1″ / 2″ / 3″ / 4″ Wide Aluminum Strips for Sale

As a professional manufacturer with long-term expertise in high-quality aluminum products, we offer a wide range of aluminum strip specifications, including 1-inch, 2-inch, 3-inch, and 4-inch widths, to meet the practical needs of different industries and application scenarios. This series of aluminum strips is made from carefully selected aluminum alloy raw materials and processed through precision manufacturing techniques, ensuring stable and reliable performance in terms of strength, corrosion resistance, and workability. Whether for industrial manufacturing, construction projects, automotive components, or various commercial and DIY applications, these aluminum strips deliver excellent usability and finished results.

Aluminum Strip Specifications for Sale

Depending on the scale of the project, the width of the strip can significantly affect structural support or the overall aesthetic appearance.

| Width | Best for Applications |

| 1″ Aluminum Strip | Precision brackets, electrical busbars, trim work, and model making. |

| 2″ Aluminum Strip | Edge banding, decorative accents, structural bracing, and automotive trim. |

| 3″ Aluminum Strip | Custom signage frames, solar panel mounting, and heavy-duty architectural accents. |

| 4″ Aluminum Strip | Roofing flashings, industrial machinery guards, and baseplates for mounting hardware. |

By purchasing directly from us, you can eliminate all intermediary steps and enjoy more competitive factory-direct pricing while ensuring consistent and stable quality. Every batch of products undergoes strict quality control to guarantee reliable delivery and peace of mind in use.

We can provide you with:

- Custom length service: If you have special size requirements, high-precision cutting can be carried out according to your drawings or specifications.

- Flexible volume-based pricing options: For bulk purchases or long-term cooperation projects, we offer more competitive tiered discounts.

- Efficient shipping assurance: Professional packaging solutions are used to effectively prevent deformation or surface damage during transportation.

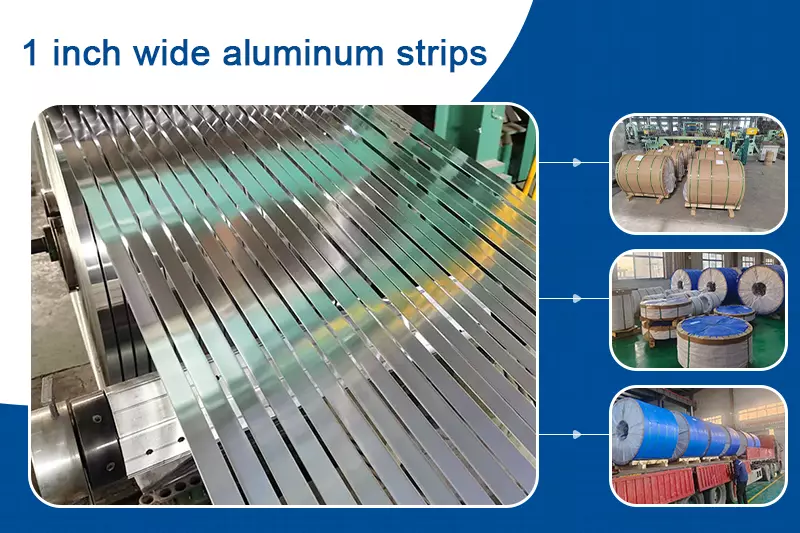

1 Inch Wide Aluminum Strips

1 inch wide aluminum strips are designed for applications that demand accuracy and flexibility. Thanks to their slim profile, they are easy to cut, bend, and shape, making them a practical choice for electrical components, decorative edging, heat dissipation parts, and other light fabrication work. Despite their narrow width, they still deliver the corrosion resistance and lightweight performance aluminum is known for.

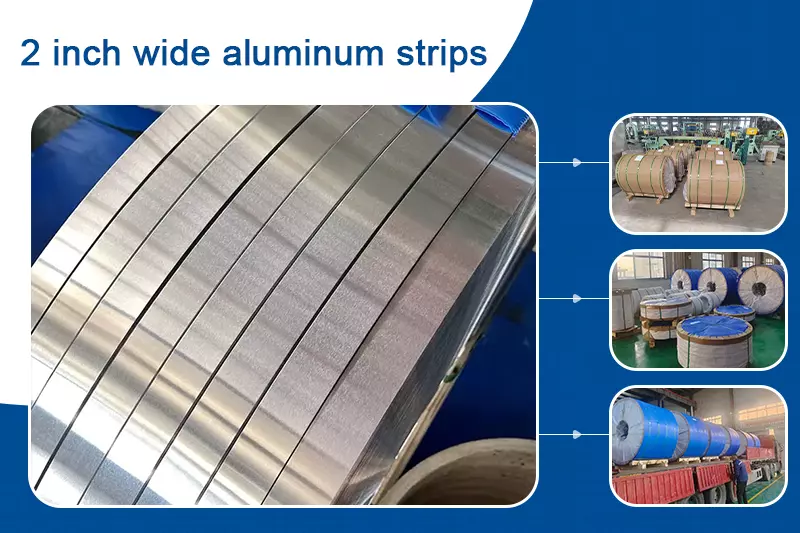

2 Inch Wide Aluminum Strips

2 inch wide aluminum strips strike a good balance between strength and ease of processing. They are frequently used in construction fittings, automotive components, signage systems, and general industrial manufacturing. The added width provides better stability compared to narrower strips, while remaining well suited for stamping, forming, and rolling processes.

3 Inch Wide Aluminum Strips

3 inch wide aluminum strips are commonly selected for industrial and semi-structural applications where extra rigidity is required. Typical uses include machine parts, brackets, insulation assemblies, and decorative panels. The increased surface area helps distribute loads more evenly, improving durability without compromising workability.

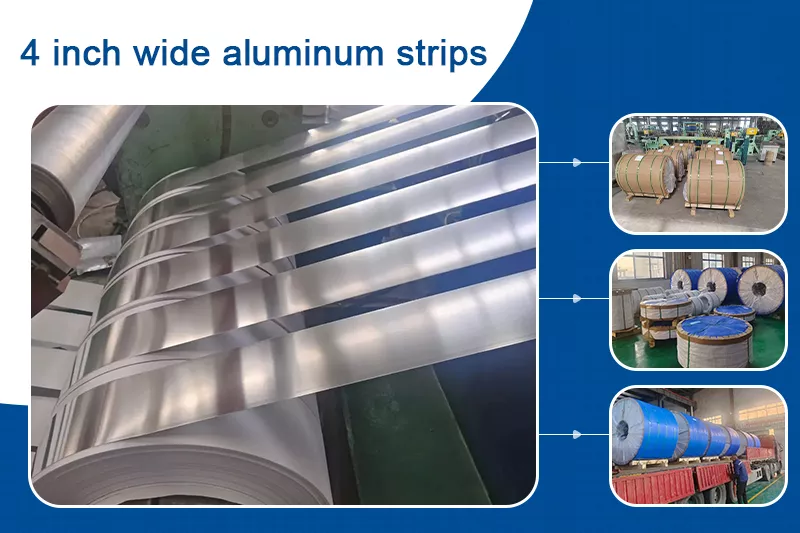

4 Inch Wide Aluminum Strips

4 inch wide aluminum strips are intended for applications that require wider coverage and higher mechanical performance. They are widely used in building materials, industrial equipment, cladding systems, and custom fabrication projects. With their broader width and consistent quality, these strips offer excellent strength, reliability, and long-term service life.

Haomei Alloy Aluminum Strips for Sale

| Series | Alloy Aluminum Strip | Strength | Typical Applications |

| 1xxx | 1050 / 1060 Aluminum Strip | Low | Electrical, Deep Drawing |

| 3xxx | 3003 / 3105 Aluminum Strip | Medium | Construction, Color Coating |

| 5xxx | 5052 / 5754 Aluminum Strip | Relatively High | Automotive, Marine |

| 6xxx | 6061 / 6063 Aluminum Strip | High | Industrial Structures |

| 8xxx | 8011 / 8079 Aluminum Strip | Medium | Packaging, Cables |

1xxx Series (High-Purity Aluminum Strips)

Common Alloys: 1050 / 1060 / 1070 / 1100

Features:

The 1xxx series aluminum strips are primarily high-purity aluminum with extremely high aluminum content (1070 ≥ 99.7%), offering excellent electrical and thermal conductivity. They are highly ductile, making them ideal for stamping, stretching, and other forming processes. Although their strength is relatively low, they have excellent corrosion resistance and meet the requirements for applications that demand high purity and durability.

Main Applications:

- Electrical Industry: Transformer aluminum strips, cable sheathing

- Heat Dissipation Systems: Radiators, lamp reflectors

- Deep Drawing: Aluminum foil blanks, various deep-drawn products

- Architectural Decoration: Curtain wall aluminum strips, decorative trims

3xxx Series (Aluminum-Manganese Alloy Strips)

Common Alloys: 3003 / 3004 / 3105

Features:

The 3xxx series mainly consists of aluminum-manganese alloys. Its strength is significantly higher than the 1xxx series, while maintaining excellent corrosion resistance. These strips are easy to form and weld, offering flexible processing and high cost-effectiveness, making them ideal for large-scale industrial production and construction applications.

Main Applications:

- Base material for color-coated aluminum strips

- Roofs, wall panels, and curtain wall systems

- Window shutters, aluminum tiles, and other decorative strips

- Packaging aluminum strips

5xxx Series (Aluminum-Magnesium Alloy Strips)

Common Alloys: 5052 / 5083 / 5754

Features:

The 5xxx series aluminum strips are mainly aluminum-magnesium alloys, with higher strength than the 3xxx series and excellent corrosion resistance, especially suitable for marine and humid environments. They have good fatigue resistance and are weldable, but not suitable for heat treatment strengthening, making them ideal for long-term use and stress-bearing applications.

Main Applications:

- Shipbuilding and marine engineering structural components

- Automotive interior and exterior parts

- Fuel tanks, pressure vessels

- Industrial step aluminum strips, anti-slip strips, and structural parts

6xxx Series (Aluminum-Magnesium-Silicon Alloy Strips)

Common Alloys: 6061 / 6063 / 6082

Features:

The 6xxx series aluminum strips can be strengthened through heat treatment, balancing strength and processability. They have stable corrosion resistance and can be anodized to achieve smooth and bright surfaces with an elegant appearance. Suitable for industrial structures and architectural decoration.

Main Applications:

- Aluminum strips for industrial structures

- Architectural decorative trims and profile cutting strips

- Rail transit components

- Various machinery parts

8xxx Series (Aluminum-Iron / Aluminum-Silicon Alloy Strips)

Common Alloys: 8011 / 8079

Features:

The 8xxx series aluminum strips have higher strength than the 1xxx series and offer good sealing and barrier properties. They are stable during processing, especially for thin gauges, and perform excellently in food, pharmaceutical, and industrial packaging applications.

Main Applications:

- Food and pharmaceutical packaging aluminum strips

- Aluminum-plastic composite cables

- Air conditioning and insulation materials

- Other industrial aluminum strips requiring sealing and barrier performance

How to Choose the Right Aluminum Strip?

Choosing aluminum material mainly depends on your specific needs:

- Focus on electrical conductivity and ease of processing? 1050, 1060, 1070 are ideal choices—soft, easy to form, and easy to process.

- Want daily decorative effects with high cost-effectiveness? 3003, 3004 are not only visually appealing but also budget-friendly.

- Need both strength and corrosion resistance? 5052, 5754 offer balanced performance and can be confidently used outdoors or in humid environments.

- Require high-strength structural parts? 6061, 6063 provide solid support and excellent load-bearing performance.

- For packaging applications? 8011, 8079 are thin, flexible, and easy to form and transport.

Selecting the right material is actually simple—once you clarify the application, you can quickly pinpoint the most suitable aluminum alloy type.

Applications of 1″ / 2″ / 3″ / 4″ Wide Aluminum Strips

- Industrial manufacturing and mechanical components

- Construction and decorative trims

- Automotive parts and accessories

- Electrical and electronic enclosures

- DIY and craft projects

Why Choose Us

As a manufacturer specializing in aluminum production, Haomei Aluminum maintains full control over every process from raw materials to finished products. This allows us to consistently ensure product quality, dimensional accuracy, and delivery efficiency, while also offering customers more competitive pricing. Our aluminum strips support long-term and large-volume supply, and can be flexibly customized in terms of length, thickness, and surface treatment according to project requirements.

We typically use premium aluminum alloys such as 6061 or 5052 for production, ensuring stable and reliable performance across different application environments. Compared with similar products, our aluminum strips offer the following significant advantages:

- Excellent corrosion resistance: A dense natural oxide protective layer forms on the aluminum surface, making it suitable for a wide range of indoor and outdoor applications.

- Outstanding strength-to-weight ratio: While remaining lightweight, the strips still provide good structural strength and can replace certain heavier metal materials.

- Good workability: Aluminum strips are easy to cut, bend, drill, and weld, enabling efficient integration with various processes and project requirements.

- Stable and attractive surface quality: Multiple surface finishes are available, including mill finish, brushed, and anodized, to meet both functional and aesthetic design needs.