Perforated corrugated aluminum panels are a type of metal building material that combines corrugated structure and perforation process, widely used in architectural decoration, ventilation, and noise reduction.

Perforated corrugated aluminum panels combine both functionality and aesthetics. They are made from aluminum sheets through two processing techniques: perforation and corrugation rolling.

Perforated corrugated aluminum panels are a design choice to enhance aesthetics in architectural applications. They are produced by forming machines—ordinary flat perforated sheets are processed into corrugated panels through a forming machine. In addition to their beautiful appearance, we also provide corrugated perforated panels with higher strength and better noise control.

The corrugated structure of perforated corrugated aluminum panels significantly improves the stiffness of the sheet (bending strength is more than 30% higher than flat sheets), while the perforation design provides ventilation, lighting, sound absorption, and shading functions.

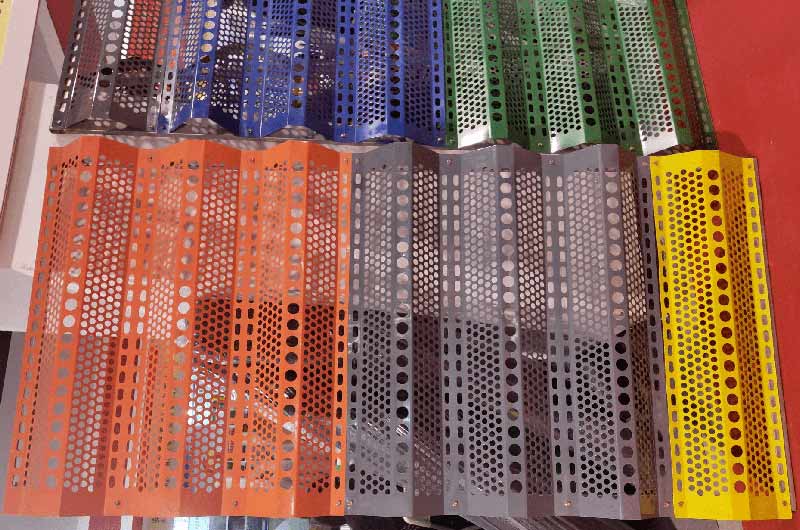

Haomei Aluminum provides you with corrugated perforated panels in various metal profiles, hole patterns, and finishes. We also offer structural design, installation support, customization of open areas, and coil patterns, providing comprehensive support for any interior or exterior construction and renovation project.

Core Features and Advantages of Perforated Corrugated Aluminum Panels

- Lightweight yet strong: Aluminum sheets are inherently lightweight, but when rolled into corrugated shapes, their bending strength is significantly enhanced, reducing the load on building structures. While reducing self-weight, they also optimize load-bearing structures.

- Excellent durability: Aluminum alloy materials themselves have good anti-rust and corrosion resistance. After surface treatments such as powder coating (for both indoor and outdoor use) or fluorocarbon coating (especially suitable for outdoor applications), their weather resistance is further enhanced, maintaining rust-free and corrosion-free performance for over ten to twenty years.

- Outstanding decorative and customizable properties: This is one of their biggest highlights. You can customize the hole shape (such as round, square, or even special patterns), hole size, arrangement (straight row, 45° or 60° staggered rows, etc.), as well as different surface colors and textures (such as RAL color system coating, wood grain finish, etc.).

- Weather resistance: Aluminum alloy base material treated by anodizing or PVDF fluorocarbon coating can withstand extreme temperatures from -50℃ to 80℃, with a service life of over 25 years even in high-salt coastal environments.

- Lightweight design: Panels with thicknesses of 0.8-3.0mm weigh only 6-12kg/㎡, which is just one-third the weight of stainless steel, significantly reducing building loads.

- Acoustic performance: With a perforation rate of 15%-30%, the Noise Reduction Coefficient (NRC) can reach 0.7-0.9, suitable for noise-sensitive areas such as airports and subways.

Multiple Functions

- Ventilation and light transmission: Perforation design (round holes/square holes/slot holes, etc.) can adjust airflow and light transmission rate.

- Noise reduction and shading: Control sound wave reflection and reduce solar radiation impact through hole size and perforation rate.

- Security and weather resistance: Minimum hole diameter of 0.5mm can meet security requirements, while also offering corrosion resistance, fire resistance, and moisture resistance.

Environmentally friendly and recyclable

Aluminum sheets can be 100% recycled and reused, meeting green building standards.

Classification and Specifications of Perforated Corrugated Aluminum Panels

Classification of Perforated Corrugated Aluminum Panels

By Alloy Composition

- Pure aluminum sheets (such as 1060, 1100 series)

- Alloy aluminum sheets (such as 3003, 5052 series)

By Thickness

- Thin sheets (0.15-2.0mm)

- Regular sheets (2.0-6.0mm)

- Medium-thick sheets (6.0-25.0mm)

Hole Types and Panel Shapes

- Hole types: round, square, diamond, slot, etc.

- Panel shapes: flat, wave-shaped, arc-shaped, etc.

Common Thicknesses of Perforated Corrugated Aluminum Panels

The thickness of perforated corrugated aluminum panels directly affects their strength, weight, processability, and cost.

Typical Thickness Range

- Thin sheets: 0.15mm-2.0mm, mainly used for decorative applications and occasions with strict weight requirements.

- Medium sheets: 2.0mm-6.0mm, the most commonly used thickness range, suitable for most architectural decoration and structural applications.

- Thick sheets: 6.0mm-25.0mm, mainly used for special applications requiring high strength.

| Application Scenario | Recommended Thickness Range | Typical Thickness |

| Interior decoration | 0.8mm-2.0mm | 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm |

| Exterior wall decoration | 1.5mm-3.0mm | 1.5mm, 2.0mm, 2.5mm, 3.0mm |

| Roofing | 2.0mm-4.0mm | 2.0mm, 2.5mm, 3.0mm, 4.0mm |

| Structural applications | 3.0mm-6.0mm | 3.0mm, 4.0mm, 5.0mm, 6.0mm |

Thickness Selection Guide

The higher the perforation rate, the lower the strength of the sheet, so thicker panels must be selected. When the perforation rate exceeds 50%, it is recommended to use aluminum sheets with a thickness of no less than 3.0mm to ensure flatness and strength. Deep corrugation designs can allow for thinner sheets without compromising strength, while shallow corrugations or flat designs require relatively thicker sheets to maintain strength.

Common Standard Sizes of Perforated Corrugated Aluminum Panels

Standard Panel Sizes (inches)

- 48" x 96" (4' x 8'): the most common standard size, equivalent to 1220mm x 2440mm

- 24" x 48" (2' x 4'): equivalent to 610mm x 1220mm, suitable for smaller projects

- 48" x 48" (4' x 4'): equivalent to 1220mm x 1220mm, suitable for applications requiring square panels

- Custom Sizes: non-standard sizes customized according to customer requirements, maximum up to 1500mm x 4000mm

Specific Dimensional Parameters of Corrugated Panels

Height of Corrugation

Common corrugation heights: 0.2" (5mm), 0.4" (10mm), 0.6" (15mm), 0.8" (20mm), 1.0" (25mm), 1.4" (35mm), etc.

Pitch of Corrugation

Common corrugation pitches: 2" (50mm), 4" (100mm), 6" (150mm), 8" (200mm), etc.

Effective Width

Common effective widths: 24" (610mm), 30" (760mm), 36" (915mm), 48" (1220mm), etc.

Common Alloy Types of Perforated Corrugated Aluminum Panels

The alloy type of perforated corrugated aluminum panels directly affects their physical properties, processability, and service life.

1000 Series Pure Aluminum

- Contains more than 99% aluminum, with extremely high corrosion resistance, excellent processing performance, and relatively low strength.

- Application scenarios: occasions requiring high corrosion resistance but low strength; decorative applications

3000 Series Aluminum-Manganese Alloy

- The most widely used anti-rust aluminum series, with good corrosion resistance, especially resistance to marine atmospheric corrosion, and good weldability.

- Application scenarios: occasions requiring high plasticity and good weldability; low-load parts working in liquid or gas media

5000 Series Aluminum-Magnesium Alloy

- Has relatively high strength and good corrosion resistance, especially resistance to marine atmospheric corrosion, with good welding performance.

- Application scenarios: occasions requiring higher strength and corrosion resistance; buildings in marine environments

6000 Series Aluminum-Magnesium-Silicon Alloy

Belongs to heat-treatable aluminum alloys, with medium to high strength, good corrosion resistance, and excellent processing performance. Application scenarios: building structures requiring higher strength; occasions requiring heat treatment strengthening

Alloy Selection Guide

3003 aluminum alloy is the most commonly used material for perforated corrugated aluminum panels, due to its good processing performance, moderate strength, and excellent corrosion resistance. For projects requiring higher strength and corrosion resistance, 5052 or 6061 aluminum alloy can be considered.

Perforated Corrugated Aluminum Panels Surface Treatment Processes

The surface treatment of perforated corrugated aluminum panels not only affects their appearance but also directly relates to their service life, corrosion resistance, and maintenance requirements.

Anodizing

- Forms an oxide film on the aluminum surface through electrochemical methods, providing high hardness and wear resistance, while retaining the metallic texture of aluminum and presenting a natural, rustic color.

- Application scenarios: places requiring fire resistance and insulation; architectural projects pursuing simple, natural styles

Fluorocarbon Coating (PVDF)

- Uses fluorocarbon resin as the main film-forming material, featuring excellent weather resistance, corrosion resistance, and self-cleaning properties. It does not easily fade or chalk even in harsh outdoor environments for long periods.

- Application scenarios: exterior wall decoration of high-rise buildings; coastal buildings; buildings in industrially polluted areas

Brushed Finish

- Creates fine linear textures on the aluminum surface, enhancing the surface’s three-dimensional and layered effect, effectively covering minor flaws, reducing glare, and producing a softer, more comfortable visual effect.

- Application scenarios: indoor spaces with high decorative requirements; high-end clubs; villa wall decorations

Lamination Treatment

- Applies films with specific colors, patterns, or textures onto the perforated aluminum sheet surface through hot pressing or adhesive methods, simulating natural materials such as wood grain, stone grain, or fabric grain.

- Application scenarios: projects requiring diverse decorative effects with limited budgets; fast-fashion store renovations; temporary exhibition space arrangements

Powder Coating

- Uses static electricity to evenly adsorb dry thermosetting powder coatings onto the aluminum surface, providing a variety of color options, with high color saturation. The coating has good wear resistance and weather resistance.

- Application scenarios: interior decoration, such as ceilings or wall decorations in shopping malls and hotel lobbies

Electroplating

- Deposits a metallic coating on the aluminum surface through electrolysis. Nickel plating gives the surface a bright luster, while chrome plating provides a mirror-like finish, enhancing decorative grade.

- Application scenarios: high-end commercial spaces; luxury hotels; lobby column decorations in high-end office buildings

| Process Type | Typical Thickness | Weather Resistance Lifespan | Suitable Scenarios |

| Powder Coating | 60-80μm | 10-15 years | Indoor decoration, general outdoor use |

| Fluorocarbon Coating (PVDF) | 40-60μm | 20-30 years | Coastal, high-pollution areas |

| Anodizing | 8-25μm | 15-20 years | High-end projects requiring metallic texture |

| Brushed + Lamination | 30-50μm | 8-10 years | Temporary exhibitions, quick-change scenarios |

Note: PVDF coating is AAMA 2605 certified, passes salt spray tests exceeding 3000 hours, suitable for long-term outdoor exposure.

Perforated Corrugated Aluminum Panels Applications

- Building facades and sunshade systems: a very common application. It creates a unique appearance for buildings while providing shading and energy-saving functions.

- Interior decoration: such as ceilings, wall panels, partitions, and screens, creating modern and stylish indoor space effects.

- Other specific uses: such as louvers, ventilation grilles, equipment enclosures, product shelves, and acoustic barriers.

- Functional facilities: shading for parking lots, covering pipeline systems, etc.

Perforated Corrugated Aluminum Panels Purchasing Considerations

| Consideration Dimension | Description & Options | Practical Advice |

| Application Environment | Indoor: powder coating and other surface treatments can be selected. | |

| Outdoor: stronger weather-resistant surface treatments such as PVDF coating are required, ensuring the panel and coating thickness meet outdoor use standards. | ||

| Aperture & Open Area Ratio | Aperture size (e.g. 5mm, 8mm, 10mm, 15mm) and open area ratio (e.g. 50%) directly affect appearance, light transmission, ventilation, and shading. | Clarify functional needs: how much light transmission? how much ventilation? what shading effect? Select based on design requirements. |

| Material & Thickness | Common materials include 1060, 3003, 5005 aluminum alloys. Typical thicknesses are 1.0mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm or thicker. | For outdoor or high-strength applications, choose thicker panels; for interior decoration, thinner panels may be used. |

| Corrugation Specifications | The corrugation peak height (e.g. 70mm), pitch, etc. affect the three-dimensional effect and strength. | If specific visual or structural requirements are needed, confirm details with the supplier. |

| Surface Treatment | Powder coating (various colors, suitable for indoor/outdoor), PVDF coating (excellent outdoor durability), anodizing, wood grain imitation, etc. | For outdoor use, prioritize PVDF coating; for indoor use, select colors and textures based on design style. |

| Customization | Panel size, perforation patterns, surface colors, etc. are usually customizable. | Provide detailed design drawings or clear requirements, and fully communicate with the supplier regarding feasibility, production cycle, and cost impact. |

Performance Comparison Between Perforated Corrugated Aluminum Panels and Alternative Materials

| Material Type | Density (kg/m³) | Weather Resistance Lifespan | Thermal Conductivity (W/(m·K)) | Fire Rating |

| Perforated Corrugated Aluminum Panels | 2700 | 15-30 years | 237 | Class A2 |

| Perforated Stainless Steel Panels | 7900 | 20-50 years | 16.3 | Class A1 |

| PVC Perforated Panels | 1400 | 5-8 years | 0.16 | Class B1 |

Note: Aluminum panels have significant advantages in terms of lightweight properties and cost performance; stainless steel is suitable for highly corrosive environments; PVC is only recommended for temporary projects.

With its flexible design freedom, excellent performance, and sustainable characteristics, perforated corrugated aluminum panels are becoming one of the preferred materials in modern architecture and industrial design.