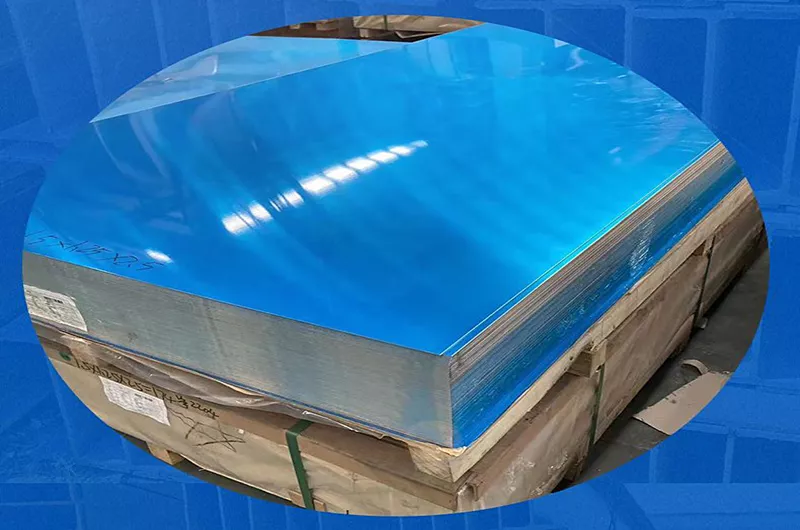

5005 h32 aluminum sheet plate

5005-H32 aluminum alloy is a 5xxx series aluminum-magnesium alloy containing 0.5%-1.1% magnesium. It has medium strength and good corrosion resistance, with a bright surface after anodizing and a color tone compatible with 6063 alloy. Its H32 temper represents a partially annealed work-hardened state, combining strength and plasticity.

- 5005: This is the alloy designation, representing its specific chemical composition.

- H32: This is the temper designation, indicating the mechanical properties achieved after specific processing and heat treatment.

5005 H32 aluminum alloy is a well-balanced, widely used medium-low strength rust-resistant aluminum. It combines good formability, weldability, and excellent anodizing performance, while the H32 temper ensures stable product performance. It is an economical and practical material choice for construction, home appliances, transportation, and other fields.

5005 H32 Aluminum Characteristics

- Medium strength: Higher than pure aluminum (e.g., 1100) and 3003 aluminum alloy, but lower than 5052 aluminum alloy.

- Excellent corrosion resistance: Particularly in marine and industrial atmospheric environments, it performs well. Better than 3003 alloy, belonging to the rust-resistant aluminum series.

- Good formability: Can be processed by stamping, drawing, and other methods.

- Outstanding anodizing effect: Forms a dense and aesthetically pleasing oxide layer, with good coloring properties, commonly used for decorative materials.

- Good weldability: Can be welded using various methods.

- Non-heat-treatable strengthening: Its strength cannot be significantly increased through "quenching + aging" like 6000 series alloys (e.g., 6061), mainly enhanced by cold working (work hardening).

Temper Designation: H32

"H" represents a work-hardened temper. The specific meaning of H32 is as follows:

H3: Indicates "low-temperature stabilization after work hardening."

Work hardening: The material is hardened through cold rolling, cold drawing, or similar processes, increasing its strength.

Low-temperature stabilization: After work hardening, the material is heated at a relatively low temperature (usually around 100-150°C). The purpose of this process is to stabilize the material's properties, partially relieve internal stresses generated during work hardening, and prevent property changes due to natural aging during subsequent storage or use, resulting in more stable mechanical properties and formability.

2: Indicates "1/4 hard" state, which is a strength level indicator, with tensile strength between full soft (O temper) and half hard (H14).

Therefore, H32 temper means the 5005 aluminum has reached 1/4 hardness through cold working, followed by low-temperature stabilization to achieve a product with stable properties.

5005 h32 aluminum sheet plate surface types

5005 h32 aluminum sheet and plate can have various finishes including mill finish, brushed, or anodized.

5005 h32 aluminum sheet plate Mechanical Property Limits

| Specified Thickness(in) | Tensile Strength - KSI | Elongationin 2 inches % | |||

| Ultimate | Yield | ||||

| Min | Max | Min | Max | ||

| 0.017 - 0.019 | 17 | 23 | 12 | - | 3 |

| 0.020 - 0.031 | 17 | 23 | 12 | - | 4 |

| 0.032 - 0.050 | 17 | 23 | 12 | - | 5 |

| 0.051 - 0.113 | 17 | 23 | 12 | - | 7 |

| 0.114 - 0.161 | 17 | 23 | 12 | - | 8 |

| 0.162 - 0.250 | 17 | 23 | 12 | - | 9 |

Chemical composition of 5005 aluminum sheet

- Aluminum Al: Balance

- Silicon Si: 0.3 Copper Cu: 0.2 Magnesium

- Mg: 0.5~1.1 Zinc Zn: 0.2

- Manganese Mn: 0.20 Chromium

- Cr: 0.10 Iron Fe: 0.7

Haomei 5005 h32 aluminum sheet plate stock

| Product | Width(In) | Length(In) |

| 1/32" 5005 H32 Aluminum Sheet 48"x120" | 48 | 120 |

| 1/32" 5005 H32 Aluminum Sheet 48"x144" | 48 | 144 |

| 0.040" 5005 H32 Aluminum Sheet 48"x120" | 48 | 120 |

| 0.040" 5005 H32 Aluminum Sheet 48"x144" | 48 | 144 |

| 0.050" 5005 H32 Aluminum Sheet 48"x120" | 48 | 120 |

| 0.050" 5005 H32 Aluminum Sheet 48"x144" | 48 | 144 |

| 1/16" 5005 H32 Aluminum Sheet 48"x120" | 48 | 120 |

| 1/16" 5005 H32 Aluminum Sheet 48"x144" | 48 | 144 |

| 0.063" 5005 H32 Aluminum Sheet 48"x120" | 48 | 120 |

| 0.063" 5005 H32 Aluminum Sheet 48"x144" | 48 | 144 |

| 0.090" 5005 H32 Aluminum Sheet 48"x120" | 48 | 120 |

| 0.090" 5005 H32 Aluminum Sheet 48"x144" | 48 | 144 |

5005 H32 Aluminum Applications

Due to its balanced properties, 5005 H32 is widely used in:

- Architectural decoration: Ceilings, wall panels, louvers, window and door frames, curtain wall panels, etc.

- Home appliance enclosures: Panels and shells for refrigerators, air conditioners, washing machines, etc.

- Vehicle interiors: Interior panels, luggage racks, etc., for cars and trains.

- Signage and lighting: Signs, lamps, etc., requiring good anodizing effects.

- Kitchenware and hardware: Kitchen utensils and hardware items that do not require high strength.

Architectural Decoration

5005 H32 aluminum alloy, with its resistance to atmospheric corrosion, ease of anodizing (customizable in popular colors like champagne gold, silver, etc.), and lightweight advantages, is widely used in window and door frames, curtain wall panels, ceiling keel components, etc. Compared with traditional steel or stainless steel materials, it can significantly reduce the overall building weight while meeting aesthetic and long-term weathering requirements, aligning with modern lightweight architectural design trends.

Home Appliance and Electronics

In components like refrigerator/air conditioner heat sinks, washing machine inner drums, and audio housings, 5005 H32 aluminum alloy provides excellent thermal conductivity for efficient heat dissipation, good formability for complex washing machine drum structures, and a polished appearance after surface treatment, enhancing the visual appeal of products like audio housings. It perfectly meets the dual needs of "functional practicality + refined appearance" in home appliances, making it a preferred material for lightweight appliances.

Transportation

For metro/light rail interior panels, bus handrails, small boat decks (non-heavy load areas), the lightweight characteristic of 5005 H32 aluminum alloy reduces energy consumption in rail vehicles, its corrosion resistance ensures long-term stability of components, and its weldability facilitates assembly, meeting transportation material requirements of "durable + easy to process."

Containers and General Applications

In scenarios such as drinking water tanks, lightweight chemical tanks, and toolboxes, 5005 H32 aluminum alloy ensures medium strength for impact resistance, corrosion resistance to safeguard stored materials, and the ability to be welded into integrated structures, successfully replacing some plastic or cast iron containers. It promotes the upgrade of containers toward "lightweight and durable" designs, reducing long-term usage costs.

5005 H32 Aluminum Machinability

- Formability: Medium, can be bent, curled, shallow stamped, but not suitable for deep drawing (for deep drawing, O temper or H112 temper is recommended).

- Machinability: Average; aluminum alloys are generally easier to machine than steel, but 5005 H32’s medium hardness requires suitable tools (e.g., high-speed steel, carbide tools).

- Surface treatment: Excellent; easy to anodize (forms uniform oxide film enhancing corrosion resistance and appearance), paint, or electrodeposit, suitable for high-appearance-demand applications.

5005 H32 Aluminum vs. Other Common Aluminum Alloys

- 5005 H32 vs. 3003 H14: 5005 H32 has slightly higher strength than 3003 H14. Due to magnesium content, it has better corrosion resistance (especially in marine environments) and anodized appearance.

- 5005 H32 vs. 5052 H32: 5052 has higher magnesium content (2.2%-2.8%), thus higher strength (especially fatigue strength) and corrosion resistance than 5005. 5052 H32 is a superior option but comes at higher cost.

- 5005 H32 vs. 6061 T6: 6061 is a heat-treatable alloy, with T6 strength far exceeding 5005 H32, but its formability and anodized appearance are inferior to 5005. They are applied in different fields.

5005 and 5052 belong to the 5xxx aluminum series and are often compared. The core differences between their H32 tempers are as follows, helping users choose:

| Comparison Dimension | 5005 H32 | 5052 H32 | Selection Suggestion |

| Magnesium Content | 0.5%-1.1% | 2.2%-2.8% | - |

| Tensile Strength | 170-210 MPa | 220-260 MPa | Choose 5052 for higher strength, 5005 for medium strength |

| Elongation | 8-12% | 7-10% | Choose 5005 if higher formability is required |

| Corrosion Resistance | Excellent (no copper interference) | Superior (high magnesium content but high purity) | Both suitable for ordinary environments; choose 5052 for highly corrosive environments (e.g., marine) |

| Cost | Lower (lower magnesium content, lower smelting cost) | Higher | Cost-sensitive applications with moderate performance, 5005 has an advantage |

| Main Applications | Architectural decoration, home appliance heat sinks | Marine, automotive structural parts, high-strength enclosures | - |

5005 H32 aluminum alloy is a "cost-performance oriented balanced material, " whose core value lies in achieving medium strength, good corrosion resistance, and processability at relatively low cost. It is particularly suitable for civil or industrial scenarios where performance requirements are not extreme but cost, appearance, and stability are important. When selecting, consider actual load, environmental corrosion, processing requirements, and compare with alloys like 5052, 6061 to ensure suitability for the application.

Related Questions about 5005-H32 Aluminum Sheet Plate

What is 5005 aluminum used for?

5005 aluminum is commonly used in architectural applications, automotive parts, and general manufacturing due to its good corrosion resistance and formability.

What is the difference between 5005 and 5052 aluminum?

5005 aluminum has lower strength but better formability and is often used for decorative applications, while 5052 aluminum offers higher strength and superior corrosion resistance, making it suitable for marine and high-stress applications.

What is the equivalent of aluminium 5005?

UNS A95005, Aluminium 5005, AA5005, Al5005, EN AW-5005

Products you may be interested in

- 5005 Aluminum Plate Sheet

- 5005 h34 aluminum sheet plate

- 5005 h14 aluminum sheet plate

- 5005 anodized aluminum sheet

Further reading