6082 T651 Aluminum Plate Sheet

6082-T651 aluminum alloy is a high-strength, easy-to-machine, and corrosion-resistant aluminum alloy, particularly suitable for applications requiring high mechanical performance and structural stability.

6082-T651 aluminum alloy is a variant of 6082 aluminum alloy in the T651 temper. To achieve the T651 temper, this aluminum alloy undergoes several key heat treatment and processing steps to enhance its mechanical properties and stability.

6082-T651, based on the T6 temper (solution heat-treated + artificially aged), includes an additional stretching process (stretch deformation of 1%-3%), effectively eliminating internal stresses in the material and significantly improving machining stability and dimensional accuracy.

6082 T651 is an aluminum alloy with a specific heat treatment state, featuring high strength, excellent corrosion resistance, and good machinability, making it suitable for structural and aerospace applications. "6082" refers to the alloy series, mainly composed of aluminum, magnesium, and silicon, while "T651" denotes a specific heat treatment process, including solution heat treatment, artificial aging, and stress relief.

After heat treatment and mechanical processing, 6082 T651 exhibits extremely high stability, making it ideal for precision machining and manufacturing components subjected to high stress. Although the strength of 6082 is generally slightly higher than that of 6061.

6082 T651 Material Information

| Feature | Description |

| Alloy Series | 6000 (Aluminum-Magnesium-Silicon) |

| Primary Strengthening | Heat Treatable (Precipitation Hardening) |

| Key Properties | High Strength, Good Machinability, Excellent Corrosion Resistance, Good Weldability |

| Temper Process | Solution Heat-Treated, Quenched, Stretched (Stress-Relieved), and Artificially Aged. |

| Main Advantage | Excellent dimensional stability for machining complex parts with minimal warping. |

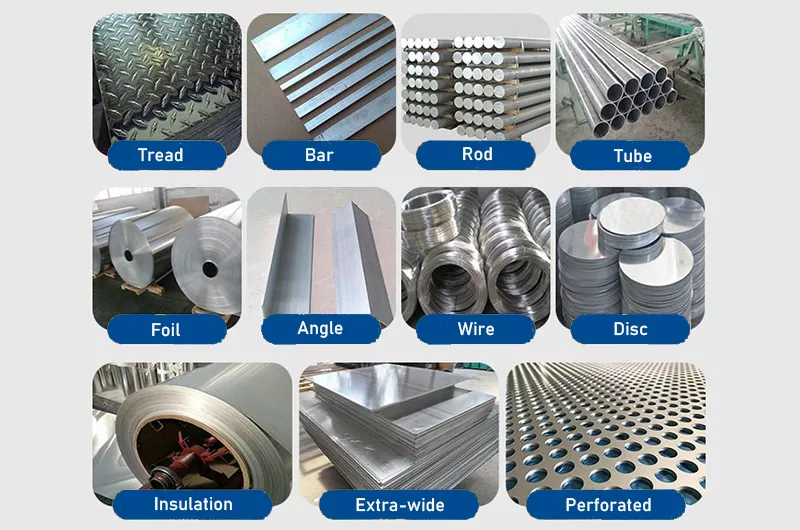

| Typical Forms | Plate, Sheet, Bar, and Extruded Shapes. |

The specifications for 6082 T651 Aluminum Sheet

| Alloy | 6082 |

| Temper | T651, T6511 etc. |

| Thickness | 0.5mm-300mm |

| Width | 500-2650mm |

| Length | 500-12000mm |

6082 T651 Alloy and Heat Treatment Condition

6082: A medium-strength, high-performance alloy in the 6000 series.

- Main Composition: Mainly aluminum, with key alloying elements including manganese, magnesium, and silicon.

- Performance: Its strength is generally superior to 6061 aluminum alloy and is often used as a reliable substitute for 6061.

T651: Heat treatment temper designation.

- Process: Indicates the material has undergone solution heat treatment, artificial aging, and stress relief.

- Characteristics: This process provides high strength while stress relief minimizes internal stresses, which is critical for aerospace applications.

- T6: Solution heat-treated and artificially aged to achieve peak strength.

- 51: Stress relieved by stretching, significantly enhancing dimensional stability, suitable for high-precision machining (such as molds and fixtures).

This temper allows the material to maintain high strength while reducing the risk of deformation during machining, especially suitable for complex structural components.

6082 T651 Aluminum Composition and Properties

6082-T651 aluminum alloy belongs to the 6 series of aluminum alloys, with silicon (Si) and magnesium (Mg) as the primary alloying elements. This alloy is widely used in the aluminum alloy family due to its excellent overall performance, offering superior strength, corrosion resistance, and good welding characteristics. Especially in the T651 condition, it exhibits higher stability and stress resistance compared to other conditions (such as T6).

| Element | Composition(%) |

| Si | 0.7-1.3 |

| Fe | 0.50 |

| Cu | 0.10 |

| Mn | 0.40-1.00 |

| Mg | 0.06-1.20 |

| Cr | 0.25 |

| Zn | 0.20 |

| Ti | 0.10 |

| Al | Remainder |

6082 T651 Aluminum Processing

- Solution Heat Treatment: First, the 6082 aluminum alloy is heated to a specific temperature, usually around 530°C, to fully dissolve the alloying elements into the aluminum matrix, forming a homogeneous solid solution.

- Stress Relief: To remove internal stresses generated during casting or processing, the 6082-T651 aluminum alloy undergoes a stress relief treatment. This process is achieved by stretching the metal by a certain amount, depending on the type of forged product being made (such as thin sheets, plates, rods, or forgings). Stress relief helps reduce warping and deformation that may occur during processing.

- Artificial Aging: After stress relief, the metal is heated to an appropriate temperature, usually between 160°C and 180°C, and held for a period of time to achieve the artificial aging condition. This process increases the strength and hardness of the aluminum alloy.

6082 T651 Aluminum Characteristics

- Higher Strength: 6082 aluminum alloy in T651 temper has higher strength than other alloy tempers, especially with significant improvement in yield and tensile strength.

- Excellent Ductility and Machinability: Although 6082-T651 aluminum alloy has high strength, it still maintains good ductility, making it easier to form complex shapes during machining and suitable for various processing methods.

- Good Corrosion Resistance: Due to added magnesium, 6082-T651 aluminum alloy exhibits excellent corrosion resistance, especially in marine and humid environments.

- Stability: The T651-treated alloy has high dimensional stability, especially after heat treatment, eliminating internal stresses from machining, ensuring better structural stability in subsequent use.

- Machinability: Exhibits excellent machinability, but the use of chip breakers is recommended for optimal results.

- Weldability: Good weldability, though strength in the heat-affected zone may be slightly reduced.

- Other Properties: Can be anodized, performing well in structural applications.

6082 T651 Aluminum Applications

6082-T651 aluminum alloy is primarily used in fields that require high strength and good machinability.

- Aerospace and Automotive Industries: As a structural material, it is used to manufacture components that bear heavy loads, such as fuselage frames, wing beams, and supporting structures. Its high strength and stability make it an ideal choice.

- Construction Engineering: In construction, 6082-T651 aluminum alloy is commonly used to make window frames, door frames, curtain walls, and structural support components due to its strong corrosion resistance, lightweight, and ability to withstand medium loads.

- Machinery Manufacturing: Suitable for various mechanical parts, especially those requiring further processing and forming, such as machine tools, brackets, frames, and tools.

- Transportation Equipment: Due to its high strength and excellent machinability, 6082-T651 aluminum alloy is widely used in the transportation industry, including key structural components in rail transportation, ships, automobiles, and aerospace.

- Bridges and Road Facilities: Due to its lightweight and high strength, 6082-T651 aluminum alloy can also be used in the construction of bridges, road equipment, and other infrastructure.

Typical Applications of 6082 T651 Aluminum Alloy

Transportation

- Automotive and New Energy: 6082 T651 aluminum alloy is widely used in truck frames, battery trays, and body frames. Lightweight design improves range and load efficiency while maintaining structural strength.

- Rail Transit: High-speed train seat frames, luggage racks, and other components fully demonstrate the high strength and weather resistance of 6082 T651, ensuring long-term safety and reliability.

- Shipbuilding: Used in decks, masts, and other non-pressurized structures, leveraging 6082 T651’s excellent resistance to seawater corrosion to extend service life.

Industrial and Machinery

- Mold Manufacturing: Injection molds and blow molds use 6082 T651 aluminum alloy, balancing thermal conductivity and machinability, aiding in complex cavity processing and cooling efficiency.

- Equipment Structures: CNC workbenches, robotic arms, and other high-precision equipment utilize the high rigidity and dimensional stability of 6082 T651 to ensure machining accuracy.

- Pressure Vessels: Tanks, end caps, and other components use 6082 T651, with weldability and high strength meeting strict safety standards.

Aerospace

- Non-load-bearing Components: Such as cargo floor panels and seat frames, using 6082 T651 aluminum alloy to balance strength and lightweight properties, aiding in energy saving and weight reduction.

- Auxiliary Supports and Equipment: Compliant with aerospace material certifications (e.g., AMS standards), 6082 T651 ensures reliability and safety.

Construction and Sports

- Architectural Structures: Pedestrian bridges, curtain wall frames, and scaffold load-bearing parts combine the high load capacity and weather resistance of 6082 T651, suitable for various outdoor environments.

- Sports Equipment: Bicycle frames, climbing gear, etc., utilizing 6082 T651 aluminum alloy to perfectly combine lightweight and high-strength advantages, enhancing performance and safety.

6082 T651 Aluminum Advantages

Improved Mechanical Properties: After undergoing solution heat treatment, stress relief, and artificial aging, 6082-T651 aluminum alloy provides significant strength improvements, making it suitable for high-demand structural applications.

Excellent Machinability and Weldability: Despite its high strength, 6082-T651 aluminum alloy retains good machinability and weldability, allowing it to be shaped through conventional machining methods and suitable for various welding processes.

Good Corrosion Resistance: Suitable for use in harsh environments, particularly in marine, chemical, or other extreme conditions.

6082 T651 Aluminum Mechanical Properties

| Property | Value |

| Brinell Hardness | 91 |

| Elastic Modulus (GPa) | 69 |

| Elongation at Break (%) | 6.3 |

| Fatigue Strength (MPa) | 94 |

| Poisson's Ratio | 0.33 |

| Shear Modulus (GPa) | 26 |

| Shear Strength (MPa) | 190 |

| Tensile Strength: Ultimate (UTS, MPa) | 320 |

| Tensile Strength: Yield (MPa) | 270 |

6082 T651 Aluminum Thermal Properties

| Property | Value |

| Latent Heat of Fusion (J/g) | 410 |

| Maximum Temperature: Mechanical (°C) | 170 |

| Melting Completion (Liquidus, °C) | 650 |

| Melting Onset (Solidus, °C) | 580 |

| Specific Heat Capacity (J/kg-K) | 900 |

| Thermal Conductivity (W/m-K) | 160 |

| Thermal Expansion (µm/m-K) | 23 |

6082 T651 Density

Density: Approximately 2.70 g/cm³ (2700 kg/m³), similar to most aluminum alloys.

Features: Offers a good strength-to-weight ratio, suitable for structural components, transportation, and aerospace lightweight applications.

6082 T651 Aluminum Electrical Properties

| Property | Value |

| Electrical Conductivity: Equal Volume (% IACS) | 42 |

| Electrical Conductivity: Equal Weight (% IACS) | 140 |

6082 T651 vs 6082 T6

| Parameter/Property | 6082 T651 | 6082 T6 | Description |

| Treatment Condition | Solution heat-treated, mechanically stress-relieved, and artificially aged | Solution heat-treated and directly artificially aged | T651 adds mechanical stress relief to T6, reducing warping or deformation |

| Strength | Slightly higher, with better stress corrosion resistance | High strength, but susceptible to stress corrosion | T651 is suitable for components that require stable performance after welding or complex machining |

| Applications | Structural parts, plates, profiles, aerospace, and automotive applications | General structural components | T651 is more suitable for high-precision and long-term engineering components |

6082 T651 vs 6082 T6511

| Parameter/Property | 6082 T651 | 6082 T6511 | Description |

| Treatment Condition | Solution + Stretch Stress Relief + Artificial Aging | T651 + Natural Aging Control | T6511 is "stress-relieved by stretching but not fully artificially aged, " suitable for more flexible sheets |

| Mechanical Properties | High Strength | Slightly lower than T651, but with better toughness | T6511 is suitable for applications requiring higher weldability or cold bending |

| Usage | Precision structural components | Flexible parts, welded structures | T6511 is often used for parts sensitive to deformation during processing |

6082 T6511 vs 6082 T6

| Parameter/Property | 6082 T6511 | 6082 T6 | Description |

| Strength | Medium-High | High | T6 has the highest strength but is more prone to stress corrosion |

| Toughness and Machinability | Better, suitable for cold bending and welding | Lower | T6511 is more stable during welding or complex machining |

| Stress Corrosion Resistance | Better | Lower | 6082 T6511 is more suitable for use in humid or corrosive environments |

6082 T6510

Treatment Condition: Solution heat-treated + Stretch Stress Relief, but not artificially aged (stress-relieved, no artificial aging)

Features:

- Strength slightly lower than T651, but can undergo artificial aging after subsequent processing

- More suitable for parts requiring cold working, welding, or complex cavity machining

- Maintains good dimensional stability and stress corrosion resistance

Haomei 6082 T651 aluminum plate in stock

| Procuct | Wide(in) | Length(in) |

| ASTM B209 ASME SB209 1/4" 6082 T651 Aluminum Plate 12" x 36" | 12" | 36" |

| ASTM B209 ASME SB209 3/8" 6082 T651 Aluminum Plate 12" x 36" | 12" | 36" |

| ASTM B209 ASME SB209 1/2" 6082 T651 Aluminum Plate 12" x 48" | 12" | 48" |

| ASTM B209 ASME SB209 5/8" 6082 T651 Aluminum Plate 24" x 24" | 24" | 24" |

| ASTM B209 ASME SB209 1" 6082 T651 Aluminum Plate 12" x 12" | 12" | 12" |

| ASTM B209 ASME SB209 1" 6082 T651 Aluminum Plate 12" x 24" | 12" | 24" |

| ASTM B209 ASME SB209 1" 6082 T651 Aluminum Plate 12" x 36" | 12" | 36" |

| ASTM B209 ASME SB209 1" 6082 T651 Aluminum Plate 24" x 24" | 24" | 24" |

| ASTM B209 ASME SB209 1.5" 6082 T651 Aluminum Plate 12" x 48" | 12" | 48" |

| ASTM B209 ASME SB209 1.5" 6082 T651 Aluminum Plate 24" x 24" | 24" | 24" |

| ASTM B209 ASME SB209 1.5" 6082 T651 Aluminum Plate 24" x 36" | 24" | 36" |

| ASTM B209 ASME SB209 1.75" 6082 T651 Aluminum Plate 12" x 12" | 12" | 12" |

| ASTM B209 ASME SB209 1.75" 6082 T651 Aluminum Plate 12" x 36" | 12" | 36" |

| ASTM B209 ASME SB209 1.75" 6082 T651 Aluminum Plate 12" x 48" | 12" | 48" |

6082 T651 Comparative Advantages and Alternatives

Difference between 6082 T651 and 6061 T651

- Higher Strength: 6082 T651 tensile strength is approximately 15-20% higher than 6061 T651, suitable for heavy-load scenarios (e.g., crane arms).

- Slightly Lower Weldability: Requires stricter control of heat input to avoid hot cracking, but post-weld treatment can compensate.

Alternative Material Selection

- Higher Strength: 7075 T651 (tensile strength ≥500 MPa) for critical components such as aircraft landing gear.

- Better Formability: 5052 H32 (elongation ≥12%) suitable for complex bent structures (e.g., automotive fuel tanks).

With the triple advantages of "high strength + high stability + easy machinability, " 6082 T651 has become a benchmark material in lightweight structural applications. Its widespread use in transportation, industrial equipment, and aerospace demonstrates its reliability under complex working conditions. By selecting appropriate processing techniques and surface treatments, its performance potential can be further maximized to meet high-end manufacturing requirements.

Relevant Questions about 6082 T651 Aluminum Plate Sheet

What is the difference between Al 6082 T6 and T651?

6082-T6 aluminum and 6082-T651 aluminum are variants of the same material. They share the same alloy composition and many physical characteristics, but differ in mechanical properties due to different processing methods.

What is aluminum 6082 equivalent to?

- AA6082

- HE30

- DIN 3.2315

- EN AW-6082

- ISO: Al Si1MgMn

- A96082

What is the difference between 6061 and 6082 aluminum?

6061 aluminum is more commonly used for structural applications due to its higher strength and good corrosion resistance, while 6082 aluminum offers slightly better machinability and is preferred for high-stress applications like marine environments.

What is marine grade aluminum 6082?

Marine grade aluminum 6082 is specifically designed to withstand harsh marine environments, offering excellent corrosion resistance, good weldability, and high strength characteristics suitable for shipbuilding and offshore structures.

Products you may be interested in

- 6082 Aluminum Plate Sheet

- 6082 T4 Aluminum Plate Sheet

- 6082 T6 Aluminum Plate Sheet

- 6082 O Aluminum Plate

- 6082 T42 Aluminum

- 6082 T451 Aluminum

- 6082 T5 Aluminum

- 6082 T61 Aluminum

- 6082 T6151 Aluminum

- 6082 T62 Aluminum

Further reading

Users viewing this material also viewed the following

- Aluminium Tooling Plate 6082

- 6082 Automotive Aluminum Sheet Plate

- Marine Grade 6082 Aluminum Plate

- 6082 Aerospace Grade Aluminum Sheet Plate

Recommended Content