5754 Aluminum Plate Sheet

What is aluminum grade 5754?

5754 aluminum alloy mainly consists of magnesium (AlMg3) and features excellent resistance to seawater and industrial corrosion. The 5754 alloy comes in various temper states, which affect its hardness, and it can be processed through cutting, bending, and stretching.

5754 aluminum sheet is a high strength non-heat treatable alloy with excellent corrosion resistance, good weldability and machinability. It is particularly suitable for seawater applications. 5754 is a wrought alloy, it can be formed by rolling, extrusion and forging.

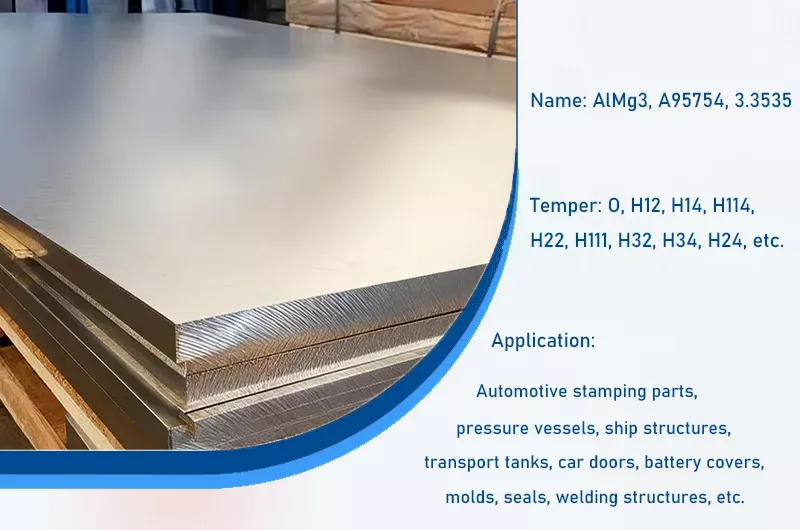

5754 aluminum plate is made from a 5000 series aluminum-magnesium alloy, also known as AlMg3, A95754, or 3.3535. This non-heat-treatable alloy is renowned for its outstanding resistance to atmospheric and seawater corrosion, making it a popular choice in marine, automotive, and industrial applications. It provides a good balance of strength and ductility, and its mechanical properties can be enhanced through cold working.

- Processing: has good machinability.

- Welding: has good weldability.

- Heat treatment: not heat treatable.

Haomei 5754 Aluminum Sheet and Plate Products and Specifications

| Alloy | 5754 aluminum plate sheet |

| Temper | O, H12, H14, H114, H22, H111, H32, H34, H24, etc. |

| Thickness(mm) | 0.20-600 customizable |

| Width(mm) | 100-2650 customizable |

| Length(mm) | 500-16000 customizable |

| Surface treatment | Rolled, Checkered aluminum plate, Anodized |

| Standard | GB/T 33227-2016, JIS H4000, ASTM B209, EN 485 |

| Application | Automotive stamping parts, pressure vessels, ship structures, transport tanks, car doors, battery covers, molds, seals, welding structures, etc. |

5754 Aluminium Sheet

High-quality aluminum-magnesium alloy sheet, known for excellent corrosion resistance, medium strength, and good formability.

- Temper Options: H111, H22, H24, H32, H34

- Thickness Range: 0.2mm – 6.0mm

- Width Range: 80mm – 2200mm

- Length Range: 1200mm – 6000mm

- Surface Treatments: Mill finish, anodized, brushed, painted

- Applications: Automotive panels, shipbuilding, pressure vessels, roofing, and architectural structures.

5754 Aluminium Plate

Thick aluminum plate offering superior corrosion resistance and structural integrity for heavy-duty applications.

- Temper Options: O, H111, H22, H24, H32

- Thickness Range: 6mm – 600mm

- Width Range: 800mm – 2650mm

- Length Range: 2000mm – 12000mm

- Surface Treatments: Mill finish, anodized, painted

- Applications: Ship decks, storage tanks, bridges, and industrial machinery components.

5754 Aluminum Alloy Tempers and Heat Treatment

The "temper" refers to the mechanical hardness of the alloy and can significantly alter its properties. Common tempers include:

- O: The softest temper.

- H111, H114: Others that are commonly used for specific applications.

- H22, H24, H26, H28: Harder tempers.

5754 Aluminum Plate Typical Temper

5754 in different heat treatment states is the main material used in the automotive manufacturing industry (passenger car doors, molds, seals) and canning industry.

5754 H111 Aluminum

- H111 state indicates light cold working, slightly higher strength than O state, with good ductility and formability.

- Core Features: Medium strength, excellent corrosion resistance, easy to process.

- Applications: Ship hulls, automotive panels, architectural structures, light machinery parts.

5754 H22 Aluminum

- H22 is a half-hard temper, moderately cold worked to increase strength while maintaining some ductility.

- Core Features: Medium-high strength, good corrosion resistance, moderate weldability.

- Applications: Pressure vessels, automotive structural parts, transportation equipment, architectural components.

5754 H12 Aluminum

- H12 is lightly cold worked, with slightly higher strength than O state, retaining excellent ductility.

- Core Features: Slightly increased strength, good corrosion resistance, easy bending and stamping.

- Applications: Ship decks, piping, automotive panels, light machinery components.

5754 H14 Aluminum

- H14 is a medium-hard temper, cold worked to increase strength while maintaining adequate ductility.

- Core Features: Medium strength, good corrosion resistance, excellent formability.

- Applications: Ships, automobiles, roofing, storage tanks, industrial equipment.

5754 H114 Aluminum

- H114 is a low-hardness temper, suitable for light cold working, with high corrosion resistance but not high strength.

- Core Features: Low hardness, excellent corrosion resistance, easy processing.

- Applications: Ship hulls, chemical equipment, marine platform structures.

5754 O Aluminum

- O state is fully annealed, the softest temper, with the best ductility suitable for complex forming.

- Core Features: Lowest strength, excellent ductility, good corrosion resistance.

- Applications: Highly formed parts, stamped components, bent pieces, chemical and marine equipment.

5754 Aluminum Plate Chemical Composition Limits

| Elemant | Si | Fe | Cu | Mn+Cr | Mg | Zn | Ti | Others-Each | Others Total | Al Min |

| 5754 | 0.40 | 0.40 | 0.10 | 0.10-0.6 | 2.6-3.6 | 0.20 | – | 0.05 | 0.15 | Remainder |

Typical Mechanical Properties Data of Aluminum 5754

| Temper | Thickness | Yield Strength | Tensile Strength | Elongation | Hardness1) | |

| Param | Rp0.2 | Rm | A50 | A | ||

| [mm] | [N/mm2] | [N/mm2] | [%] | [%] | HBW | |

| 5754 O/H111 | > 0.2–0.5 | ≥ 80 | 190–240 | ≥ 12 | - | 52 |

| > 0.5–1.5 | ≥ 80 | 190–240 | ≥ 14 | - | 52 | |

| > 1.5–3.0 | ≥ 80 | 190–240 | ≥ 16 | - | 52 | |

| > 3.0–12.5 | ≥ 80 | 190–240 | ≥ 18 | - | 52 | |

| > 12.5–100.0 | ≥ 80 | 190–240 | - | ≥ 17 | 52 | |

| 5754 H112 | ≥ 6.0–12.5 | ≥ 100 | ≥ 190 | ≥ 12 | - | 62 |

| > 12.5–25.0 | ≥ 90 | ≥ 190 | - | ≥ 10 | 58 | |

| > 25.0–40.0 | ≥ 80 | ≥ 190 | - | ≥ 12 | 52 | |

| > 40.0–80.0 | ≥ 80 | ≥ 190 | - | ≥ 14 | 52 | |

| 5754 H12 | > 0.2–0.5 | ≥ 170 | 220–270 | ≥ 4 | - | 66 |

| > 0.5–1.5 | ≥ 170 | 220–270 | ≥ 5 | - | 66 | |

| > 1.5–3.0 | ≥ 170 | 220–270 | ≥ 6 | - | 66 | |

| > 3.0–6.0 | ≥ 170 | 220–270 | ≥ 7 | - | 66 | |

| > 6.0–12.5 | ≥ 170 | 220–270 | ≥ 9 | - | 66 | |

| > 12.5–40.0 | ≥ 170 | 220–270 | - | ≥ 9 | 66 | |

| 5754 H14 | > 0.2–1.5 | ≥ 190 | 240–280 | ≥ 3 | - | 72 |

| > 1.5–6.0 | ≥ 190 | 240–280 | ≥ 4 | - | 72 | |

| > 6.0–12.5 | ≥ 190 | 240–280 | ≥ 5 | - | 72 | |

| > 12.5–25.0 | ≥ 190 | 240–280 | - | ≥ 6 | 72 | |

| 5754 H16 | > 0.2–0.5 | ≥ 220 | 265–305 | ≥ 2 | - | 80 |

| > 0.5–6.0 | ≥ 205 | 265–305 | ≥ 3 | - | 80 | |

| 5754 H18 | > 0.2–0.5 | ≥ 250 | ≥ 290 | ≥ 1 | - | 88 |

| > 0.5–3.0 | ≥ 250 | ≥ 290 | ≥ 2 | - | 88 | |

| 5754 H22/H32 | > 0.2–0.5 | ≥ 130 | 220–270 | ≥ 7 | - | 63 |

| > 0.5–1.5 | ≥ 130 | 220–270 | ≥ 8 | - | 63 | |

| > 1.5–3.0 | ≥ 130 | 220–270 | ≥ 10 | - | 63 | |

| > 3.0–6.0 | ≥ 130 | 220–270 | ≥ 11 | - | 63 | |

| > 6.0–12.5 | ≥ 130 | 220–270 | ≥ 10 | - | 63 | |

| > 12.5–40.0 | ≥ 130 | 220–270 | - | ≥ 9 | 63 | |

| 5754 H24/H34 | > 0.2–1.5 | ≥ 160 | 240–280 | ≥ 6 | - | 70 |

| > 1.5–3.0 | ≥ 160 | 240–280 | ≥ 7 | - | 70 | |

| > 3.0–6.0 | ≥ 160 | 240–280 | ≥ 8 | - | 70 | |

| > 6.0–12.5 | ≥ 160 | 240–280 | ≥ 10 | - | 70 | |

| > 12.5–25.0 | ≥ 160 | 240–280 | - | ≥ 8 | 70 | |

| 5754 H26/H36 | > 0.2–1.5 | ≥ 190 | 265–305 | ≥ 4 | - | 78 |

| > 1.5–3.0 | ≥ 190 | 265–305 | ≥ 5 | - | 78 | |

| > 3.0–6.0 | ≥ 190 | 265–305 | ≥ 6 | - | 78 | |

| 5754 H28/H38 | > 0.2–1.5 | ≥ 230 | ≥ 290 | ≥ 3 | - | 87 |

| > 1.5–3.0 | ≥ 230 | ≥ 290 | ≥ 4 | - | 87 | |

5754 Aluminum Sheet Tolerance Chart

| Thickness | Tolerance Specified Width | ||

| Over | Including | ≤ 1250mm | > 1250mm ≤ 1600mm |

| ≥ 2.5mm | 4mm | ±.28mm | ±.28mm |

| 4mm | 5mm | ±.30mm | ±.30mm |

| 5mm | 6mm | ±.32mm | ±.32mm |

| 6mm | 8mm | ±.35mm | ±.40mm |

| 8mm | 10mm | ±.45mm | ±.50mm |

| 10mm | 15mm | ±.50mm | ±.60mm |

| 15mm | 20mm | ±.60mm | ±.70mm |

| 20mm | 30mm | ±.65mm | ±.75mm |

| 30mm | 40mm | ±.75mm | ±.85mm |

5754 Aluminum Properties

- Corrosion Resistance: Performs excellently in harsh environments such as seawater and industrial pollution.

- High Strength: 5754 is a high-strength alloy, providing good structural integrity and rigidity in load-bearing applications.

- Weldability: This alloy is easy to weld, which is beneficial for complex structures and maintenance.

- Formability: It can be processed through rolling, stretching, and bending.

- Low Density: Like most aluminum alloys, it is lightweight, which helps improve vehicle fuel efficiency.

5754 Aluminum Plate Advantages

| Advantage | Description |

| Excellent Corrosion Resistance | Due to its high magnesium content, 5754 aluminum plate exhibits outstanding corrosion resistance in marine environments, humid conditions, and chemical exposure. Particularly when exposed to saltwater, atmospheric moisture, or industrial pollutants, 5754 aluminum plate forms a dense oxide layer that effectively prevents corrosion and oxidation, extending its service life. As a result, it is widely used in shipbuilding, marine engineering, chemical storage tanks, and food processing equipment that require long-term corrosion resistance. |

| High Tensile Strength | 5754 aluminum plate has a higher tensile strength than general 5-series aluminum alloys, making it superior in bearing mechanical stress and structural loads. Compared to 5052 aluminum alloy, 5754 aluminum plate can achieve higher strength after cold working or heat treatment while maintaining good ductility and toughness. Therefore, it is commonly used in automotive manufacturing, railway vehicles, pressure vessels, and bridges where high material strength is essential to ensure structural safety and stability. |

| Excellent Weldability | 5754 aluminum plate supports various welding methods, including TIG, MIG, spot welding, and friction stir welding, while maintaining high strength and corrosion resistance after welding. This outstanding weldability makes it widely used in automotive manufacturing, shipbuilding, tanker construction, and high-speed rail carriages, where welded structural components are required. It improves processing efficiency while ensuring the quality and durability of welded joints. |

5754 Aluminum Plate Disadvantages

- 5754 aluminum plate has two disadvantages: it is not heat treatable and cannot be used for casting applications.

- Slightly stronger than 5052 alloy, but less ductile

5754 Aluminum Corrosion Resistance

5754 aluminum alloy is a stronger material than 5251 and has good machinability. Its main property is the alloy's ability to provide excellent resistance to seawater and industrial chemical corrosion.

5754 aluminum has excellent corrosion resistance and is especially suitable for harsh environments such as marine and humid conditions.

- Overall excellent corrosion resistance: performs exceptionally well in marine atmosphere and seawater environments.

- Strong resistance to stress corrosion cracking: suitable for welded structural components subjected to stress.

- Good weldability: the corrosion resistance of the weld zone does not significantly decrease after welding.

In practical applications, as long as direct contact with dissimilar metals is avoided and strong acid or strong alkali environments are prevented, 5754 aluminum can provide long-term and reliable corrosion protection.

Special corrosion forms to watch for with 5754 aluminum

Although 5754 aluminum has very good overall corrosion resistance, the following forms of localized corrosion should still be watched for under certain conditions:

Pitting corrosion:

In media containing chloride ions (Cl⁻), such as seawater or salt-spray environments, all aluminum alloys may experience pitting. However, 5754 aluminum has a strong oxide-film self-repair ability, giving it medium-to-high resistance to pitting. Pitting is usually shallow and develops slowly.

Intergranular corrosion:

After improper heat treatment or welding, if magnesium in the alloy precipitates continuously along grain boundaries in the form of the β phase (Al₈Mg₅), intergranular corrosion may occur. However, the magnesium content of 5754 aluminum (2.6–3.6%) is well-controlled and it is commonly used in the H temper (strain-hardened), making its susceptibility relatively low.

Stress corrosion cracking (SCC):

Conventional 5xxx series Al-Mg alloys (with magnesium content below 3.5%) exhibit very high resistance to stress corrosion cracking. The magnesium content of 5754 aluminum typically falls within this safe range, giving it excellent SCC resistance—one of the reasons it can be used for load-bearing structural components.

Galvanic corrosion (dissimilar metal contact corrosion):

This is a particularly important issue. When 5754 aluminum comes into direct contact with metals with a more noble potential, such as copper or steel, in the presence of an electrolyte (such as water), it will act as the anode and corrode more rapidly. In practical applications, insulating gaskets, coatings, or sealants should be used to isolate them.

Comparison of 5754 aluminum with other commonly used aluminum alloys

- 5754 vs. 3xxx series (Al-Mn, such as 3003): corrosion resistance is similar, both very good. However, 5754 has higher strength.

- 5754 vs. 6xxx series (Al-Mg-Si, such as 6061): in marine environments, 5754 generally has better corrosion resistance than 6061, especially in resistance to exfoliation corrosion. 6061 requires heat treatment (T6 temper) to achieve high strength, but this may reduce corrosion resistance.

- 5754 vs. 2xxx series (Al-Cu, such as 2024): far superior to the 2xxx series. Because of their copper content, the 2xxx alloys have poor corrosion resistance, especially in terms of pitting and intergranular corrosion, and usually require cladding with a high-purity aluminum layer (Alclad) for protection.

5754 Aluminum Plate Applications

5754 is widely used in welded structures, storage tanks, pressure vessels, ship structures and offshore facilities, transport tanks, and in applications requiring good processing properties, good corrosion resistance, high fatigue strength, high weldability, and moderate static strength.

5754 aluminum plate has rust resistance and excellent processability, so many automotive applications are very suitable for 5754 aluminum plate. Other industries that often use 5754 aluminum include:

- Marine and offshore structures: Hulls, superstructures, and other components exposed to seawater.

- Automotive components: Body panels, flooring, and other parts requiring good tensile properties.

- Industrial equipment: Frames, chemical processing equipment, and food processing machinery.

- Construction and decorative applications: Often anodized to enhance appearance and corrosion resistance.

- General engineering: Sheet metal parts, storage systems.

Popular application topics about 5754 aluminum plate

- 5754 h34 thick aluminium plate

- Aluminum plate alloy 5754 h111

- 5754 h114 aluminum tread plate

- 5754 aluminum deck plate

- 5754 aluminum plate 4.5mm

- Aluminum plate 40 mm 5754

- 5754 O H111 Oil Tanker Aluminum Sheet

- 5754 O Aluminum Sheet for Auto Body

- 5754 H111 H112 Marine Grade Aluminum Plate

- 5754 aluminum sheet for truck body

- 5754 aluminum plate tank truck tank material

- 5754 aluminum plate for storage tank bracket

- 5754 h114 five ribbed patterned plate

- 5754 aluminum plate for automotive parts

- 5754 aluminum plate pressure vessel

- 5754 aluminum plate for tank partition

- 5754 aluminum plate for cabinet

- Marine Grade 5754 Aluminum Hexagonal Bar

- 5754 Marine Grade Aluminum Square Bars

- 5754 Marine Grade Aluminum Round Bar

- 5754-H111 aluminum plate for the skin of box trucks

- 5754-H114 aluminum plate car carriage anti-skid plate

- 5754 aluminum plate for automotive fuel tank materials

- 5754 aluminum plate for power battery casing cover plate

- Engine protective cover 5754-O state aluminum plate roll

- 5754 patterned aluminum plate for anti slip of refrigerated carriages

- 5754 aluminum plate for high-speed rail sound insulation barrier

What is 5754 aluminum equivalent to?

5754 aluminum belongs to the magnesium-aluminum alloy category. Its corresponding grades include EN AW 5754 and AlMg3. It is closely related to other 5xxx series aluminum alloys (such as 5154, 5454), with the main differences concentrated in the specific content of alloying elements. The name "AlMg3" comes from the fact that this alloy contains approximately 3% magnesium.

EN AW 5754 is the corresponding European standard designation.

In terms of composition, magnesium (Mg) is the core alloying element of 5754 aluminum, playing a key role in enhancing material strength and corrosion resistance. In addition, a small amount of chromium (Cr) and manganese (Mn) is added to help magnesium perform better.

5754 Aluminum Alloy Grades and Common Names

- aa5754 aluminium

- 5754 aluminum

- aw 5754

- 5754 alloy

- 5754 aluminium alloy

- al 5754

- aluminium aw 5754

- aluminium 5754

Comparison of 5754 with Similar Alloys

| Comparison Target | Detailed Description |

| Compared to 5052 | 5754 aluminum plate has a higher magnesium (Mg) content than 5052 aluminum plate, giving it superior strength. Due to its higher magnesium content, 5754 aluminum plate exhibits better tensile strength and yield strength, providing stronger support when bearing heavy loads. Therefore, in applications requiring higher strength, such as automotive manufacturing, ship structures, and pressure vessels, 5754 aluminum plate is often a better choice than 5052. |

| Compared to 5083 | 5754 aluminum plate has a lower magnesium content than 5083 aluminum plate, resulting in lower overall strength. However, this lower magnesium content provides 5754 aluminum plate with better formability, making it ideal for applications requiring complex forming processes. In contrast, 5083 aluminum plate is better suited for high-strength and extreme environmental applications such as marine vessels and pressure vessels, while 5754 aluminum plate is preferred for automotive parts and structural components requiring good workability. |

| Compared to 5251 | 5754 aluminum plate has higher strength than 5251 aluminum plate, making it more advantageous in applications requiring higher mechanical strength. While 5251 aluminum plate offers good corrosion resistance and machinability, its tensile and yield strength are lower. In contrast, 5754 aluminum plate maintains excellent corrosion resistance while offering superior mechanical properties, making it more suitable for transportation, construction, and industrial equipment manufacturing. |

| Compared to 6061 | 5754 aluminum plate cannot be strengthened through heat treatment, whereas 6061 aluminum plate, a heat-treatable alloy, has significantly higher strength. However, 5754 aluminum plate offers superior corrosion resistance, especially in marine and humid environments, compared to 6061 aluminum alloy. Therefore, in applications requiring high corrosion resistance but moderate strength, such as ship components, chemical containers, and food processing equipment, 5754 aluminum plate is the preferred choice, while 6061 aluminum plate is more suitable for aerospace and high-strength mechanical components. |

5754 aluminum plate is highly regarded for its marine-grade corrosion resistance, formability, and weldability. It is an excellent choice for structural and aesthetic applications in harsh environments, offering a balance of moderate strength and exceptional manufacturing versatility.

5754 Aluminum Fabrication and Weldability

5754 aluminum has high formability, which means it can be easily rolled, bent, or cold-worked into various shapes and sizes.

Its excellent weldability (suitable for gas welding, arc welding, and resistance welding) further enhances its versatility in manufacturing, although it is not suitable for casting or heat treatment processes.

- Forming: Suitable for deep drawing, bending, and spinning.

- Machining: Use sharp tools; moderate machinability (can produce long chips).

- Welding: Avoid using 5xxx alloys with Mg content >3% in high-temperature applications (risk of sensitization).

- Surface Treatment: Anodizing, painting, or powder coating to enhance aesthetics/corrosion resistance.

5754 aluminum sheet is a versatile material known for its high corrosion resistance, good mechanical properties, and excellent formability. These characteristics make it the preferred material for demanding applications in the marine, automotive, and industrial sectors, where reliability and performance are critical.

5754 aluminum sheet FAQ

What is the difference between Aluminium 5754 and 5052?

The main differences between aluminum grades 5754 and 5052 lie in their alloy compositions, with 5754 having higher magnesium content for better corrosion resistance, while 5052 is stronger and more formable.

What is the difference between aluminium grade 5754 and 5251?

between 5754 and 5251, 5754 offers higher strength and better corrosion resistance, while 5251 is more formable and easier to weld.

What is the difference between 5754 and 5083 aluminum?

5754 vs 5083, 5754 has lower strength and better corrosion resistance, while 5083 is stronger and more suitable for marine applications.

Why is 5754 aluminum suitable for marine applications?

With its saltwater corrosion resistance, 5754 aluminum can withstand frequent exposure to marine environments without deteriorating or rusting.

Why is 5754 aluminum suitable for the automotive industry?

5754 aluminum has excellent tensile properties while maintaining high strength. It can be easily welded and anodized for an excellent surface finish. Because it is easy to form and process, this grade is ideal for doors, paneling, flooring, and other parts.

Products you may be interested in

- 5754 O Aluminum Plate Sheet

- 5754 H111 Aluminum Plate Sheet

- 5754 H22 Aluminum Plate Sheet

- 5754 H12 Aluminum Plate Sheet

- 5754 H14 Aluminum Plate

- 5754 H114 Aluminum Plate Sheet

- 5754 H24 Aluminum Plate Sheet

Further reading

Users viewing this material also viewed the following