Hydrophilic aluminum foil is a type of functional material that has undergone special surface treatment to form a hydrophilic layer on the surface of the aluminum foil. Its notable feature is the ability to allow water to quickly spread into a thin film across the surface instead of forming water droplets, thereby improving heat exchange efficiency and corrosion resistance.

Hydrophilic aluminum foil is produced through roller coating or chemical conversion processes, in which a hydrophilic coating containing polar groups such as hydroxyl (-OH) is applied to the surface of the aluminum foil (e.g., acrylic resin or silane coupling agent). This reduces the contact angle between water and the aluminum foil surface to less than 25°. As a result, condensation water spreads rapidly into a uniform water film on the foil surface, preventing droplet accumulation and blockage of heat exchange channels, thus improving heat exchange efficiency by 5%–15%.

How Hydrophilic Coating Improves Heat Exchange Efficiency

During use, hydrophilic aluminum foil enables condensate water to quickly spread into a uniform water film on the surface:

- Prevents water droplet accumulation and blockage of airflow channels.

- Keeps the heat exchange surface clean and unobstructed.

- Improves airflow efficiency and heat transfer performance.

- Untreated (hydrophobic) surface: Ordinary aluminum foil is hydrophobic. When an air conditioner operates in cooling mode, the surface temperature of the evaporator fins becomes very low, causing water vapor in the air to condense on the surface. Because of the hydrophobic nature, the water gathers into large droplets.

- Hydrophilic surface: The surface coating of hydrophilic aluminum foil contains hydrophilic groups that reduce the surface tension of water. When condensation occurs, the water quickly spreads over the fin surface to form a uniform thin film.

Benefits of hydrophilic aluminum foil:

- Improved heat exchange efficiency: Water droplets are poor conductors of heat. Large droplets forming between fins create “water bridges, ” obstructing airflow and reducing heat exchange efficiency. In contrast, a thin water film creates much less resistance to airflow and can be quickly carried away, maintaining high heat exchange efficiency.

- Reduced air resistance and noise: A water film is smoother than water droplets, resulting in less resistance to airflow through the fins. This not only reduces fan energy consumption but also lowers noise caused by air movement and droplet vibration.

- Corrosion and mold resistance: Hydrophilic coatings often contain anti-corrosive components (such as chromates or chromium-free formulations) that protect the aluminum substrate. Meanwhile, the rapid runoff of the water film reduces the duration of surface wetness, suppressing mold and bacterial growth and improving indoor air quality.

- Prevention of “water splash” phenomenon: When condensate water is blown out by the fan during operation — a situation known as “water splash” or “water carryover” — it can affect user experience. Hydrophilic aluminum foil allows water to drain away quickly, effectively preventing this problem.

Typical Specifications and Materials of Hydrophilic Aluminum Foil

- Alloy used: 1100, 1200, 1030, 3003, 3102, 8011, 8006, 8021, etc.

- Temper: O, H22, H24, H26, etc.

- Thickness: from 0.08 mm to 0.15 mm.

- Width: 50 mm to 1250 mm.

- Coating thickness: 1.0 to 3.0 μm.

- Hydrophilic angle (the smaller the contact angle, the better): initial contact angle ≤5°, aged ≤25°.

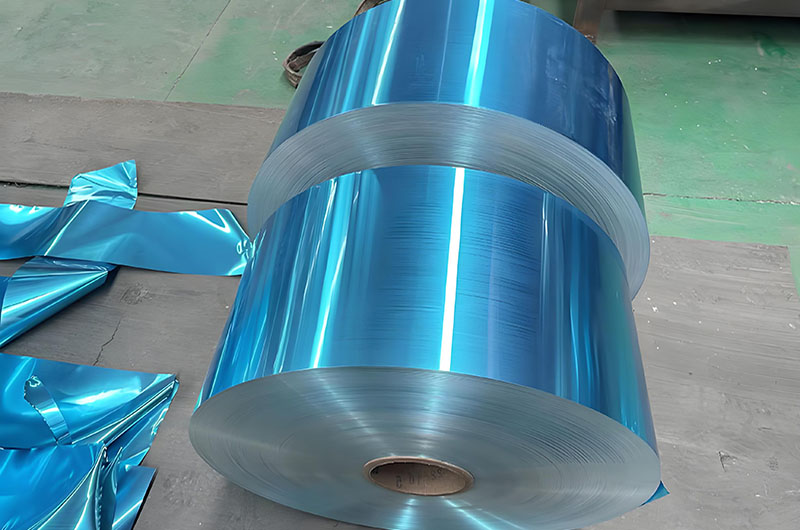

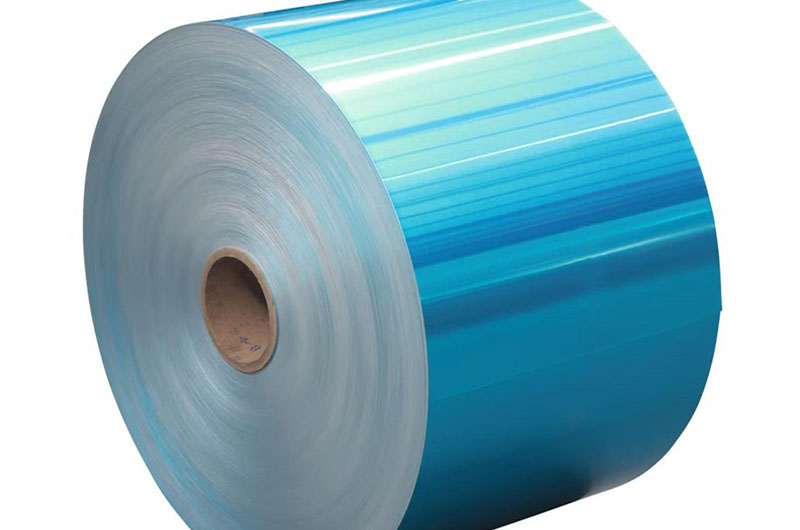

- Color/coating: natural silver/gray, blue, gold, etc. The coating can add color or enhance aesthetics.

Characteristics and Advantages of Hydrophilic Aluminum Foil

Improved Heat Exchange Efficiency:

Condensate water does not gather into droplets, reducing airflow resistance and improving heat exchange efficiency by 5%–15%.

Better Airflow Distribution:

The formation of a continuous water film allows smoother airflow, reducing energy consumption and noise.

Reduced “Water Bridge” Phenomenon:

Prevents condensate water from forming bridges between fins, avoiding blockage of air channels.

Enhanced Corrosion Resistance:

The hydrophilic coating provides protective properties, extending the service life of the aluminum foil and heat exchanger.

- Higher heat exchange and thermal performance: Since condensate water spreads into a film rather than forming discrete droplets, airflow through the fins is less obstructed and the heat transfer area is more effectively utilized.

- Better corrosion resistance and durability: The hydrophilic coating usually also provides corrosion resistance, extending service life and improving performance in HVAC or refrigeration environments.

- Anti-mold and oxidation resistance: Because moisture does not remain as droplets, the likelihood of mold, dirt, or oxide buildup is greatly reduced.

- Wetting control: By designing the surface to encourage water spreading rather than droplet formation, “water bridges” between fins — which increase airflow resistance — can be avoided.

Popular Haomei Aluminum Hydrophilic Foil

8011 H16 Hydrophilic Aluminum Foil

8011 H16 hydrophilic aluminum foil is primarily used in refrigerant pipelines and the housings of outdoor units in air conditioning systems. This aluminum foil undergoes special treatment to impart excellent hydrophilic properties, effectively improving heat exchange efficiency.

Features:

- Superior Hydrophilic Performance: In air conditioning systems, 8011 H16 hydrophilic aluminum foil allows condensate to spread quickly, avoiding droplet accumulation and thereby enhancing the cooling effect of the system.

- Corrosion Resistance: With specialized hydrophilic treatment, this aluminum foil exhibits good corrosion resistance, maintaining stable performance in harsh environments.

- Durability: This foil maintains its performance even under high temperatures and humidity, making it suitable for long-term use in various air conditioning equipment.

1100/1200 O H11 Hydrophilic Aluminum Foil

1100/1200 O H11 hydrophilic aluminum foil is widely used in air conditioners, heat exchangers, evaporators, and other applications. Its excellent workability and corrosion resistance make it an ideal material for these devices.

Features:

- Excellent Workability: This aluminum foil is easy to process and shape, suitable for various manufacturing processes, and can meet the demands for complex shapes and sizes.

- Corrosion Resistance: The hydrophilic treatment provides superior corrosion resistance, effectively preventing corrosion caused by environmental factors.

- Stable Performance: It maintains stable performance over long-term use, ensuring the reliability and efficiency of the equipment.

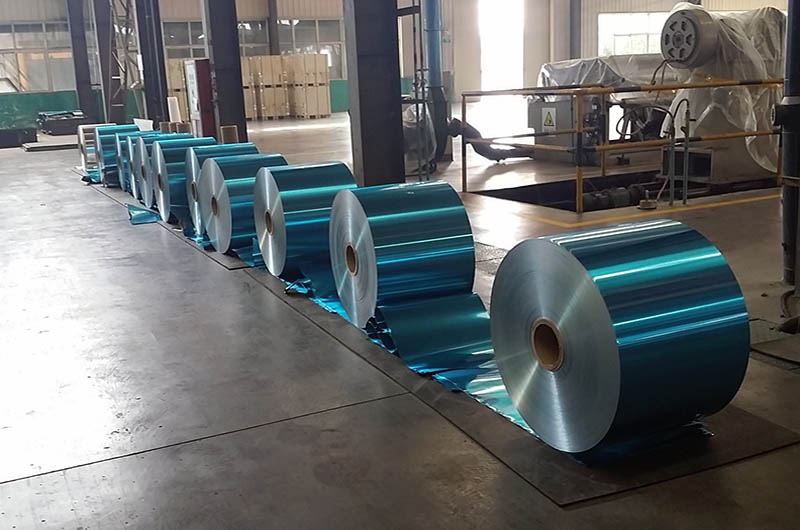

Blue Hydrophilic Aluminum Foil

Blue hydrophilic aluminum foil features a special hydrophilic coating that provides excellent corrosion resistance, effectively preventing corrosion of air conditioning fins and heat exchangers during use.

Gold Hydrophilic Aluminum Foil

Gold hydrophilic aluminum foil is commonly used in high-end air conditioning equipment. Its gold coating not only adds aesthetic appeal but also offers outstanding corrosion resistance, significantly extending the lifespan of the equipment.

Gold hydrophilic aluminum foil maintains its appearance and performance over long-term use, making it suitable for applications requiring high durability.

Performance parameters of hydrophilic foil

| Coating thickness | 1.0~3.0μm (The average thickness of single side) |

| Hydrophilia | The initial hydrophilic angle≤5; Continuous hydrophilic angle≤25 |

| Adhesive force | Cupping Test (pressure deep 5mm): no flaking. Grid experiment (100/100): no delaminating. |

| Corrosion resistance | Salt fog test (72 Hours) R.N≥9.5 |

| Alkali resistance | With 20 degree centigrade, soak in the 20%NaOH with 3 Minutes, the sample coating layer totally no frothing. |

| Solvent resistance | Weight loss of Sample≤1% |

| Heat resistance | Under 200℃, keep for 5 minute, properties and the color remains the same; Under 300℃, keep for 5 minutes, coating layer just become light yellow. |

| Oil resistivity | In the volatile oil soaked for 24 hours, coating layer has no frothing |

Mechanical Properties of Aluminum Hydrophilic Foil

| Alloy | Temper | Indoor Mechanical Property | ||

| Tensile Strength | Elongation (%) | Cupping Test Value | ||

| 8011 | O | 80~100 | ≥20 | ≥6.0 |

| H22 | 100~135 | ≥16 | ≥5.5 | |

| H24 | 115~145 | ≥12 | ≥5.0 | |

| H26 | 125~160 | ≥8 | ≥4.0 | |

| H18 | ≥160 | ≥1 | - | |

Tolerances of Aluminum Hydrophilic Foi

| Thickness and thickness Tolerance(mm) | Width and Width Tolerance(mm) | ID(mm) | Max OD (mm) | ID Material |

| 0.095~0.50 (±0.005) | 50~1250 (±0.5) | ¢75, ¢150, ¢200 ¢300 ¢400 ¢500 | ¢≤1400 | Paper core, aluminium core |

Hydrophilic Foil Coating Performance

| Project Indicator | Technology Indicator | |

| Coating thickness | 1.0~3.0UM(The Average Thickness of Single Side) | |

| Hydrophilia | The Initial Hydrophilic Angle | The Initial Hydrophilic Angle ≤5 |

| Continuous Hydrophilic Angle | Continuous Hydrophilic Angle≤25 | |

| Adhesive Force | Cupping Test(pressure deep 5mm):No Flaking: Grid experiment(100/100):No Delaminating | |

| Corrosion Resistance | Salt fog test(72 Hours)R.N≥9.5 | |

| Alkali Resistance | With 20 degree centigrade , soak in the 20%NaOH with 3 Minutes, the sample coating layer totally no frothing | |

| Solvent Resistance | Weight loss of Sample≤1% | |

| Heat Resistance | Under 200 degrees Celsius, Keep for 5 minutes, Properties and the color remains the same;Under 300 degrees Celsius, Keep for 5 minutes, Coating layer just become light yellow. | |

| Oil Resistivity | In the volatile oil soaked for 24 hours, Coating layer has no frothing | |

| Coating Smell | No off-smell | |

| To the mold wear | Same as the ordinary aluminium foil | |

How to Evaluate the Performance of Hydrophilic Aluminum Foil

The main indicators used to evaluate the quality of hydrophilic aluminum foil include:

- Hydrophilicity (contact angle): The smaller the contact angle between a water droplet and the coating surface, the better the hydrophilicity. High-quality products usually have an initial contact angle of less than 10°.

- Water resistance/durability: Whether the coating can maintain its hydrophilic properties after long-term exposure or under high-temperature and high-humidity conditions. This is a key measure of its service life.

- Corrosion resistance: The coating’s ability to protect the aluminum substrate from corrosion (e.g., salt spray tests).

- Adhesion: The strength of the bond between the coating and the aluminum foil substrate.

- Antibacterial property: Some high-end products incorporate antibacterial agents into the coating to provide antimicrobial functionality.

Comparison Between Hydrophilic Aluminum Foil, Ordinary Aluminum Foil, and “Hydrophobic Aluminum Foil”

| Property | Ordinary Aluminum Foil | Hydrophilic Aluminum Foil | Hydrophobic Aluminum Foil |

| Surface characteristics | Hydrophobic | Hydrophilic | Superhydrophobic |

| Condensate form | Forms large water droplets | Spreads into a thin water film | Forms easily rolling water droplets |

| Main advantages | Low cost | Improved energy efficiency, reduced noise, anti-corrosion | Self-cleaning, anti-icing |

| Main applications | Packaging, etc. | Air conditioner heat exchangers | Heat exchangers in specific environments (e.g., low-temperature anti-frost) |

Comparison between Aluminum Hydrophilic Foil and Hydrophobic Foil

Hydrophobic foil repels water (e.g., for waterproofing), whereas hydrophilic foil controls moisture to improve thermal or hygienic performance.

| Comparison Item | Aluminum Hydrophilic Foil | Hydrophobic Aluminum Foil |

| Water Contact Angle | Low contact angle (<30°), water spreads evenly on the surface to form a uniform water film. | High contact angle, water droplets maintain a spherical shape and roll off quickly, not easily adhering. |

| Moisture Management | Promotes uniform flow of condensed water along the surface, reducing water droplet accumulation and improving heat exchange efficiency. | Repels water droplets, allowing them to be quickly expelled, preventing moisture infiltration and accumulation. |

| Application Areas | Widely used in air conditioning heat exchangers, condensers, evaporators, and other heat exchange equipment to enhance energy efficiency and improve heat exchange performance. | Mainly applied in outdoor equipment, electronic component protection, waterproof coatings, and environments requiring moisture and waterproofing. |

| Thermal Conductivity | Due to the uniform coverage of the water film, thermal conductivity is enhanced, improving the performance of refrigeration and heating systems. | Hydrophobic surfaces reduce water coverage, which may affect heat exchange performance but excels in waterproofing. |

| Corrosion Resistance | The hydrophilic coating typically includes corrosion-resistant components, reducing oxidation and corrosion, thus improving material durability. | Hydrophobic coatings can also enhance corrosion resistance, especially in humid or salt-spray environments, reducing material degradation. |

| Antibacterial Properties | Some hydrophilic coatings contain silver ions or other antimicrobial agents to inhibit mold and bacteria growth, improving air quality. | Hydrophobic surfaces reduce water retention, indirectly decreasing the likelihood of bacterial and mold growth, but do not have direct antibacterial properties. |

| Suitable Environments | Suitable for air conditioning systems, air purification devices, medical environments, etc., where enhanced heat exchange and hygienic performance are required. | Suitable for building waterproof layers, roof coatings, outdoor electronic equipment protection, and electronic device moisture-proofing in environments requiring waterproofing. |

Comparison Between Hydrophilic Aluminum Foil and Plain Aluminum Foil

| Characteristic | Hydrophilic Aluminum Foil | Plain Aluminum Foil |

| Surface Treatment | Hydrophilic + Anti-corrosion Coating | No Coating |

| Heat Exchange Efficiency | Improved by 5%-15% | Basic Level |

| Anti-Clogging | Prevents Water Bridge Blockage | Prone to Water Accumulation and Ventilation Obstruction |

| Lifespan | Longer (Anti-Aging Treatment) | Easily Oxidized and Degraded |

Application Scenarios of Hydrophilic Aluminum Foil

- Residential/Commercial Air Conditioning: Used for heat exchanger fins, improves cooling efficiency by 5%, reduces noise, and prevents frosting.

- Industrial Cooling: Suitable for condensers in high humidity environments.

- Automotive: Enhances heat dissipation performance in automotive air conditioning and electric vehicle battery thermal management.

- Packaging: Due to its moisture and oxygen resistance, it can be used as a barrier material for food/pharmaceutical packaging.

| Alloy | Temper | Key Applications |

| 8011 | O/H22/H24 | AC fins, refrigerant pipes |

| 1100 | O/H11 | Heat exchangers, evaporators |

| 3102 | H24 | High-humidity environments |

Hydrophilic aluminum foil plays a crucial role in modern refrigeration technology, particularly in the heat exchange fins of various air conditioning systems. Its applications span across home air conditioners, refrigerators, and automotive air conditioners.

| Application Area | Description |

| Air Conditioning Equipment | Aluminum Hydrophilic Foil, as the core material of heat exchange fins, is widely used in home air conditioners, automobile air conditioners, refrigerators, and other refrigeration systems. Its low contact angle characteristic allows for the uniform distribution of condensate water, reducing water droplet adhesion and thus improving heat exchange efficiency. Furthermore, the foil’s anti-corrosion and anti-mold properties extend the lifespan of the equipment, while its noise reduction effect helps reduce operating noise and improve user experience. |

| Air Conditioning Units | Aluminum Hydrophilic Foil plays a key role in air conditioning units, whether for home or automobile use. Its excellent hydrophilicity promotes the rapid expulsion of condensate water, preventing water accumulation that could obstruct airflow. This characteristic not only improves cooling efficiency but also reduces the load on compressors, lowering overall energy consumption and making air conditioning systems more energy-efficient and environmentally friendly. |

| Refrigeration Equipment | Aluminum Hydrophilic Foil is widely used in evaporators and condenser coils of refrigeration equipment. With its excellent ability to form a water film, it effectively reduces frost accumulation and prevents ice layers from affecting heat exchange efficiency. This feature ensures that the equipment maintains consistent performance even in low-temperature environments, thereby improving refrigeration effects in food storage, pharmaceutical storage, and other fields. |

| Professional Industrial Uses | Aluminum Hydrophilic Foil is also of significant value in professional industrial applications. In addition to its use in cooling systems, it is also applied in environments where humidity management is critical, such as in the packaging of food, pharmaceuticals, and electronic components. Its uniform moisture distribution ability helps reduce humidity fluctuations, preventing product spoilage and ensuring quality stability during storage and transportation. |

| HVAC and Heat Exchangers | Aluminum Hydrophilic Foil plays an important role in HVAC systems and heat exchangers. Its unique ability to prevent water droplet formation helps reduce water accumulation on heat exchange surfaces, preventing heat exchange efficiency degradation caused by water film insulation effects. By improving the evaporative cooling process, it enhances the overall performance of air conditioning systems, ensuring that equipment operates efficiently even in high humidity environments. |

| Energy Systems | Aluminum Hydrophilic Foil can be used in energy systems to improve the efficiency of dehumidifiers and fuel cell components. Its excellent hydrophilicity helps efficiently expel moisture, reducing the impact of humidity on equipment performance and enhancing the operational stability of energy equipment. In fuel cell applications, it can optimize water management and improve the efficiency of electrochemical reactions, contributing to the development of new energy technologies. |

Air Conditioning Heat Exchange Fins

- Improved Cooling and Heating Efficiency: Hydrophilic aluminum foil, with its special hydrophilic coating, allows condensation to spread rapidly on the fins' surface, avoiding water droplet accumulation. This increases the heat exchange area and speeds up cooling and heating, thereby enhancing the overall efficiency of the air conditioning system.

- Enhanced Durability: Its excellent anti-corrosion and anti-mold properties effectively prevent damage from moisture and corrosion in the environment, thus extending the lifespan of the air conditioning equipment.

Refrigerator Condenser and Evaporator Heat Exchange Fins

- Increased Cooling Efficiency: The high hydrophilicity of the aluminum foil ensures that condensation spreads quickly, preventing the reduction in heat exchange efficiency caused by water droplet accumulation, thus enhancing the cooling effect of the refrigerator.

- Frost Prevention: Since condensation does not form into ice beads, hydrophilic aluminum foil effectively prevents frost formation on condensers and evaporators, maintaining stable operation of the equipment.

Automotive Air Conditioning

In automotive air conditioning systems, hydrophilic aluminum foil is primarily used in the heat exchangers of vehicle air conditioning units.

- Enhanced Cooling Effect: The rapid spreading of condensation with hydrophilic aluminum foil can improve the cooling efficiency of the vehicle's air conditioning system, making the interior environment more comfortable.

- Increased Durability: Its anti-corrosion properties ensure that automotive air conditioners maintain stable performance in various driving conditions, such as humid or salt-laden environments.

Hydrophilic aluminum foil is a high-performance material that, due to its superior hydrophilicity and anti-corrosion characteristics, has become an indispensable component in modern air conditioning and refrigeration equipment. Its application in home air conditioners, refrigerators, and automotive air conditioners not only enhances the heat exchange efficiency but also improves durability and reliability, providing users with more efficient and long-lasting cooling solutions.

Production Process of Hydrophilic Aluminum Foil

Rolling Process Introduction

The production process involves advanced surface treatment beyond standard aluminum foil:

- Raw Material Preparation: High-purity aluminum alloys (such as 8011, 1100, 3102) are melted and rolled to precise thickness (0.01–0.3 mm).

- Surface Treatment: The aluminum foil undergoes degreasing, cleaning, and a two-stage coating treatment.

- Hydrophilic Coating: Applied through chemical processes to attract water molecules.

- Anti-Corrosion Layer: Enhances durability in humid environments.

- Curing: Treated at 200°C–300°C to stabilize the coating and prevent yellowing.

Key Difference from Standard Aluminum Foil: Additional coating steps (such as dual-coating and dual-baking) are critical to performance.

When and Why to Choose Hydrophilic Aluminum Foil

If your design involves fin surfaces where condensation or moisture may occur and you want to minimize droplet formation and related issues (such as decreased heat transfer performance, increased pressure or airflow resistance, and higher risks of corrosion or scaling), choose hydrophilic aluminum foil.

If you are using ordinary aluminum foil and moisture behavior is not a critical concern, then the additional cost and coating may not be justified.

Related Questions About Aluminum Hydrophilic Foil

Why is aluminum foil hydrophilic?

Aluminum foil itself does not have inherent hydrophilicity, but it can be treated to acquire this property.

- Surface Treatment: Aluminum foil is subjected to degreasing, cleaning, and acid etching to remove surface oil and oxidation, making it more receptive to subsequent coatings.

- Application of Hydrophilic Coating: A hydrophilic coating (usually organic or inorganic) is applied to the aluminum foil surface, giving it hydrophilic properties. This coating attracts water and encourages rapid spreading of moisture rather than forming droplets.

What is hydrophilic aluminum?

Hydrophilic aluminum refers to aluminum materials that have been specially treated with a hydrophilic coating.

Characteristics of Hydrophilic Aluminum:

- Hydrophilic Coating: The surface is coated with a layer that forms hydrogen bonds with water molecules, allowing water to easily contact and spread across the aluminum surface.

- Corrosion Resistance: Hydrophilic aluminum typically has excellent anti-corrosion properties, protecting against corrosion in moist environments.

- Improved Heat Exchange: When used in heat exchangers, hydrophilic aluminum can enhance heat exchange efficiency because condensation does not pool into droplets, increasing the heat exchange area.

Does aluminum foil react with water?

Under normal conditions, aluminum foil does not undergo significant chemical reactions with water. However, under certain specific conditions, the reaction can occur as follows:

- Under Normal Conditions: At room temperature and pressure, aluminum foil does not directly react with water. The surface of aluminum typically forms a thin layer of aluminum oxide, which protects it from further corrosion by water or oxygen in the air.

- In Strongly Alkaline or Acidic Environments: In strongly alkaline (e.g., sodium hydroxide solution) or strongly acidic environments, aluminum foil may react with water. For example, in an alkaline environment, aluminum reacts with water to produce hydrogen gas and aluminum hydroxide.

Hydrophilic-treated aluminum foil does not directly react with water but utilizes its improved surface characteristics to enhance heat exchange efficiency and corrosion resistance.