheet Circle

- Description: Directly cut or stamped from aluminum sheets, relatively thin in thickness.

- Applications: Suitable for signage, thin sheet stamping parts, and lightweight decorative components.

Large Aluminum Discs

- Description: Large-sized aluminum discs, with diameters exceeding conventional specifications.

- Applications: Used for road signs, industrial equipment, and large container bottoms.

Round Aluminium Discs / Aluminium Discs Circles

- Description: Common general term for circular discs, can refer to aluminum discs of different specifications and applications.

- Applications: Cookware, lighting, packaging, mechanical processing, and more.

Aluminum Foil Discs

- Description: Thin circular sheets stamped or cut from aluminum foil, extremely thin in thickness.

- Applications: Used for sealing, gaskets, food packaging, and laboratory consumables.

Common Questions About Aluminum Discs

What materials and alloy series are available for aluminum discs?

Haomei Aluminum commonly uses alloy series 1000 (1050, 1060, 1100), 3000 (3003), 5000 (5052), 6000 (6061), etc. Different series have different strength, ductility, and corrosion resistance, and can be selected according to application.

Can you provide aluminum discs with rough edges, smooth edges, or chamfered edges?

Yes. According to customer requirements, we provide:

- Rough-edge discs (direct stamping)

- Smooth-edge discs (trimmed to remove burrs)

- Chamfered-edge discs (edges polished to prevent cutting)

Can aluminum discs be deep drawn or spun?

Yes. Different alloys and temper are suitable for different processes:

- O Temper (soft): Suitable for deep drawing and spinning

- H14 / H18 Hard Temper: Suitable for stamping and forming

What are the packaging and transportation methods?

Typically packaged with moisture-proof plastic film + wooden pallets to prevent scratches or deformation during transport. Custom export packaging is available upon request.

What is the delivery lead time for aluminum discs?

Standard specifications are in stock, with 3–7 days for shipment. Custom specifications depend on production schedules, generally 15–25 days.