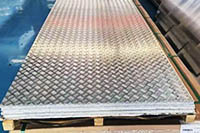

Aluminum diamond plate is a material commonly used for both interior and exterior decoration and protection of cargo trailers. Its surface typically features a unique diamond-patterned texture, which is not only aesthetically pleasing but also provides various practical functions.

Aluminum diamond plate (also known as checker plate) has become a popular choice for cargo trailers due to its slip resistance, lightweight durability, corrosion resistance, and modern appearance.

Aluminum Diamond Plate for Cargo Trailer Key Advantages

- Durability and Strength: Aluminum diamond plate is known for its sturdy and durable characteristics, making it ideal for high-traffic areas such as trailer flooring. It can withstand heavy loads and impacts, ensuring long-term performance.

- Slip Resistance: The raised diamond pattern provides excellent traction, reducing the risk of slips and falls. This is especially important for trailers transporting machinery, equipment, or cargo that may shift during transit.

- Corrosion and Weather Resistance: Aluminum naturally offers rust and corrosion resistance, making it suitable for outdoor use and environments exposed to moisture, chemicals, or harsh weather.

- Easy Maintenance: The aluminum surface is easy to clean with basic tools, and maintenance costs are much lower compared to wood or other materials.

- Aesthetics: The diamond plate adds a stylish and professional look to the trailer, enhancing its overall appearance.

- Lightweight: Compared to steel, aluminum is lighter, helping to improve fuel efficiency without sacrificing strength.

Aluminum Diamond Plate for Cargo Trailer: Alloy, Size & Thickness Selection

Common Alloys for Aluminum Diamond Plate in Cargo Trailers

- 3003 Aluminum: Manganese-containing alloy with good corrosion resistance and weldability. Suitable for general-purpose trailers, including flooring and fenders.

- 5052 Aluminum: Magnesium-containing alloy with higher tensile strength (230–280 MPa) and better stress corrosion resistance. Ideal for ramps or structural components in heavy-duty applications.

- 6061 Aluminum: Heat-treated alloy with higher strength and broader applications, commonly used in high-stress areas such as trailer frames.

Thickness Options for Aluminum Diamond Plate in Cargo Trailers

- 1/8 inch (3.2 mm): Most commonly used for trailer flooring and sidewalls, balancing rigidity and weight.

- 3/16 inch (4.8 mm): Recommended for high-traffic areas or heavy-duty loads.

- Thinner options (e.g., 1.5–2 mm) are used for decorative panels or non-structural components.

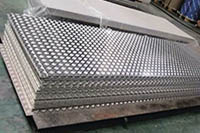

Size Options for Aluminum Diamond Plate in Cargo Trailers

- 1' x 1' (12 x 12) aluminum diamond checker plate

- 1' x 2' (12 x 24) aluminum diamond checker plate

- 1' x 4' (12 x 48) aluminum diamond checker plate

- 1' x 10' (12 x 120) aluminum diamond checker plate

- 1.5' x 10' (18 x 120) aluminum diamond checker plate

- 2' x 2' (24 x 24) aluminum diamond checker plate

- 2' x 4' (24 x 48) aluminum diamond checker plate

- 2' x 5' (24 x 60) aluminum diamond checker plate

- 2' x 6' (24 x 72) aluminum diamond checker plate

- 2' x 8' (24 x 96) aluminum diamond checker plate

- 2' x 10' (24 x 120) aluminum diamond checker plate

- 3' x 3' (36 x 36) aluminum diamond checker plate

- 3' x 4' (36 x 48) aluminum diamond checker plate

- 3' x 10' (36 x 120) aluminum diamond checker plate

- 4' x 4' (48 x 48) aluminum diamond checker plate

- 4' x 8' (48 x 96) aluminum diamond checker plate

- 4' x 10' (48 x 120) aluminum diamond checker plate

- 5' x 8' (60 x 96) aluminum diamond checker plate

Recommended Thickness for Aluminum Diamond Plate Trailer Flooring

| Support Structure | Recommended Thickness | Ideal For |

| Plywood base (e.g., 3/4") | 0.045" or 0.063" (1/16") | Light to medium loads; provides adequate protection with solid support. |

| Metal beams or weak support | 0.125" (1/8") or thicker | Heavy loads (e.g., machinery, quads); requires more durability. |

| No additional support | 0.188" (3/16") or 0.25" (1/4") | Extreme loads; standalone use without plywood base. |

Aluminum diamond plate is a versatile and cost-effective upgrade solution for cargo trailers, offering unparalleled durability, corrosion resistance, and safety. By selecting the appropriate alloy, thickness, and installation method, you can enhance the trailer’s performance while minimizing maintenance.

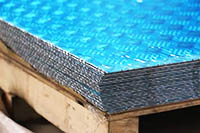

Diamond Tread Plate Color Offerings

Options include raw aluminum or anodized aluminum plates, the latter of which offers a wider range of color choices and enhanced wear resistance.

-

Red aluminum diamond tread plate

-

Grey aluminum diamond tread plate

Applications of Aluminum Diamond Plate in Cargo Trailers

-

Aluminum diamond plate is commonly used as flooring material for cargo trailers. Its unique diamond pattern design not only enhances slip resistance but also provides good load-bearing capacity, ensuring stability and safety when transporting heavy loads. This lightweight and corrosion-resistant material effectively repels liquids and chemicals, extending its lifespan.

-

Aluminum Diamond Sheet Trailer Skin

The aluminum diamond plate trailer skin is an important component that covers the exterior of the trailer. The aluminum exterior provides good impact resistance, effectively protecting the interior of the trailer from external shocks and wear. The aluminum skin is easy to clean and maintain, reducing long-term maintenance burdens.

-

Aluminum Diamond Plate Trailer Fender

Aluminum diamond plate trailer fenders are specially designed protective components for trailers, primarily used to block dirt, stones, and water splashes from the road, preventing these materials from splattering onto other vehicles or pedestrians.

-

Aluminum Diamond Sheet Side and Rear Walls

In the side and rear walls of cargo trailers, aluminum diamond plate plays a significant protective role. It effectively prevents scratches, impacts, and other potential damages, ensuring the vehicle maintains good appearance and structural integrity. Additionally, the lightweight nature of aluminum helps reduce the overall weight of the vehicle, improving fuel efficiency.

-

Aluminum Diamond Plate Tool Boxes and Lockers

Aluminum diamond plate is widely used for making toolboxes and storage lockers in cargo trailers. Its sturdy structure provides extra protection for tools and equipment against external environmental influences. Moreover, the durability of aluminum ensures that these storage spaces remain in good condition under various weather conditions, facilitating the transportation and storage of various items.