8079 Aluminum Foil

8079 aluminum foil is an aluminum alloy foil primarily composed of aluminum, with specific proportions of iron (Fe), silicon (Si), and other elements added. It features excellent comprehensive properties and is widely used in high-end packaging fields.

8079 aluminum foil is a high-performance material commonly applied in industries requiring outstanding barrier properties, flexibility, and formability. It is especially prevalent in food, pharmaceutical, and industrial packaging applications.

- Alloy Type: 8079 aluminum foil belongs to the 8xxx series of aluminum alloys.

- Common Tempers: Includes H14, H18, and other temper states.

- Thickness Range: From 10 micrometers to 200 micrometers.

- Main Components: Aluminum metal with a purity of up to 99.79%, containing small amounts of zinc, chromium, and other elements to enhance corrosion resistance and oxidation resistance.

8079 Aluminum Foil Specifications and Dimensions

Thickness Specifications

- Thick Foil: 0.1~0.2mm

- Single Zero Foil: 0.01~0.1mm

- Double Zero Foil: 0.005~0.009mm

Width and Length Specifications

Width Range: Standard width ranges from 100 to 1600mm, wider sizes can be provided.

Length Range: Usually supplied in coil form, length can be customized according to customer requirements, generally marked as "C" to indicate customized length.

Core Characteristics of 8079 Aluminum Foil

- High Strength and Good Ductility: 8079 aluminum foil is a high-strength foil product with good elongation and rolling properties. In soft-pack battery applications, its strength can reach 90-110 MPa, elongation 13%-18%, and Erichsen value 6.2-7.3mm.

- Excellent Barrier Properties: 8079 aluminum foil offers superior moisture resistance, gas barrier performance, and flavor retention, effectively protecting packaged contents. These features make it ideal for high-barrier applications.

- Stable Temperature Adaptability: 8079 aluminum foil maintains its shape under extreme temperature conditions, withstanding -73 to 371°C without expansion or deformation, making it suitable for a wide range of temperature applications.

- Good Surface Properties: With advanced production processes, the surface of 8079 aluminum foil is clean, flat, and oil-free, offering strong bonding performance during lamination, and is resistant to delamination.

- Excellent Workability: 8079 aluminum foil has good formability and puncture resistance, making it easy to process into complex shapes.

8079 Aluminum Foil Temper States and Their Characteristics

Common Temper States

8079 O Temper (Annealed Condition)

Characteristics: Fully annealed to the softest state, good plasticity and high elongation

Processability: Excellent deep drawing performance, suitable for complex forming processes

Application Scenarios: Mainly used in applications requiring deep drawing, such as battery soft packs, cold-formed pharmaceutical foil, etc.

8079 H18 Temper (Full Hard Condition)

Characteristics: High strength and hardness, but lower ductility

Processability: More difficult to process, suitable for simple forming or non-forming applications

Application Scenarios: Commonly used in situations requiring high hardness and strength, such as pharmaceutical foil and bottle cap materials

8079 H22, H24 Temper (Half Hard Condition)

Characteristics: Moderate strength and hardness, with certain ductility

Processability: Suitable for medium-level forming processes

Application Scenarios: Widely used in food packaging, tape foil, and other fields

Effect of Temper on 8079 Aluminum Foil Properties

Different temper conditions significantly affect the mechanical and processing properties of 8079 aluminum foil:

Strength and Hardness: As the temper changes from O to H18, the strength and hardness of the aluminum foil gradually increase, while the elongation decreases.

Processability: O temper foil offers the best deep drawing and ductility performance, suitable for complex forming; H18 temper foil has high hardness, suitable for simple punching or non-forming uses.

Application Selection: Applications requiring deep drawing typically choose O temper foil; applications requiring higher strength and hardness usually choose H18 temper foil.

Surface Treatment Methods of 8079 Aluminum Foil

8079 Aluminum Foil Surface Treatments

- 8079 Plain Aluminum Foil (Plain Foil): 8079 plain aluminum foil has a smooth surface without additional processing. It is commonly used in food packaging, household foil, and industrial applications where basic barrier and forming properties are required.

- 8079 Composite Aluminum Foil: 8079 composite aluminum foil combines aluminum with paper, plastic, or film through lamination. It provides enhanced barrier, moisture-proof, oil-proof, or mechanical strength. Typical applications include coffee bags, seasoning packaging, and pharmaceutical packaging.

- 8079 Embossed Aluminum Foil: 8079 embossed aluminum foil features textured or patterned surfaces. It improves aesthetics, increases friction, and adds structural strength. Commonly used for baking cups, decorative food packaging, gift wrapping, and disposable tableware.

- 8079 Laminated Aluminum Foil: 8079 laminated aluminum foil is made by bonding aluminum foil with plastic films or paper to form multi-layer materials. It provides superior barrier performance, tear resistance, and sealability. Typical uses include high-barrier food packaging, pharmaceutical blister packs, and composite bags.

- 8079 Color Coated Aluminum Foil: 8079 color coated aluminum foil has a surface coated with colored layers, single or double sided. It is aesthetically pleasing, corrosion-resistant, and printable, enhancing packaging value. Commonly used in food gift packaging, beverage packaging, and decorative packaging.

- 8079 Coated Aluminum Foil: 8079 coated aluminum foil has functional coatings such as high-temperature resistant, anti-oxidation, or non-stick layers. It improves chemical resistance, corrosion resistance, or non-stick properties for specific industrial or food applications. Typical applications include baking paper, oven liners, special industrial packaging, and pharmaceutical packaging.

Surface Cleaning Treatment

Surface cleaning is a critical step in the production of 8079 aluminum foil, directly affecting its subsequent processing and application performance:

Degreasing

Process Characteristics: Uses advanced online degreasing technology during rolling to ensure a clean surface

Application Effect: Effectively ensures surface cleanliness without affecting mechanical strength

Importance: Essential for subsequent lamination, printing, or coating applications

De-oiling Treatment

Applying Conditions: Hard foil requires de-oiling before printing, lamination, or coating

Treatment Methods: Typically uses chemical degreasing or solvent cleaning methods

Treatment Effect: Ensures an oil-free surface to enhance adhesion in subsequent processes

Surface Coating Treatments

To meet specific application requirements, 8079 aluminum foil surfaces can undergo various coating treatments:

Anti-Corrosion Coating

Coating Material: Typically organic resin or polymer materials

Application Scenarios: Used in environments requiring improved corrosion resistance

Treatment Effect: Effectively enhances the corrosion resistance and service life of the aluminum foil

Heat Seal Coating

Coating Material: Thermoplastic adhesives such as polyurethane or vinyl

Application Scenarios: Packaging applications requiring heat sealing, such as food and pharmaceutical packaging

Treatment Effect: Provides excellent heat seal performance to ensure sealing effectiveness

Impact of Surface Treatments on Performance

Different surface treatments significantly influence the performance of 8079 aluminum foil:

Surface Tension: Proper surface treatment can improve surface tension, generally required to be no less than 32 dynes

Adhesion: Good surface treatment enhances adhesion of coatings and printing inks

Barrier Performance: Certain surface treatments can further improve the barrier properties of aluminum foil

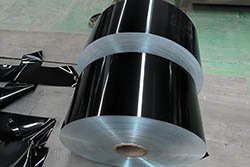

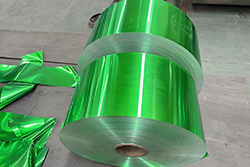

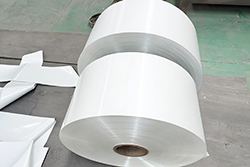

8079 Aluminum Foil Color Options

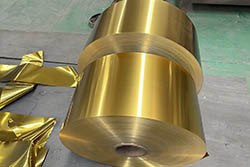

-

gold 8079 aluminum foil

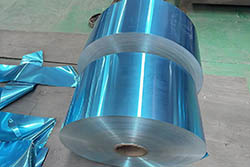

-

blue 8079 aluminum foil

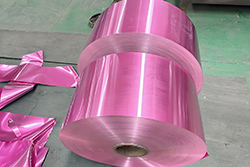

-

pink 8079 aluminum foil

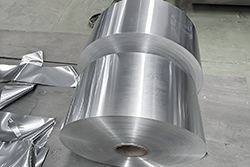

-

silver 8079 aluminum foil

-

black 8079 aluminum foil

-

bronze 8079 aluminum foil

-

green 8079 aluminum foil

-

white 8079 aluminum foil

Barrier Properties of 8079 Aluminum Foil

| Performance Indicator | Feature | Test Method | Typical Value |

| Moisture Resistance | Extremely high moisture resistance | Water Vapor Transmission Rate (WVTR) | Premium foil should be < 0.5g/(m²·24h) |

| Gas Barrier | Excellent gas barrier properties | Oxygen Transmission Rate (OTR) | Typically < 0.5cm³/(m²·24h·0.1MPa) |

| Light Blocking | Excellent light-blocking performance | Light Transmission Test | Almost completely blocks light |

Haomei Aluminum 8079 Foil Quality Inspection

Finished product quality inspection is the final step to ensure compliance with standards and customer requirements:

Dimensional Accuracy Inspection

Thickness Measurement: Uses laser or eddy current thickness gauges according to ASTM B479 and GB/T 3198 standards

Thickness Tolerance: Typically controlled within ±5%

Width and Length: Ensures compliance with contract tolerances, especially edge uniformity after slitting

Performance Testing

Mechanical Properties: Tensile strength, elongation, Erichsen value, etc., tested according to GB/T 228.1 standards

Surface Quality: Pinholes, oil stains, and surface wettability tension tests

Barrier Properties: Water vapor transmission rate, oxygen transmission rate, microbiological barrier tests

Advantages of 8079 aluminum foil

Barrier Properties

- Excellent Barrier: 8079 aluminum foil effectively isolates air, moisture, and odors, ensuring long-term protection of the packaged items.

- Moisture and Odor Resistance: Provides extremely high moisture resistance and gas blocking, effectively protecting the contents from external factors.

- Antibacterial Performance: Passes bacterial and mold tests, showing excellent non-toxic, odorless, safe, and hygienic properties.

Temperature Stability

High and Low-Temperature Adaptability: 8079 aluminum foil maintains shape stability without shrinking or deforming in a temperature range of -73°C to 371°C.

Conductivity and Light Blocking

- Good Conductivity: 8079 aluminum foil has good electrical conductivity, suitable for applications requiring electrical shielding.

- Excellent Light Blocking: Effectively blocks light, protecting light-sensitive products.

Flexibility and Processability

High Flexibility: 8079 aluminum foil is highly flexible, easy to process and mold into various shapes, adapting to diverse packaging needs.

Safety

Non-toxic and Odorless: Ensures the safety of food and pharmaceuticals, meeting hygiene standards.

The price is slightly higher compared to other aluminum foil alloys, but its performance advantages make it very popular in high-end applications.

8079 Aluminum Foil Standards

- ASTM B479

- QQA-1876

8079 Aluminum Foil Surface Quality

- No black spots, lines, creases, wrinkles, etc.

- Surface quality: no air holes, no bulges, etc.

8079 Aluminum Foil Tolerance

Width tolerance: ±1.0mm

Thickness tolerance:

| Measurement Type | Tolerance |

| Spot measurement tolerance | ±6% |

| Average thickness tolerance (lot weight ≥3T) | ±5% |

| Average thickness tolerance (lot weight ≥10T) | ±4% |

8079 O Aluminum Foil Pinholes

| Alloy Temper | Thickness (mm) | Pinholes (per square meter) |

| 8079 O aluminum foil | 0.006 | Max 500 |

| 8079 O aluminum foil | 0.0063 | Max 400 |

| 8079 O aluminum foil | 0.0065 | Max 200 |

| 8079 O aluminum foil | 0.008 | Max 100 |

| 8079 O aluminum foil | 0.009 | Max 100 |

Aluminum Alloy 8079 Foil Chemical Properties

| Al | Reminder |

| Si | 0.50 - 0.30 |

| Fe | 0.70 – 1.3 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.10 |

| Other | ≤ 0.15 |

Mechanical Properties of 8079 Aluminum Alloy Foil

| Alloy Temper | Thickness (mm) | Tensile Strength (Mpa) | Elongation (%) |

| 8079 O aluminum foil | 0.006 | 50-100 | ≥1.0 |

| 8079 O aluminum foil | 0.0063 | 50-100 | ≥1.0 |

| 8079 O aluminum foil | 0.0065 | 50-100 | ≥1.0 |

| 8079 O aluminum foil | 0.008 | 50-100 | ≥1.0 |

| 8079 O aluminum foil | 0.009 | 60-100 | ≥1.5 |

| 8079 H18 aluminum foil | 0.035-0.2 | ≥160 | – |

| 8079 H19 aluminum foil | 0.035-0.2 | ≥170 | – |

| 8079 H22 aluminum foil | 0.035-0.04 | 90-150 | – |

| 8079 H22 aluminum foil | >0.04-0.09 | 90-150 | – |

| 8079 H22 aluminum foil | >0.09-0.14 | 90-150 | 5 |

| 8079 H22 aluminum foil | >0.14-0.2 | 90-150 | 6 |

| 8079 H24 aluminum foil | 0.035-0.04 | 120-170 | 2 |

| 8079 H24 aluminum foil | >0.04-0.09 | 120-170 | 3 |

| 8079 H24 aluminum foil | >0.09-0.14 | 120-170 | 4 |

| 8079 H24 aluminum foil | >0.14-0.2 | 120-170 | 5 |

Common Applications of 8079 Aluminum Foil with Corresponding Specifications and Tempers

8079 Aluminum Foil for Food Packaging

8079 aluminum foil is widely used in food packaging due to its excellent barrier properties and food-safe characteristics:

Typical Applications:

Food Packaging Foil: Used for packaging various foods such as meat, baked goods, candies, etc.

Foil Container Material: Used for making disposable food containers

Household Foil: Aluminum foil for home kitchen use

Common Specifications and Tempers:

Thickness: 0.01-0.2mm

Width: 300-1100mm

Temper: O, H24, H22, H18, etc.

Performance Requirements:

Food-grade safety standards, passing tests for bacteria, mold, etc.; non-toxic and odorless

Excellent moisture, gas barrier, and flavor retention properties

Good heat sealability and printability

8079 Aluminum Foil for Pharmaceutical Packaging

In pharmaceutical packaging, 8079 aluminum foil is an essential material due to its high barrier and safety performance:

Typical Applications:

Pharmaceutical Foil: Used for blister and tropical-type pharmaceutical packaging

Cold-Forming Foil: Used for high-end pharmaceutical blister packs and high-seal pharmaceutical packaging

Common Specifications and Tempers:

Thickness: 0.016-0.08mm

Width: 100-1600mm

Temper: O, H18, etc.

Performance Requirements:

Extremely high barrier properties to ensure drug stability

Good cold forming performance

Strict surface quality requirements: no pinholes, voids, or corrosion marks

Compliant with hygiene standards for pharmaceutical packaging materials

8079 Aluminum Foil for Battery Soft Packaging

8079 aluminum foil is increasingly used in soft-pack lithium battery fields, especially for high-end battery products:

Typical Applications:

Soft-pack lithium battery aluminum plastic film foil: Used as the middle layer material of aluminum plastic film

Polymer lithium battery packaging aluminum composite film

Common Specifications and Tempers:

Thickness: 0.025-0.055mm; 0.04-0.08mm

Width: 100-1650mm

Temper: O

Performance Requirements:

Excellent thermal and electrical conductivity

High barrier performance to prevent water vapor ingress and electrolyte leakage

Good cold-forming and puncture resistance

Surface tension not less than 32 dynes

Other Industrial Applications

In addition to the above key areas, 8079 aluminum foil also finds wide use in various industrial fields:

Typical Applications:

Tape Foil: Used as a base material for various tapes

Cable Foil: Used for shielding and protection of cables

Decorative Foil: Used for decorative materials and crafts

Common Specifications and Tempers:

Thickness: 0.016-0.4mm

Temper: H18, O, etc.

Performance Requirements:

Good conductivity and opacity

Excellent mechanical workability

Compliance with specific industrial application standards

Comparison Analysis of 8079 Aluminum Foil with Other 8-Series Foils

Classification and Characteristics of 8-Series Aluminum Foil

8-series aluminum alloys are important materials for aluminum foil, mainly including the following common alloys:

8-Series Alloy Classification:

Main Alloys: 8011, 8021, 8079, etc.

Alloy Characteristics: Mainly added with iron and silicon as major alloying elements, featuring moderate strength and good processing performance

Common Advantages: Excellent sealing, plasticity, corrosion resistance, etc.

Application Fields of 8-Series Aluminum Foil:

Widely used in food and beverage, cigarette and pharmaceutical packaging, household daily use, etc.

Especially suitable for packaging applications requiring high barrier properties

Also important in electronics and battery sectors

Comparison Between 8079 and 8011 Aluminum Foil

8011 is the most widely used aluminum foil in the 8-series alloys. Compared with 8079, it has the following characteristics:

Chemical Composition Differences:

Silicon Content: 8011 aluminum foil contains more silicon than 8079

Alloy Elements: 8011 contains manganese and magnesium, which are not present in 8079

Iron Content: 8079 aluminum foil has higher iron content than 8011

Performance Comparison:

Strength: 8011 has higher strength than 8079

Elongation: Under the same temper, 8079 has higher elongation than 8011

Puncture Resistance: 8079 has better puncture resistance than 8011

Processing Performance:

Formability: 8079 offers better deep drawing properties

Surface Treatment: 8011 is easier to treat and coat

Processing Cost: 8011 has relatively lower production cost

Application Fields:

8011 is more widely used in pharmaceutical packaging, food packaging, food containers, tape foil, cable foil, yogurt lid, bottle cap materials, and more

8079 is more suitable for high-end packaging applications that require better elongation and puncture resistance, such as food and pharmaceutical products

Comparison Between 8079 and 8021 Aluminum Foil

8021 aluminum foil is another key 8-series material. Compared with 8079, it has the following characteristics:

Chemical Composition Differences:

Silicon Content: 8021 contains less silicon than 8079

Iron Content: 8021 contains less iron than 8079

Alloy Elements: 8021 does not contain manganese or magnesium, same as 8079

Performance Comparison:

Strength: 8079 has slightly higher strength than 8021

Elongation: 8021 has slightly higher elongation than 8079

Deep Drawing Performance: 8021 offers better deep drawing properties

Processing Performance:

Rolling Process: 8021 is primarily hot-rolled; 8079 can be either hot-rolled or cast-rolled

Formability: 8021 performs better in deep drawing applications

Surface Quality: Both materials can achieve high surface quality

Application Fields:

8021 is mainly used in blister pharmaceutical foil and aluminum-plastic film for new energy battery packaging

8079 is more commonly used in packaging fields requiring higher strength

Both are applied in high-end pharmaceutical packaging, but 8021 is more commonly used in blister and tropical aluminum

Overall Comparison and Selection Recommendations for 8-Series Aluminum Foil

Based on comprehensive comparison of main 8-series aluminum foil materials, the following recommendations can be made:

Overall Performance Comparison:

Strength Ranking: 8011 > 8079 > 8021

Elongation Ranking: 8021 > 8079 > 8011

Deep Drawing Performance: 8021 > 8079 > 8011

Puncture Resistance: 8079 > 8021 > 8011

Cost and Cost-Effectiveness:

Material Cost: 8011 < 8079 < 8021

Processing Cost: 8011 < 8079 < 8021

Cost-Effectiveness Evaluation: Should be assessed according to specific application needs

Application Scenario Recommendations:

General Packaging Applications: Prioritize 8011 for its high cost-effectiveness

Deep Drawing Applications: Prioritize 8021 for its superior formability

High-Strength Packaging Applications: Prioritize 8079 for its balanced strength and elongation

High-End Pharmaceutical Packaging: Choose 8021 or 8079 depending on specific requirements

Battery Soft Pack Applications: 8021 is more commonly used, but 8079 is also applicable under certain requirements

Key Points in Selecting 8079 Aluminum Foil

Selection Guide for 8079 Foil Specifications and Dimensions

Choose appropriate 8079 aluminum foil specifications based on application requirements:

| Selection Factors | Considerations | Common Choices |

| Thickness Selection | Barrier performance requirements, processing performance needs, cost considerations | Food packaging: 0.01–0.02mm; Pharmaceutical packaging: 0.016–0.04mm; Battery pouch: 0.025–0.055mm |

| Width Selection | Equipment limitations, usage efficiency, transportation and storage | Choose appropriate width based on production equipment and material utilization |

| Length Selection | Production batch size, storage conditions, ease of use | Select roll length according to production scale and ease of handling |

8079 Aluminum Foil Temper Selection Guide

Select the appropriate temper state according to application requirements and processing technology:

Formability Requirements and Temper Selection

Deep drawing applications: Generally choose O temper (annealed), offering the best ductility and formability

Simple stamping applications: H22 or H24 tempers are suitable, balancing strength and formability

Non-forming applications: H18 temper is suitable, providing high strength and hardness

Strength Requirements and Temper Selection

High strength requirements: Choose H18 temper for maximum strength and hardness

Moderate strength requirements: Choose H22 or H24 temper

Low strength requirements: Choose O temper, which offers the lowest strength but best ductility

Common Issues and Solutions in the Use of 8079 Aluminum Foil

Surface Quality Issues and Treatment

Potential surface quality issues and solutions during the use of 8079 aluminum foil:

| Issue | Symptom | Cause | Solution |

| Pinhole Problem | Micro holes on the aluminum foil surface | Impurities in raw materials, foreign matter intrusion during rolling | Choose reliable suppliers, perform pinhole inspection before use |

| Oil Stain Issue | Excessive rolling oil residue on foil surface | Poor oil control during rolling, inadequate degreasing process | Use well-treated foil, perform cleaning before use |

| Roll Marks and Uneven Gloss | Cyclic roll marks or uneven gloss on foil surface | Damaged roller surface, improper grinding, insufficient cleaning | Use foil with good surface quality, adjust lamination process parameters |

Processing Performance Issues and Treatment

Potential processing problems and solutions during the manufacturing of 8079 aluminum foil:

| Issue | Symptom | Cause | Solution |

| Forming Cracks | Cracks appearing during deep drawing or stamping | Insufficient ductility of material, improper temper selection | Select suitable temper, adjust processing parameters |

| Wrinkling | Foil shows creases during processing or use | Poor flatness, improper tension control, uneven rewinding | Use foil with good flatness, adjust tension control system of processing equipment |

| Insufficient Lamination Strength | Low peel strength after lamination with other materials | Poor surface treatment, improper lamination process parameters | Use foil with proper surface treatment, adjust lamination temperature, pressure, and time |

Application Performance Issues and Solutions

Potential performance issues and corresponding solutions in the actual application of 8079 aluminum foil:

| Issue | Symptom | Cause | Solution |

| Decline in Barrier Performance | Shortened shelf life of packaged products | Insufficient foil thickness, excessive pinholes, improper lamination process | Select products with appropriate thickness, optimize lamination process |

| Poor Heat Sealing | Unreliable sealing at heat-sealed areas, resulting in air leakage | Inappropriate heat sealing temperature, pressure, or time | Adjust heat sealing parameters, select products with good heat seal performance |

| Corrosion Issues | Corrosion spots appearing on foil during use | Exposure to corrosive substances, high environmental humidity | Choose products with anti-corrosion coatings, improve storage and usage environment |

Haomei Aluminum Foil Product Range

- 8011 Aluminum Foil 8011 possesses multiple excellent properties, including outstanding barrier ability against oxygen, moisture, and light. It is commonly used for pharmaceutical packaging, food packaging, aluminum foil tape, cable wraps, aluminum bottle caps, and more.

- 8021 Aluminum Foil 8021 is known for its exceptional barrier properties, safety, and good processing performance. It effectively blocks moisture and oxygen, is non-toxic and odorless, and is suitable for cold-formed pharmaceutical foil packaging, aluminum foil for lithium battery pouches, etc.

- 8006 Aluminum Foil With a bright surface, higher strength, and excellent anti-wrinkle performance, 8006 foil resists edge wrinkling during stamping and maintains a flat appearance. It is ideal for producing wrinkle-free food containers, airline meal boxes, and wrinkle-free pastry cups—scenarios requiring high standards in appearance and performance.

- 1235 Aluminum Foil With an aluminum content of no less than 99.35%, 1235 foil features excellent rust resistance, formability, and weldability. It is widely used in cable wraps, tape foil, and aluminum foil for lithium battery cathodes.

- 1060 Aluminum Foil 1060 aluminum foil belongs to the pure aluminum category (aluminum content ≥99.6%) and boasts excellent ductility and formability, along with good thermal conductivity and corrosion resistance. It is widely used in aluminum gaskets, electrolytic capacitors, and automotive heat shields.

- 1100 Aluminum Foil 1100 foil has slightly higher strength among pure aluminum foils and can be stamped, bent, and processed. It is commonly used in kitchenware (such as baking tray liners and foil sheets), insulation materials, and isolation layers of electronic components.

- 1070 Aluminum Foil Due to its high purity, 1070 aluminum foil offers superior electrical conductivity. It is suitable for applications such as capacitor electrode foil, precision electronic component packaging, high-end food packaging, and materials used in scientific research.

- 1050 Aluminum Foil With an aluminum content ≥99.5%, 1050 aluminum foil has balanced overall properties and is commonly used in capacitors, cable wraps, aluminum foil gaskets, and heat sinks. It is a widely used general-purpose pure aluminum foil material.

- 3003 Aluminum Foil Compared to pure aluminum foil, 3003 foil offers higher strength while maintaining good ductility and corrosion resistance. It is widely used in food containers (such as meal boxes and easy-open can lids), building soundproofing materials, HVAC ducts, and packaging materials.

- 3004 Aluminum Foil 3004 aluminum foil has greater strength and hardness than 3003, with good formability, suitable for deep-drawing processing. It is mainly used for meal box materials, aluminum honeycomb cores, beverage can bodies, and beverage packaging—meeting the industrial and packaging needs for high strength and formability.

- 5052 Aluminum Foil 5052 aluminum foil is a medium-strength alloy foil commonly used in scenarios requiring relatively high strength and corrosion resistance, such as honeycomb materials, door panel materials, meal box materials, and corrosion-resistant containers in the chemical industry. It is a medium- to high-end aluminum foil alloy with well-balanced comprehensive performance.

Users viewing this material also viewed the following

- 8011 8079 1235 Aluminum foil for yogurt packaging

- Blister Aluminium Foil 8011 8021 8079

- Cold Forming Aluminum Foil 8021 8079

- Pharmaceutical Aluminum Foil 8011 8021 8079

Recommended Content