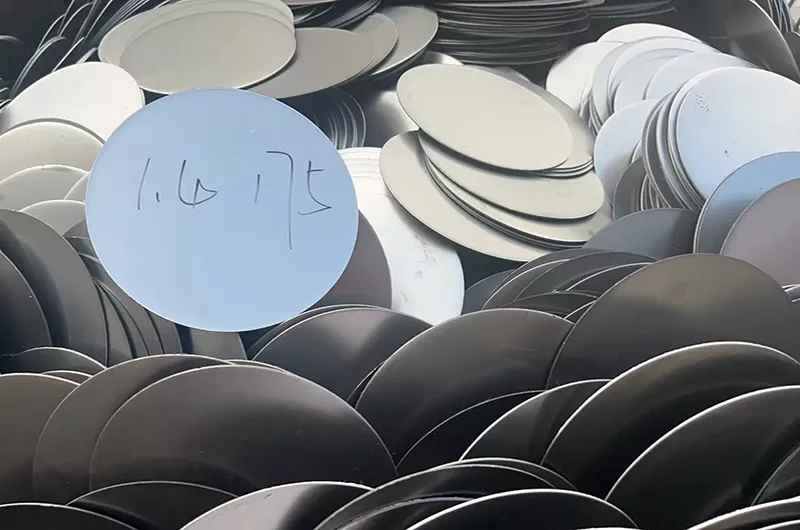

1070 Aluminum Disc Circle

1070 aluminum disc circles are circular aluminum products made from 99.7% purity industrial pure aluminum (1070 aluminum alloy, UNS A91070) through shearing or stamping. They belong to the 1000 series high-purity aluminum products and retain the excellent electrical conductivity, thermal conductivity, corrosion resistance, and formability of pure aluminum. They are widely used in industries such as cookware, electronics, and packaging.

Compared with the more common 1050 aluminum alloy, 1070 aluminum alloy has slightly higher purity, which means it offers better corrosion resistance and electrical/thermal performance, but slightly lower hardness.

1070 Aluminum Disc Circle Specifications

| Property | Detail |

| Alloy | 1070 |

| Temper | O, H12, H14, H16 , H18(customizable) |

| Thickness | 0.2–6.0 mm (can be customized) |

| Diameter | 100–1600 mm, custom diameters available |

| Surface | Bright, matte, brushed, anodized, rolled, PE/PVC film protection, etc. |

| MOQ | 1–3 tons |

| Edge | Smooth, burr-free, mill finish, bright, anodized, or polished suitable for deep processing |

| Standard | ASTM B209, JIS H4000, EN 485-2 (depending on market) |

1070 Aluminium Circle Diameter Tolerance

| Nominal Diameter | Tolerance |

| Multiple of 5mm | +/- 0.5mm |

| Not multiple of 5mm | +/- 3.0mm |

1070 Aluminum Disc Circle Features

- High corrosion resistance: suitable for environments with extremely high oxidation resistance requirements.

- Low strength: cannot be strengthened by heat treatment, but strength can be improved through cold working.

- Excellent formability: very suitable for deep drawing and spinning. It can be drawn into deep containers without cracking.

- High thermal conductivity: thermal conductivity is approximately 6230 W/(m·K), providing excellent heat dissipation performance.

- Electrical conductivity: good electrical conductivity, with conductivity of approximately 62% IACS (International Annealed Copper Standard).

- High reflectivity: high surface gloss, suitable for lighting and decorative applications.

- Purity: aluminum content is at least 99.7%.

- Appearance: can be polished, coated, or anodized to achieve different surface finishes.

1070 Aluminum Disc Circle Production Methods

CC (Continuous Casting): typically used for standard industrial applications.

DC (Direct Chill Casting): suitable for high-quality deep drawing or anodizing, as it provides a finer grain structure and fewer surface defects.

The choice depends on whether you prioritize cost (CC) or forming quality (DC).

CC vs. DC 1070 Aluminum Circles

| Feature | CC (Continuous Casting) | DC (Direct Chill / Hot Rolled) |

| Production Process | Molten metal is cast directly into a coil. Skips the hot-rolling stage. | Molten metal is cast into ingots, then hot-rolled into sheets. |

| Microstructure | Coarser grain structure; higher risk of impurities. | Fine, uniform grain structure (equiaxed grains). |

| Deep Drawing | Average; prone to "earing" or cracking if drawn deep. | Excellent; ideal for deep pots and complex shapes. |

| Surface Quality | Standard; may show slight "orange peel" after forming. | Superior; smooth, high-gloss, and consistent. |

| Anodizing | Can be patchy or uneven. | Ideal for anodizing (no color difference). |

| Cost | Lower (more economical). | Higher (due to extra processing). |

CC 1070 Aluminum Circle

- Best use: shallow drawing parts or flat applications where cost is the primary consideration.

- Applications: shallow trays, lampshades, traffic signs, and decorative discs.

- Advantages: cost-effective and short production cycle.

- Disadvantages: not suitable for extreme drawing; surface quality may not achieve a perfect high-end mirror polish.

DC 1070 Aluminum Circle

- Best use: high-end cookware and industrial components requiring extreme deformation.

- Application fields: pressure cookers, deep-drawn stock pots, high-end reflectors, and electronic housings.

- Advantages: high elongation (better ductility), stable mechanical properties, and excellent anodizing appearance.

- Disadvantages: more expensive than CC.

Which one should you choose?

- If you manufacture low-cost cookware (such as simple frying pans) or products that do not require deep drawing or high-end surface finishing, choose CC.

- If you produce high-end cookware, require deep drawing (depth > 10 cm), or plan to anodize the final product to achieve a professional-grade surface finish, choose DC.

1070 Aluminum Circle Applications

Due to its high purity, 1070 aluminum alloy discs (aluminum circles) are softer and easier to form than 3000 or 5000 series aluminum alloys, making them an ideal choice for applications requiring extreme deformation or high surface reflectivity.

- Cookware: pots, pans, and lids.

- Cosmetics: packaging, perfume sprayers, and aerosol cans.

- Electronics: LED lamp housings, reflectors, and capacitor components.

- Industrial: electrical components, heat sinks, and signage. Common uses

- Deep drawing products: items requiring significant forming, such as bowls, reflectors, and housings.

- Cookware and tableware: due to excellent thermal conductivity and formability.

- Decorative and lighting products: polished or coated to enhance appearance.

- Plasticity priority (deep drawing, spinning, cold extrusion): choose 1070 O temper, which offers the highest elongation and minimal risk of cracking during forming.

- Strength / flatness priority (reflectors, traffic signs): choose 1070 H14 / H16 / H18, work-hardened tempers with good deformation resistance and excellent surface polishing results.

- Thermal / electrical conductivity priority (heat sinks, busbars): 1070 O temper is preferred, as annealed pure aluminum provides the best thermal and electrical performance.

- Weather resistance / corrosion resistance requirements: for almost all outdoor or chemically exposed applications, anodizing, painting, or coating is required.

Cookware and Kitchenware

The most common application of 1070 aluminum alloy circles is the production of household and commercial kitchenware. Its high thermal conductivity ensures uniform heating.

- Deep drawing products: rice cooker inner pots, pressure cookers, and deep-bottom frying pans. Its high elongation (up to 35%) enables complex deep drawing without cracking.

- Spinning applications: kettles, basins, and pot lids. This material is relatively “soft” and easy to form on a rotating mandrel.

- Non-stick cookware base: commonly used as the substrate for non-stick frying pans, followed by coating with polytetrafluoroethylene (PTFE) or ceramic coatings.

- Pearl anodized cookware: due to its high purity, anodizing produces a very clean and bright surface, making it suitable for high-end kitchen decoration.

| Specific Application | Specification (Thickness / Diameter) | Temper |

| Deep drawing (rice cooker inner pots, pressure cookers, deep-bottom frying pans) | Thickness: 0.8–2.0 mm Diameter: customized according to finished product size (e.g., rice cooker inner pot disc diameter is typically 150–300 mm) | O temper (annealed soft) |

| Spinning (kettles, basins, pot lids) | Thickness: 0.5–1.5 mm Diameter: 100–400 mm | O temper or H12 (semi-hard) |

| Non-stick cookware base material | Thickness: 0.8–1.8 mm Diameter: 180–320 mm | O temper or H14 (semi-hard) |

| High-end decoration (bright anodized cookware) | Thickness: 1.0–2.0 mm Diameter: customized | O temper |

Lighting and Reflectors

1070 aluminum is highly favored in the lighting industry due to its high reflectivity and excellent heat dissipation performance.

- Luminaire reflectors: used for LED lighting, high-bay industrial lighting, and street lights. Its smooth surface can be polished to a mirror finish.

- Heat sinks: high thermal conductivity makes these discs ideal bases for LED modules, effectively dissipating heat generated by electronic components.

- Lampshades: decorative and functional shades for downlights and industrial lighting.

| Specific Application | Specification (Thickness / Diameter) | Temper |

| Luminaire reflectors (LED, industrial high-bay lights, street lights) | Thickness: 0.3–1.0 mm Diameter: 80–250 mm | H14 (semi-hard) or H16 (hard) |

| LED heat sinks | Thickness: 0.5–1.2 mm Diameter: 50–150 mm | O temper or H12 (semi-hard) |

| Decorative / functional lampshades | Thickness: 0.4–0.8 mm Diameter: customized | H14 (semi-hard) |

Electrical and Electronics

Due to its electrical conductivity (approximately 62% IACS), 1070 aluminum is a more economical choice than copper for certain electronic housings and components.

- Capacitor housings: aluminum discs are formed into impact-extruded housings through cold extrusion, used in the manufacture of electrolytic capacitors.

- Electromagnetic interference (EMI) shielding: used as substrates or covers to protect sensitive electronic components from electromagnetic interference.

- Busbars and connectors: used in power transmission systems where weight reduction is prioritized over maximum strength.

| Specific Application | Specification (Thickness / Diameter) | Temper |

| Capacitor housings (cold extrusion forming) | Thickness: 1.0–2.5 mm Diameter: 30–80 mm | O temper (annealed soft) |

| Electromagnetic interference (EMI) shielding (substrates / covers) | Thickness: 0.2–0.5 mm Diameter: customized | H14 (semi-hard) |

| Busbars / connectors (lightweight power transmission) | Thickness: 1.0–3.0 mm Diameter: 100–300 mm | H12 (semi-hard) or H14 (semi-hard) |

Industrial and Commercial Signage

- Traffic signs: round aluminum discs are used as substrates for road signs (stop, yield, speed limit). They are corrosion-resistant, ensuring decades of service life in outdoor environments.

- Nameplates and dials: used for industrial machinery labels, clock faces, and equipment control panels, as their surfaces are highly suitable for etching and printing.

| Specific Application | Specification (Thickness / Diameter) | Temper |

| Traffic signs (stop, yield, speed limit signs) | Thickness: 0.8–1.5 mm Diameter: 300 / 600 / 900 mm (commonly used standard sizes) | H18 (full hard) |

| Nameplates / dials (industrial machinery, clock faces, control panels) | Thickness: 0.3–0.8 mm Diameter: 20–100 mm | O temper or H12 (semi-hard) |

Industrial Packaging and Containers

- Aerosol and spray cans: used as the primary “slug” for impact extrusion to manufacture seamless aluminum bottles for cosmetics, pharmaceuticals, and household chemicals.

- Collapsible tubes: used in the production of toothpaste and medical ointment tubes.

| Specific Application | Specification (Thickness / Diameter) | Temper |

| Aerosol / spray cans (cosmetics, pharmaceuticals, household chemicals) | Thickness: 1.5–3.0 mm (as extrusion slugs) Diameter: 40–80 mm | O temper (annealed soft) |

| Toothpaste / medical ointment tubes | Thickness: 0.2–0.5 mm Diameter: 20–50 mm | O temper or H12 (semi-hard) |

Other Aluminum Circle Applications

| Series | Alloy | Characteristics | Typical Applications |

| 1 series | 1050 | Aluminum content not less than 99.5%, very high cost performance, excellent thermal conductivity. | Ordinary kitchen sinks, plates, daily household utensils. |

| 1060 | Aluminum content not less than 99.6%, excellent electrical and thermal conductivity and reflectivity. | LED lamp reflectors, heat dissipation base plates, chemical gaskets. | |

| 1070 | Higher purity, extremely high brightness after surface anodizing. | High-end reflectors, decorative parts, electronic bus bars. | |

| 1100 | Contains a small amount of copper, slightly higher strength than 1060, attractive surface appearance. | Deep-drawn cookware, printed photosensitive plates, gifts. | |

| 3 series | 3003 | Manganese added, about 20% higher strength than 1 series, strong corrosion resistance. | Non-stick cookware substrates, rice cooker inner pots, pressure cookers. |

| 3004 | Higher strength than 3003, greater hardness, good compressive resistance. | High-end cookware, lamp holder components, thin-wall deep-drawn parts. | |

| 3005 | Good corrosion resistance, excellent paint coating adhesion. | Color-coated aluminum circles, architectural decorative components. | |

| 3105 | Moderate strength, often produced with recycled material, environmentally friendly and economical. | Simple cookware, sunshades, decorative spinning parts. | |

| 5 series | 5052 | Medium to high strength, fatigue resistant, excellent salt spray corrosion resistance. | Traffic signs, aviation fuel tank components, high-end enclosures. |

| 5754 | Excellent weldability, outstanding resistance to industrial and marine corrosion. | Marine equipment, chemical containers, automotive structural parts. | |

| 5083 | The strongest alloy in the 5 series, outstanding low-temperature performance. | Pressure vessels, LNG tank components, military parts. | |

| 8 series | 8011 | Good stamping consistency, balanced tensile strength, low earing rate. | Anti-counterfeit bottle caps, pharmaceutical bottle seals, sealing lids, shallow drawn cups. |

Mechanical Properties of 1070 Aluminum Discs

| performance indicators | value |

| Density | 2.7 g/cm3 |

| Tensile strength | ≥70 MPa |

| Tensile strength | ≥35 MPa |

| Elongation | ≥30% |

| Coefficient of thermal expansion | 23.5×10-6/K |

| Thermal conductivity | 222 W/(m·K) |

| Conductivity | 63% IACS |

Chemical Composition of 1070 Aluminum Alloy Discs

| Alloy | Min. AL | Si | Fe | Cu | Mn | Mg | Ni | Zn | V | Other |

| 1050 | 99.5 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.05 | 0.03 |

| 1060 | 99.6 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.05 | 0.03 |

| 1070 | 99.7 | 0.25 | 0.25 | 0.04 | 0.03 | 0.03 | - | 0.04 | 0.05 | 0.03 |

| 1100 | 99 | 0.95 | 0.95 | 0.05-0.2 | 0.05 | - | - | 0.1 | - | 0.05 |

| 3003 | 96.75 | 0.7 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.15 |

Advantages and Limitations of 1070 Aluminum Disc Circles

Advantages of 1070 Aluminum Circles

- High purity: 99.7% aluminum content, stable and reliable performance.

- Excellent electrical conductivity: approximately 62% of copper, offering better cost performance.

- Superior thermal conductivity: fast and uniform heat transfer, energy-efficient.

- Outstanding formability: excellent deep drawing performance, suitable for complex shapes.

- Good corrosion resistance: protected by a natural oxide film, corrosion-resistant even without additional coatings.

- Lightweight: density is only one-third that of steel, reducing product weight and transportation costs.

- Good surface finish: suitable for anodizing and coating treatments.

- Easy to form and weld: easy to process and resistant to cracking.

- Environmentally friendly and recyclable: 100% recyclable, meeting sustainability requirements.

Limitations of 1070 Aluminum Circles

- Relatively low strength: lower than alloy aluminum (such as 3003 and 5052), not suitable for high-strength structural components.

- Low hardness: prone to scratching, surface protection is required.

- Not suitable for high-temperature environments: long-term service temperature is recommended not to exceed 100 °C.

- Average machinability: requires special cutting tools and processing techniques.

Comparison of 1070 Aluminum Circles with Similar Products

| Product | Aluminum Content | Electrical Conductivity | Strength | Deep Drawability | Typical Applications |

| 1070 Aluminum Disc Circle | 99.7% | Excellent | Low | Outstanding | Cookware, electronics, applications requiring high electrical conductivity |

| 1060 Aluminum Disc Circle | 99.6% | Close to 1070 | Close to 1070 | Outstanding | General alternative, slightly lower cost |

| 3003 Aluminum Disc Circle | 98% + Mn | About 60% IACS | Higher | Good | Structural parts, containers requiring higher strength |

| 5052 Aluminum Disc Circle | 97% + Mg | About 45% IACS | High | Moderate | Applications requiring high corrosion resistance |

Leveraging its high-purity aluminum characteristics, 1070 aluminum disc circles demonstrate unique advantages in applications with high performance requirements, especially in the cookware and electronics industries, where they have become one of the preferred materials. By selecting the appropriate temper, specifications, and surface treatment according to specific application needs, their performance advantages can be fully utilized to achieve optimal cost performance.

1070 Aluminum Disc Circle Selection and Purchasing Guide (Haomei Aluminum Professional Recommendations)

To help customers efficiently find the most suitable 1070 aluminum disc circles, we recommend considering the following aspects:

Clarify processing requirements

Deep drawing processing: for deep-drawn products such as cookware and containers, it is recommended to choose 1070 aluminum disc circles in O temper (annealed), which offer the best plasticity and elongation to ensure smooth stamping and forming.

Shallow stamping or higher strength requirements: if the product requires a certain level of strength, H12, H14, and other semi-hard tempers can be selected to balance strength and workability.

Determine specific specifications

Clearly define the required thickness, diameter, and processing tolerances to ensure dimensional accuracy of the 1070 aluminum discs during subsequent stamping, drawing, or welding processes, thereby reducing production risks.

Surface treatment requirements

Select surface treatments according to the application environment, such as polishing, anodizing, or protective films, which not only enhance appearance but also improve corrosion resistance and durability.

Temper selection:

- Deep-drawn cookware: O or H14 temper is preferred to ensure good formability.

- Structural support components: choose H16 or H18 temper to improve strength.

- Welded parts: O temper offers the best welding performance.

Thickness selection:

- Thin tableware: 0.4–0.8 mm

- Cookware body: 1.0–2.5 mm

- Thick-bottom cookware: 2.0–3.0 mm (composite cookware base structure)

Surface treatment:

- Cookware: anodizing or non-stick coating is recommended to improve wear resistance and ease of cleaning.

- Electronic components: maintain mill finish or apply conductive oxidation treatment.

- Decorative parts: brushing, sandblasting, or colored coatings are available.

Quality evaluation:

- Surface: free of scratches, oil stains, and oxidation spots; burr-free edges.

- Dimensions: diameter tolerance ≤ ±0.5 mm, thickness tolerance ≤ ±0.05 mm.

- Performance: complies with the mechanical property requirements specified by applicable standards.

Haomei Aluminum can provide 1070 aluminum disc circles with customized specifications, surface treatments, and various tempers according to customer requirements, ensuring that each batch meets precise needs, with fast delivery and reliable quality assurance.

Further reading

Users viewing this material also viewed the following