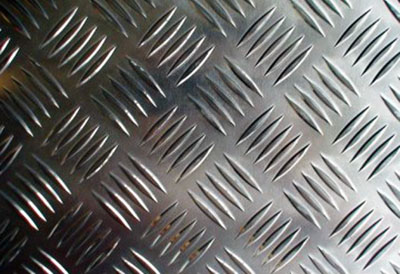

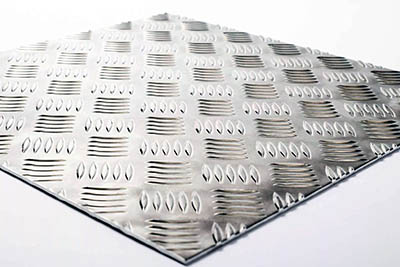

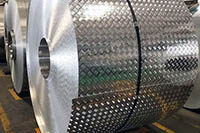

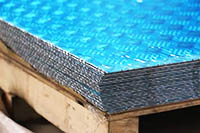

Polished aluminum diamond plate is created by rolling aluminum into thin sheets, then forming a diamond-shaped embossed pattern on one side, and finally polishing it. The polishing process enhances the surface smoothness of the aluminum diamond plate, giving it a shiny and reflective appearance.

"Polished Aluminum Diamond Plate" is a special type of metal sheet made from aluminum alloy, with a raised diamond pattern pressed on the surface and further polished. It combines anti-slip performance, metallic texture, and decorative appeal, making it widely used in industries, transportation, construction, and home applications.

Polished aluminum diamond plate uses pure aluminum or aluminum alloys (such as 3003, 5052 series) as the base material. Through cold rolling or hot rolling processes, regular raised diamond patterns are pressed on the surface, followed by mechanical polishing, chemical polishing, or electrolytic polishing treatment, resulting in a mirror-like or matte luster. The final product is a composite sheet with both "functional anti-slip + decorative gloss."

Features of Polished Aluminum Diamond Plate

- Excellent Anti-Slip Performance: The raised diamond pattern increases the surface friction coefficient, effectively preventing people or equipment from slipping even in wet or oily environments (such as workshop floors or ship decks), ensuring high safety.

- High Strength and Lightweight: The aluminum alloy base material (especially the 5052 series) combines high strength with low density (about 2.7g/cm³), making it about 1/3 lighter than steel plates of equivalent strength. This makes it convenient for handling, installation, and weight reduction needs (such as vehicle flooring).

- Outstanding Corrosion Resistance: The naturally formed oxide film (Al₂O₃) on the aluminum surface resists atmospheric, freshwater, and mild acid-alkali corrosion. For enhanced weather resistance, additional anodizing or coating treatments can be applied, making it suitable for outdoor or humid environments.

- High Aesthetic Appeal: After polishing, the surface displays a uniform luster (mirror polishing can achieve more than 90% reflectivity). The combination of regular diamond patterns with metallic gloss delivers both an industrial and modern aesthetic, and can be used as a substitute for stainless steel in decorative scenarios.

- Easy to Clean and Maintain: The polished surface is smooth and non-stick, and can be easily cleaned with water or neutral detergents. With no hygiene dead corners and rust resistance, its service life can reach 10–20 years (depending on the environment).

Material Options and Common Specifications of Polished Aluminum Diamond Plate

The performance and application scenarios of polished aluminum diamond plate mainly depend on the aluminum alloy grade, sheet thickness, pattern specifications, and polishing process.

| Category | Common Options | Characteristics and Application Scenarios |

| Aluminum Alloy Grade | 1050 Pure Aluminum | High purity (above 99.5%), excellent ductility, outstanding polishing effect, but relatively low strength; suitable for decorative panels and light load-bearing scenarios (such as display racks). |

| 3003 Aluminum Alloy (Al-Mn Alloy) | Contains manganese, providing better rust resistance than pure aluminum, medium strength, and high cost-effectiveness; suitable for humid environments (such as kitchen floors, cold storage flooring) and general industrial platforms. | |

| 5052 Aluminum Alloy (Al-Mg Alloy) | Contains magnesium, offering high strength (about 1.5 times that of 3003) and excellent corrosion resistance, capable of withstanding medium loads; suitable for vehicle flooring, ship decks, and heavy-duty platforms. | |

| Sheet Thickness | Base thickness: 1.0–8.0mm (commonly 1.5–5.0mm); pattern height: 0.5–2.0mm | Thickness ≤2.0mm: suitable for decorative walls, light steps; Thickness 2.0–5.0mm: suitable for flooring, platforms, vehicle flooring; Thickness >5.0mm: suitable for heavy-duty equipment bases. |

| Diamond Pattern Specification | Pattern side length: 25mm×25mm, 30mm×30mm, 50mm×50mm; pattern spacing: 5–10mm | Small side length (25–30mm): stronger anti-slip effect, suitable for high-footfall areas (such as stair treads); Large side length (50mm): better aesthetics, suitable for large-area flooring or wall applications. |

| Polishing Process | Mechanical Polishing | Low cost, surface shows matte or semi-mirror effect (roughness Ra≤0.8μm); suitable for industrial scenes or decoration with lower gloss requirements. |

| Chemical Polishing | High surface uniformity, better gloss than mechanical polishing (Ra≤0.2μm); suitable for moderate decorative needs (such as commercial counter panels). | |

| Electrolytic Polishing | Best mirror effect (Ra≤0.02μm), scratch-free surface, enhanced corrosion resistance; suitable for high-end decoration (such as hotel walls, display cabinets). |

Polished Aluminum Diamond Plate Materials

Common alloys used for polished aluminum diamond plate include 3003, 4017, and 6061.

-

Good formability and weldability.

Fair corrosion resistance, suitable for humid environments.

Has moderate strength, typically used for non-structural applications.

-

Higher strength and hardness, suitable for bearing larger loads.

Good corrosion resistance, suitable for various environments.

Exhibits good impact resistance and wear resistance.

-

High strength and corrosion resistance.

Its strength significantly increases after heat treatment.

Commonly used in applications requiring high strength.

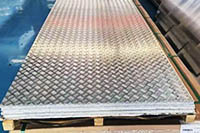

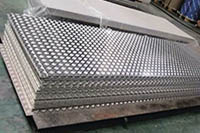

Polished Aluminum Diamond Plate Specifications and Sizes

Polished diamond aluminum plates are available in various specifications and sizes, with thickness typically ranging from 1/16" to 1/2". Width and length can be customized according to customer requirements. Common sizes include: 4x8, 4x10, etc.

Thickness Options for Diamond Tread Aluminum Sheet Plate

- .063"(1/16") diamond tread aluminum plate

- .100" diamond tread aluminum plate

- .125"(1/8") diamond tread aluminum plate

- .188"(3/16") diamond tread aluminum plate

- .250"(1/4") diamond tread aluminum plate

- .375"(3/8") diamond tread aluminum plate

- .500"(1/2") diamond tread aluminum plate

Selection of Tread Aluminum Sheet Plate Specifications

- 1' x 1' (12 x 12) diamond tread aluminum plate

- 1' x 2' (12 x 24) diamond tread aluminum plate

- 1' x 4' (12 x 48) diamond tread aluminum plate

- 1' x 10' (12 x 120) diamond tread aluminum plate

- 1.5' x 10' (18 x 120) diamond tread aluminum plate

- 2' x 2' (24 x 24) diamond tread aluminum plate

- 2' x 4' (24 x 48) diamond tread aluminum plate

- 2' x 5' (24 x 60) diamond tread aluminum plate

- 2' x 6' (24 x 72) diamond tread aluminum plate

- 2' x 8' (24 x 96) diamond tread aluminum plate

- 2' x 10' (24 x 120) diamond tread aluminum plate

- 3' x 3' (36 x 36) diamond tread aluminum plate

- 3' x 4' (36 x 48) diamond tread aluminum plate

- 3' x 10' (36 x 120) diamond tread aluminum plate

- 4' x 4' (48 x 48) diamond tread aluminum plate

- 4' x 8' (48 x 96) diamond tread aluminum plate

- 4' x 10' (48 x 120) diamond tread aluminum plate

- 5' x 8' (60 x 96) diamond tread aluminum plate

Other Popular Aluminum Diamond Plate Finish Options

-

Red aluminum diamond tread plate

-

Grey aluminum diamond tread plate

Haomei Aluminum Tread Plate Pattern Design

Application Fields of Polished Aluminum Diamond Plate

Thanks to its combined advantages of "anti-slip + aesthetics + lightweight, " polished aluminum diamond plate is widely applied across multiple industries.

Industrial and Storage Fields

- Workshop floors, operation platforms: anti-slip and oil-resistant, convenient for forklift and equipment movement (such as in machining plants, food processing factories)

- Stair treads, maintenance passages: diamond patterns prevent personnel from slipping, lightweight for easy installation on steel structures or equipment

- Shelves, pallet panels: high strength to carry goods, rust resistance prevents cargo from damp contamination (such as in cold storage, chemical warehouses).

Transportation Sector

- Vehicle flooring: such as truck beds, RVs, bus floors; lightweight reduces fuel consumption, while anti-slip ensures passenger safety

- Ship decks, yacht interiors: seawater corrosion resistance, polished surface enhances interior texture (such as yacht decks, ship passages)

- Rail transit components: such as metro or light rail maintenance platforms or equipment covers, rust-resistant and easy to maintain.

Construction and Decoration Fields

- Wall and ceiling decoration: mirror-polished plates can replace stainless steel in malls and hotels, enhancing space brightness

- Outdoor landscaping facilities: such as park walkways, terrace flooring; strong weather resistance with both anti-slip and aesthetic value

- Commercial counters, display racks: such as jewelry counters, product stands; polished surface adds a premium feel and rust resistance extends service life.

Home and Residential Use

- Garage flooring, entrance steps: anti-slip and easy to clean, preventing mud and sand brought in by vehicles

- Cabinets, furniture panels: such as kitchen hanging cabinet panels, wardrobe side panels; metallic texture enhances home style (industrial or modern)

- Bathroom anti-slip mats: cut into small pieces for bathroom floors, rust-resistant and easier to clean than traditional rubber mats.

Key Points and Precautions for Purchasing Polished Aluminum Diamond Plate

- Select material as needed: choose 5052 aluminum alloy for load-bearing scenarios, 1050 pure aluminum for decorative purposes, and 3003/5052 alloys for humid environments.

- Inspect polishing quality: high-quality polished plates should have no scratches, no color differences; mirror-polished plates can be checked through reflections (uniform and distortion-free images).

- Confirm pattern integrity: raised pattern height should be consistent, without dents, deformation, or burrs on the edges (can be checked by hand).

- Pay attention to dimensional tolerances: thickness, length, and width deviations should meet standards to avoid affecting installation precision.

- Avoid heavy impact: aluminum has lower hardness than steel; avoid direct impacts or long-term overloading (such as frequent rolling of heavy trucks) to prevent pattern deformation or sheet cracking.

Polished aluminum diamond plate is a metal material that combines "functionality and aesthetics." Its selection, installation, and maintenance should be based on the specific requirements of the application scenario (such as load-bearing, environment, or decorative style) to maximize its advantages.

Aluminum Diamond Plate Polishing Process

- Polishing Treatment: Mechanical or chemical polishing is used to remove the surface oxide layer, making the aluminum plate smooth and enhancing its luster.

- Diamond Texture: A diamond pattern is formed on the surface of the aluminum plate through mold pressing or other processes, enhancing aesthetics and slip resistance.