1070 Aluminum Strip

1070 aluminum strip belongs to the 1000 series of industrial pure aluminum products, with an aluminum content ≥99.7%, making it one of the higher-purity grades in the pure aluminum series.

1070 aluminum strip is renowned for its excellent electrical conductivity, outstanding corrosion resistance, and superior formability. As a non-heat-treatable alloy, its strength is improved through cold working rather than heat treatment, making it especially suitable for applications with extremely high requirements for conductivity and processing performance.

The core value of 1070 aluminum strip lies in its exceptional electrical properties, formability, and corrosion resistance rather than strength. When selecting this material, the key question to clarify is: does your application require good electrical/thermal conductivity or complex deep processing? If the answer is yes and strength requirements are not high, then 1070 aluminum strip is a very economical and appropriate choice. If higher strength is required, 1100, 3003, or other aluminum alloys should be considered.

Common Specification Range of 1070 Aluminum Strip (Customizable)

| Parameter | Range | Description |

| Thickness | 0.006mm (aluminum foil) ~ 6.00mm | Ultra-thin for electronic components; standard thickness for transformers, cables, etc. |

| Width | 10mm ~ 2000mm | Customized according to application scenarios, such as narrow strips for bottle caps and wide strips for transformers |

| Length | Custom cut-to-length as required, or supplied in coils | Coil supply is convenient for continuous processing |

| Tolerance | Thickness tolerance up to ±0.01mm, width tolerance ±1mm | Tighter tolerances available for high-precision products |

| Temper | O / H12 / H14 / H16 / H18 | (Custom tempers available upon request) |

1070 Aluminum Strip Tempers

- O temper (annealed): Softest condition with the best ductility, suitable for deep drawing.

- H14/H24 (half-hard): Provides a balance of strength and flatness, commonly used where both formability and rigidity are required, such as heat sinks.

- H18 (full-hard): Highest strength but lower ductility, commonly used for simple bending or applications where forming is not required.

1070 Aluminum Strip Properties

- Corrosion resistance: Easily forms a dense aluminum oxide film on the surface, performing well in normal atmosphere, fresh water, and most organic media

- Ductility: Extremely high ductility, easy to stretch, bend, and stamp

- Strength: Relatively low strength; not strengthened by heat treatment, but strength can be increased through cold working

- Weldability: Suitable for contact welding and gas welding, with good welding performance

- Machinability: Poor machinability; generally not used for components requiring complex machining

- Ultra-high purity (≥99.7% Al) with stable performance

- Excellent electrical and thermal conductivity, close to that of pure aluminum

- Soft texture and high ductility, easy to bend, stamp, and deep draw

- Smooth surface, suitable for further surface treatments

- Excellent formability: outstanding ductility and softness, highly suitable for deep drawing, spinning, and complex bending processes

- Non-heat-treatable: Strength is improved through cold working (strain hardening) rather than heat treatment

- High reflectivity: Good reflectance of light and heat

1070 Aluminum Strip Chemical Composition (Typical %)

| Element | Content (%) |

| Aluminum (Al) | ≥ 99.7 |

| Iron (Fe) | ≤ 0.25 |

| Silicon (Si) | ≤ 0.20 |

| Copper (Cu) | ≤ 0.04 |

| Zinc (Zn) | ≤ 0.04 |

| Others (Total) | ≤ 0.03 |

1070 Aluminum Strip Common Temper Properties

| Temper | Thickness(mm) | Tensile Strength Rm MPa | Yield Strength Rp0.2 MPa | Elongation % A50mm | Bend Radius | Hardness | |||

| 1070 O | 0.6 | min | max | min | max | min | 180° | 90° | / |

| 60 | 90 | 15 | 25 | 23 | Ot | Ot | 18 | ||

| 1070 H14 | 0.5-0.8 | 85 | 125 | 40 | 110 | 3 | / | / | 12 |

1070 Aluminum Strip Physical Parameters

Its physical properties are as follows:

- Density is 2.7g/cm³,

- The melting point is 1050℃,

- Boiling point is 2200℃,

- The softening temperature is 200°C.

1070 Aluminum Strip Tolerance Burr and Collapse

| The width of aluminum strip | Burr’s height | Collapsed side’s height |

| <0.2 | 0.01 | ≥0.05-0.1 |

| 0.2-1.0 | 0.015 | |

| 1.1-1.5 | 0.02 | |

| >1.6 | 0.03 |

Advantages and Disadvantages of 1070 Aluminum Strip

Advantages of 1070 Aluminum Strip:

- Excellent electrical and thermal conductivity.

- Outstanding processing performance, suitable for complex forming.

- Good corrosion resistance with a bright appearance.

- Low density, lightweight.

Disadvantages of 1070 Aluminum Strip:

- Very low strength; not suitable for load-bearing structural components.

- Low hardness; surface is prone to scratching.

Applications of 1070 Aluminum Strip

1070 aluminum strip / 1070 aluminum coil is a high-purity aluminum strip material that combines excellent electrical conductivity, thermal conductivity, formability, and corrosion resistance. This product is typically used in industrial applications that require high electrical performance and surface quality but do not demand high structural strength. It is one of the representative electrical aluminum strips and is widely used across multiple industries.

Power and Electrical Industry (Primary Application Area)

In power systems, 1070 aluminum strip for transformers is one of the most common application forms. Its stable electrical performance and good ductility make it an economical alternative to copper materials:

- Aluminum strip for transformer windings: Commonly supplied in HO / O temper, with a thickness range of approximately 0.2–3.0 mm, widely used in high- and low-voltage windings of dry-type and oil-immersed transformers

- Cables and electrical materials: Used for cable shielding layers, wire conductors, capacitor electrodes, and other conductive components

- Conductive busbars and connectors: Busbars, conductive strips, and various electrical connectors with high requirements for conductivity and processing consistency

Electronics and Packaging Industry

Benefiting from its high-purity aluminum characteristics, 1070 aluminum strip / aluminum foil stock is also well suited for applications in the electronics and packaging industries:

- Electronic heat dissipation components: Heat sinks, shims, isolation meshes, and other products with high thermal conductivity requirements

- Food and pharmaceutical packaging: Food packaging aluminum foil, pharmaceutical aluminum foil, and bottle cap stock; after anodizing, the surface brightness is high and color stability is excellent

- Deep-processed products: Suitable for aluminum cans, aluminum containers, and other products produced through deep drawing processes, with stable forming performance

Other Industrial Applications

- Heat exchangers and cooling systems: Used for heat exchangers, heat sinks, and related components, fully leveraging the advantages of high thermal conductivity aluminum strip

- Decorative and signage products: Decorative strips, nameplates, and similar products requiring good surface quality and corrosion resistance; uniform and attractive appearance after anodizing

- Chemical equipment components: Suitable for parts used in general corrosive environments, but not recommended for strong acid or strong alkali conditions

Comparison of 1070 Aluminum Strip with Similar Alloys

Among industrial pure aluminum and commonly used aluminum alloys, 1070 aluminum strip is typically positioned as a representative material with high conductivity, high purity, and stable performance. Compared with several common alloys, the differences are more reflected in application focus and industry practices rather than a simple distinction of “better” or “worse.”

Compared with 1060 Aluminum Strip

1060 aluminum has an aluminum content of no less than 99.6%, and its overall performance is very close to that of 1070, with slightly higher electrical conductivity (approximately 61.5% IACS). In practical applications, the two are highly interchangeable in the power and electrical fields. The specific choice usually depends on existing customer standards, certification requirements, or long-term usage habits rather than inherent performance differences.

Compared with 1050 / 1050A Aluminum Strip

1050 series aluminum strip has an aluminum content of approximately 99.5% and also belongs to industrial pure aluminum materials. Compared with 1070, it offers slightly higher strength, but its electrical and thermal conductivity are marginally lower. The application scenarios of the two are very similar, both being widely used in electrical, electronic, and general industrial processing fields. However, 1070 has a clear advantage in applications with higher conductivity requirements.

Compared with 1100 Aluminum Strip

1100 aluminum strip is a representative grade among industrial pure aluminum materials. With an aluminum content of approximately 99.0% and a small amount of copper added, its strength is significantly higher than that of 1070 while still maintaining good formability. However, due to the change in alloy composition, its corrosion resistance and electrical conductivity are slightly lower than those of 1070. 1100 is more commonly used for products requiring a certain level of strength and appearance quality, such as cookware, nameplates, and decorative components.

Compared with 3003 Aluminum Strip

3003 is an aluminum-manganese alloy and differs significantly from 1070 in material positioning. 3003 exhibits superior strength, formability, and corrosion resistance, but its electrical conductivity is far lower than that of industrial pure aluminum. The application fields of the two are clearly differentiated: 1070 is mainly used in power, electrical, and thermal conductivity-related applications, while 3003 is more suitable for chemical equipment, architectural sheets, and products with higher structural strength requirements.

Key Points for Selecting 1070 Aluminum Strip

When purchasing 1070 aluminum strip / 1070 aluminum coil, it is important to consider the specific application scenario and evaluate factors such as temper, composition, and specifications to ensure that material performance matches actual usage requirements.

First, select the appropriate temper based on the processing method and application requirements.

- For deep drawing or complex forming processes, O temper is recommended due to its superior ductility and lower risk of cracking.

- When a certain level of mechanical strength is required, H temper can be selected.

- For electrical applications such as transformer windings, HO temper is widely used as it balances electrical performance and processing stability.

Second, special attention should be paid to aluminum purity. High-quality 1070 aluminum strip should have an aluminum content of no less than 99.7%, which is the key basis for ensuring its electrical conductivity, thermal conductivity, and long-term performance stability.

In terms of specifications, thickness, width, and dimensional tolerance requirements should be clearly defined in advance. For precision applications in electrical and electronic fields, higher requirements are often placed on thickness uniformity and edge quality, which usually necessitate customized production.

In addition, it is recommended to prioritize reputable manufacturers that comply with national or industry standards to ensure consistent chemical composition, mechanical properties, and batch-to-batch stability, thereby avoiding potential issues in subsequent processing or use caused by quality fluctuations.

With its excellent electrical and thermal conductivity, good formability, and stable material quality, 1070 aluminum strip continues to hold irreplaceable application value in the power, electrical, electronics, and packaging industries. It is an industrial base material that balances performance advantages with cost efficiency.

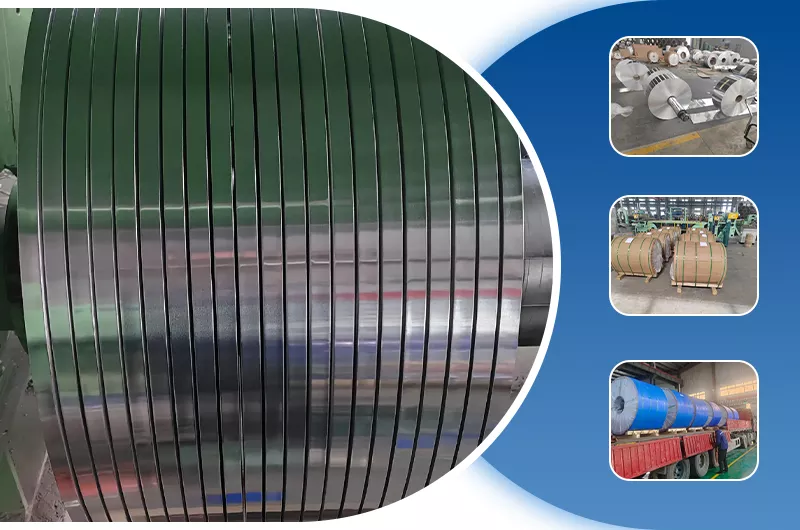

Haomei Aluminum supplies 1070 aluminum strip and aluminum coil in various thicknesses, widths, and tempers, offering factory-direct pricing and a stable quality control system. OEM customization and bulk orders are also supported to meet the long-term procurement needs of different customers.

Further reading

Users viewing this material also viewed the following