Color Coated Aluminum Circle Disc

What is a Color Coated Aluminum Circle?

A color coated aluminum circle is made from high-quality aluminum or aluminum alloy coils/sheets as the base material. After surface pre-treatment, multiple layers of organic color coatings (such as Polyester PE, Fluorocarbon PVDF, etc.) are applied on the surface and cured through a baking process to produce pre-painted circular aluminum blanks.

Color-coated aluminum discs combine the advantages of aluminum's lightweight and excellent formability with the decorative, weather-resistant, and protective properties provided by the coating. The coating is applied before forming, effectively improving production efficiency and ensuring consistent product quality.

Color coated aluminum circles are widely used in cookware manufacturing, lighting fixtures, signage, and decorative applications where both appearance and durability are highly required.

The color-coated aluminum circle disc is protected from environmental factors such as moisture and chemicals, extending its lifespan. The color coating offers a variety of colors and finishes. Color-coated aluminum discs are versatile materials used across various industries, offering both functional and decorative advantages. They combine durability, aesthetic appeal, and protective performance, making them suitable for a wide range of applications.

Color Coated Aluminum Circle Disc Specifications

| Item | Specification |

| Product Name | Color Coated Aluminum Circle Disc |

| Base Material | Aluminum and Aluminum Alloy Coils / Sheets |

| Common Alloys | 1xxx Series (1050 / 1060 / 1100) |

| 3xxx Series (3003 / 3004) | |

| 5xxx Series (5052) | |

| Aluminum Alloy Properties | 1xxx: High purity, excellent formability, corrosion resistance |

| 3xxx: Higher strength and rust resistance | |

| 5xxx: High strength, excellent corrosion resistance | |

| Thickness Range | 0.20 mm – 6.0 mm (commonly 0.2 – 4.0 mm) |

| Diameter Range | 80 mm – 1200 mm |

| Dimensional Tolerance | In accordance with industry standards or customized per customer requirements |

| Temper | O (Annealed), H12, H14, H18 |

| Coating Type | PE (Polyester Coating) |

| PVDF (Fluorocarbon Coating) | |

| Coating Performance | PE: Rich colors, cost-effective, lifespan about 8–15 years |

| PVDF: Weather-resistant, UV resistant, lifespan up to 20–30 years | |

| Color | White, Black, Red, Blue, Silver, Gold, and Custom RAL Colors |

| Surface Finish | Glossy / Matte / Textured |

| Processing Capability | Suitable for stamping, stretching, spinning, and other forming processes |

| Main Applications | Architectural decoration, cookware, lighting, signage, electronics, transportation |

| Supply Form | Discs / Circles |

| Customization Service | Alloy, thickness, diameter, color, and coating can all be customized |

Color Options for Color Coated Aluminum Circle Disc

Color-coated aluminum discs come in a wide range of colors, including red, yellow, green, black, blue, and more. The colored coating on these discs makes them visually appealing and versatile, meeting various aesthetic and decorative needs. They are widely used in various products, particularly in kitchenware.

Color Coated Aluminum Circle Disc Coating Types

Color Coated Aluminum Circle Disc can adopt various surface coating systems depending on different application scenarios, usage environments, and processing requirements. They are widely used in cookware manufacturing, decorative products, and architectural aluminum products. The common coating types and their characteristics are as follows:

PE (Polyester) Coating

PE (Polyester) coating is one of the most widely used types for color coated aluminum circle discs, mainly suitable for indoor use, such as the exterior surface of cookware, kitchenware, and decorative aluminum products.

This coating features good adhesion, formability, and color retention. Under normal usage conditions, its service life can reach 10–15 years, making it a cost-effective coating solution that balances performance and price.

PVDF (Fluorocarbon) Coating

PVDF (Polyvinylidene Fluoride) fluorocarbon coating belongs to the high-end color coating system, known for its excellent weather resistance, UV resistance, and long-term color stability.

This coating is commonly used for outdoor aluminum products, architectural aluminum materials, and high-end cookware aluminum discs that require superior appearance and durability. It is especially suitable for applications exposed to sunlight and complex weather conditions over long periods.

Food-grade / Non-stick Coating (PTFE)

Food-grade coatings are mainly used for cookware-grade aluminum discs. Among them, PTFE (Teflon) non-stick coating is specifically designed for the interior of cookware, significantly reducing food adhesion and improving cooking efficiency and ease of cleaning.

Some food-grade coatings can also be applied to aluminum discs for pot bottoms or lids, with specific configurations customized according to customer product standards and market demands.

Coating Process Description

Color Coated Aluminum Circle Discs usually adopt the roll coating (Roll Coating) process, with the coating applied at the aluminum coil (Color Coated Aluminum Coil) stage, and then the discs are stamped from the coated coil.

This production method ensures uniform coating thickness, stable surface quality, and effectively enhances the consistency and yield of color coated aluminum discs during stamping, drawing, and deep processing.

Coating Type Comparison

| Coating | Warranty Period | Coating Thickness | Applicable Scenarios |

| Polyester PE | 10 years | Single layer 4-20μm, Double layer 25-28μm | Indoor decoration, cookware, small appliances |

| Fluorocarbon PVDF | Longer than PE | Double layer 25-28μm, Triple layer 35-38μm | Outdoor architecture, curtain walls, high-end decoration |

| Epoxy | 5-8 years | 15-25μm | Industrial anti-corrosion, special functional components |

| Anodized | Long-term | 5-20μm | Wear-resistant, electrically and thermally conductive components |

Features of Color Coated Aluminum Circle Disc

- Made with high-quality color coatings, providing uniform and stable colors, available in matte or glossy finishes, with long-lasting appearance and fade resistance.

- Excellent corrosion resistance and weatherability, suitable for various indoor and outdoor environments.

- Aluminum material offers good ductility, and coating adhesion is strong, meeting the requirements of complex forming processes such as deep drawing and spinning.

- Finely treated surface, smooth and flat, with no noticeable color difference, scratches, or coating cracks.

- Lightweight material with good recyclability, complying with environmental and sustainability requirements.

Applications of Color Coated Aluminum Circle Disc

Color-coated aluminum circle discs, after surface coloring treatment, do not require additional spraying or painting after forming, significantly saving production steps and reducing environmental impact. With excellent processing performance and outstanding decorative effect, these aluminum discs demonstrate wide application potential across multiple industries:

Cookware and Kitchenware

Suitable for making frying pans, saucepans, pressure cookers, rice cooker inner pots, and lids.

- Features: Even heat distribution, easy to clean, rich and attractive colors

- Advantages: Exterior can feature vibrant and colorful designs; interior can be non-stick, providing practical and aesthetically pleasing solutions for kitchenware

Architecture and Interior Decoration

Can be used for exterior wall panels, interior ceilings, curtain wall components, circular ceiling panels, wall decorative elements, and various art installations.

- Features: Diverse colors, modern aesthetic

- Advantages: Enhances architectural beauty while ensuring durability and ease of maintenance, making it an ideal choice for decorative aluminum sheets

Lighting Applications

Suitable for lampshades, reflectors, and optical or decorative components.

- Features: Ensures optical performance and enhances lighting quality

- Advantages: Combines functionality and aesthetics, delivering softer light and more refined designs

Home Appliances and Consumer Products

Widely used in washing machine panels, refrigerator decorative parts, air conditioner shells, and more.

- Features: Durable, easy to clean, long-lasting colors

- Advantages: Improves overall visual appeal, enhancing quality and premium feel of products

Other Applications

Suitable for signage, nameplates, bottle caps, medical device components, automotive interior parts, and various promotional items.

- Advantages: Wide range of applications, combining practicality with decorative effect

- Features: Meets the needs of various scenarios for color aluminum circle discs, flexibly applied across multiple industries

Advantages of Color Coated Aluminum Circle Disc

- Corrosion Resistance: Coating acts as a barrier against moisture, acids, and oxidation.

- Deep Drawing Performance: High-quality circular aluminum sheets can be stretched into deep pot shapes without coating cracking or peeling.

- Environmentally Friendly: Pre-coated aluminum is 100% recyclable, and modern industrial coating lines are designed to capture and recover solvents.

- Aesthetic Diversity: Available in any RAL or Pantone color, as well as wood grain or stone patterns.

- Color Stability: Coating contains active molecules that form a protective layer, resisting fading and UV exposure, keeping colors vibrant for long periods.

- Excellent Workability: Easy to stamp, bend, weld, and form into complex shapes (e.g., curves, waves).

- Lightweight: Density only 2.7g/cm³, about three times lighter than steel, convenient for transportation and installation.

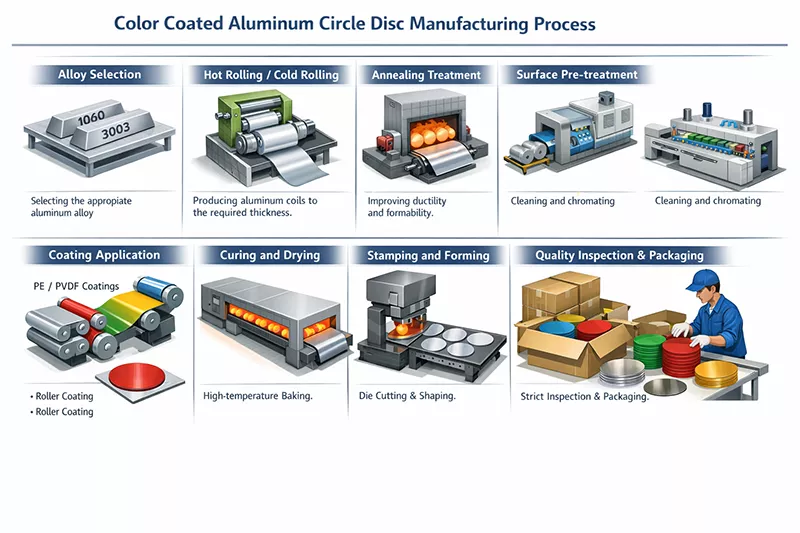

Manufacturing Process of Color Coated Aluminum Circle Disc

First, the appropriate aluminum material is selected according to the intended application: 1060 is commonly used for cookware, while 3003 is more often used for architectural decoration. After selecting the material, the aluminum coil undergoes hot rolling or cold rolling to achieve the desired thickness. To improve formability, the aluminum is annealed, enhancing its ductility and flexibility.

Next comes surface treatment. The aluminum coil is first thoroughly cleaned and then chromated to ensure that subsequent coatings adhere firmly and are more durable. The coating process can be carried out by roll coating or spraying, with PE, PVDF, and other coatings applied in multiple layers to increase service life. After coating, the material is baked at high temperatures to fully cure the coating, ensuring it does not easily peel or flake.

Finally, the aluminum coil enters the stamping stage, where it is cut into circular shapes using molds, and the edges are chamfered or polished. Each finished disc undergoes strict quality inspection to verify dimensions and coating integrity, and is then carefully packaged to ensure it reaches the customer in perfect condition.

Haomei Aluminum Color Coated Aluminum Circle Disc Selection Guide

At Haomei Aluminum, we offer a variety of color aluminum circle solutions for different application scenarios, helping customers easily choose the right product:

Application Scenario – Choose the Right Coating

- Outdoor Use: PVDF coating provides excellent weather resistance, maintaining color and performance stability for over 10 years.

- Indoor Use: PE coating is cost-effective and suitable for decorative or light-duty applications.

Material Selection – Balance Strength and Performance

- Everyday decorative or light-duty parts: 1060 aluminum offers flexible processing and stable performance.

- Load-bearing or structural components: 3003/5052 alloys provide higher strength and reliability, ensuring long-term safety.

Thickness Selection – Match the Processing Technique

- Stamped parts: Recommended thickness 0.3–0.6mm, suitable for deep drawing and precise forming.

- Structural support components: Recommended thickness 0.8–1.0mm, balancing stability and durability.

Customized Services – Meet Diverse Needs

- Color: Precise customization according to RAL or PANTONE standards.

- Surface Finish: Various options including glossy, matte, and textured.

- Dimensions: Can be precisely processed according to customer requirements, ensuring perfect fit of parts.

Haomei Aluminum is always focused on providing high-quality aluminum solutions, committed to delivering reliable, durable, and aesthetically pleasing color aluminum circle discs, meeting the diverse needs of industrial, decorative, and professional manufacturing applications.