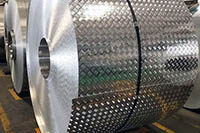

What is an aluminium tread plate?

Aluminum tread plate (also known as aluminum diamond plate, checker plate, or embossed aluminum sheet) is an aluminum product in which various patterned designs are formed on the surface of an aluminum sheet through special processes. It uses pure aluminum or aluminum alloy as the base material, and through rolling processing, specific patterns are formed on the surface, giving it both decorative and functional properties.

Manufacturing Process

- Rolling Process: During the rolling of aluminum sheets, special rollers are used to emboss patterns on the surface. This method offers high production efficiency and is suitable for large-scale manufacturing.

- Stamping Process: Used for creating special shapes or patterns with greater depth, capable of forming more three-dimensional designs. However, the production speed is relatively slower and the cost is higher.

What grade of aluminium is a tread plate?

Common Alloy Grades of Tread Aluminum Sheet Plate

1xxx Series Pure Aluminum (e.g., 1050, 1060, 1100)

- Purity up to 99.5% or higher, featuring excellent electrical conductivity, thermal conductivity, and corrosion resistance.

- Good formability, weldability, and corrosion resistance, but relatively low strength.

- Applications: Mainly used in decorative fields and general protective purposes where corrosion resistance is required.

3xxx Series Aluminum-Manganese Alloys (e.g., 3003, 3004)

- Based on aluminum with about 1.2% manganese element added, providing good corrosion resistance and workability.

- Strength is about 20% higher than pure aluminum, offering certain anti-rust performance.

- Applications: Commonly used in architectural decoration, vehicle flooring, cold storage, and other situations requiring rust resistance.

5xxx Series Aluminum-Magnesium Alloys (e.g., 5052, 5083, 5086)

- With about 2.5% magnesium content, this is one of the most widely used anti-rust aluminum alloys.

- Excellent corrosion resistance, weldability, and medium strength. Hardness is about 60-80% higher than 1xxx series.

- Applications: Especially suitable for humid environments and marine climates, such as ship decks, refrigerated truck flooring, etc.

6xxx Series Aluminum-Magnesium-Silicon Alloys (e.g., 6061, 6063)

- Alloyed with magnesium and silicon, these are heat-treatable alloys.

- Featuring high strength, good corrosion resistance, and weldability. Strength is further enhanced after T6 heat treatment.

- Applications: Suitable for situations requiring high strength and durability, such as truck pedals, mechanical platforms, etc.

Haomei Tread Aluminum Sheet Plate Available Alloy Grades

3003 Tread Aluminum Sheet Plate

3003 tread aluminum plate uses manganese as the main alloying element, featuring good corrosion resistance and formability. It is commonly used in chemical storage tanks, pressure vessels, pipelines, and various decorative parts. Especially in the 3003-H22 condition, it provides certain strength and good corrosion resistance, making it very suitable for lightweight applications that also require appearance quality.

4017 Tread Aluminum Sheet Plate

4017 tread aluminum plate combines aesthetics and functionality, with high surface gloss. It is often used in truck compartments and trailers, sidewalks and walkways, flooring, wall panels, and decorative trims in construction. Its good formability and weather resistance make it widely used in areas requiring anti-slip and decorative effects.

6061 Tread Aluminum Sheet Plate

6061 tread aluminum plate is a high-strength product with magnesium and silicon as the main alloying elements. In the 6061-T6 condition, it has excellent mechanical properties and corrosion resistance. Typical applications include sidewalks, flooring, ramps, bridge decks, channels and drainage covers, platforms, and stair treads, especially suitable for structural components that bear heavy loads.

5052-H32 Tread Aluminum Sheet Plate

5052-H32 tread aluminum plate uses magnesium as the main alloying element, featuring medium to high strength, good weldability, and excellent corrosion resistance, especially suitable for marine environments. Its surface offers various patterns such as diamond and five-bar designs, providing both anti-slip and decorative effects. It is widely used in ships, vehicles, and anti-slip flooring in construction.

Differences Between Tread Aluminum Sheet Plate Alloys

- 1xxx Series (Pure Aluminum): High electrical conductivity, corrosion resistance, easy to weld. Ideal for decorative applications and solar panels.

- 3xxx Series (Manganese Alloys): About 20% stronger than pure aluminum, suitable for construction and chemical equipment.

- 5xxx Series (Magnesium Alloys): Excellent corrosion resistance and high toughness, commonly used in marine environments and vehicle flooring.

- 6xxx Series (Magnesium-Silicon Alloys): Heat-treatable with excellent formability, commonly used in construction and automotive parts.

| Feature | 3003-H22 | 6061-T6 | 5052-H32 |

| Finish | Highly polished | Mill finish | Mill/Patterned |

| Strength | Moderate | High | Moderate to High |

| Corrosion Resistance | Good | Excellent | Excellent (Marine) |

| Common Applications | Decorative, Architectural | Industrial, Flooring | Marine, Structural |

Considerations for Choosing Tread Aluminum Sheet Plate Alloys

Selecting the appropriate aluminum alloy grade is crucial for the performance and service life of aluminum tread plates. Below are several key considerations:

- Application Environment: For humid or corrosive environments, 5xxx series alloys should be prioritized; for dry environments, 1xxx or 3xxx series alloys can be chosen.

- Strength Requirements: For applications requiring higher strength, select high-strength alloys such as 6061 or 5083.

- Processing Technology: Different alloys have varying processing performance. 1xxx and 3xxx series alloys are easier to process and weld.

- Surface Treatment Requirements: Certain surface treatment processes have specific requirements for alloy composition.

- Cost Consideration: Pure aluminum series are relatively lower in price, while alloy series are higher in cost.

Tread Aluminum Sheet Plate Specifications

Thickness Options for Tread Aluminum Sheet Plate

- .063"(1/16") tread aluminum plate

- .100" tread aluminum plate

- .125"(1/8") tread aluminum plate

- .188"(3/16") tread aluminum plate

- .250"(1/4") tread aluminum plate

- .375"(3/8") tread aluminum plate

- .500"(1/2") tread aluminum plate

Selection of Tread Aluminum Sheet Plate Specifications

- 1' x 1' (12 x 12) tread aluminum plate

- 1' x 2' (12 x 24) tread aluminum plate

- 1' x 4' (12 x 48) tread aluminum plate

- 1' x 10' (12 x 120) tread aluminum plate

- 1.5' x 10' (18 x 120) tread aluminum plate

- 2' x 2' (24 x 24) tread aluminum plate

- 2' x 4' (24 x 48) tread aluminum plate

- 2' x 5' (24 x 60) tread aluminum plate

- 2' x 6' (24 x 72) tread aluminum plate

- 2' x 8' (24 x 96) tread aluminum plate

- 2' x 10' (24 x 120) tread aluminum plate

- 3' x 3' (36 x 36) tread aluminum plate

- 3' x 4' (36 x 48) tread aluminum plate

- 3' x 10' (36 x 120) tread aluminum plate

- 4' x 4' (48 x 48) tread aluminum plate

- 4' x 8' (48 x 96) tread aluminum plate

- 4' x 10' (48 x 120) tread aluminum plate

- 5' x 8' (60 x 96) tread aluminum plate

Others

- Pattern: Common tread designs include diamond (5 bars), 3 bars, and compass (1 bar). The 5-bar tread dominates the North American market, especially suitable for plates with a thickness below 1.6 mm.

- Standard: Complies with ASTM B632 rolled tread plate standard to ensure uniformity of chemical composition and tensile properties.

Tread Aluminum Sheet Plate Patterns and Designs

Pattern Types Offered by Haomei Tread Aluminum Sheet Plate

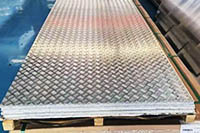

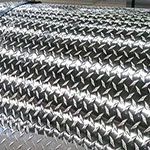

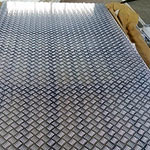

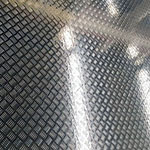

Five-Bar Tread (Willow Leaf Pattern)

- The surface has five raised rib patterns, arranged regularly, neat and elegant in appearance.

- The five-bar tread forms an angle of 60-80 degrees with other patterns, providing excellent anti-slip performance.

- Applications: Widely used for industrial workshop floors, stair treads, vehicle pedals, cold storage floors, etc.

- Specifications: Base width about 220 mm, spacing about 50 mm, commonly used thickness is 2.5-3.0 mm.

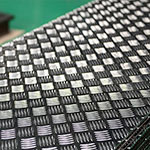

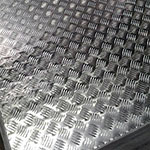

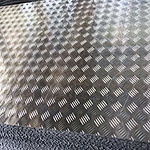

Diamond Pattern (Compass Pattern)

- The pattern shape resembles a pointer, offering strong decorative value while also providing good anti-slip performance.

- Applications: Provides a similar anti-slip effect as the five-bar tread but is relatively less frequently used.

- Specifications: Commonly used thickness is 2.0-3.0 mm.

Orange Peel Pattern

- The surface presents a texture similar to orange peel, with a delicate touch.

- Applications: Mainly used for decorative panels of household appliances such as refrigerators and air conditioners, as well as in packaging fields.

- Specifications: Commonly used thickness is 0.8-1.5 mm, width mostly ranges from 800-1220 mm.

Lentil Pattern

- The surface shows shapes similar to lentils, a commonly used style for anti-slip aluminum plates.

- Anti-slip Performance: Offers good anti-slip effect, mainly used for platforms and floors requiring slip resistance.

- Applications: Commonly used for vehicle compartment floors, platform anti-slip, cold storage floor anti-slip, etc.

Other Special Patterns

- Wave Pattern: The pattern is wave-like, with a sense of movement and streamlined aesthetics.

- Water Ripple Pattern: Simulates water ripple textures, providing unique visual effects.

- Pebble Pattern: The surface resembles pebbles, offering a unique tactile feel.

- Circular Pattern: Patterns in semicircular or circular shapes, with common thickness ranging from 1.0-3.5 mm.

- Three-Dimensional Triangle Pattern: Strong three-dimensional effect, good anti-slip performance, mainly used in special decorative applications.

Common Tread Aluminum Sheet Plate Patterns

- Diamond Pattern: Classic raised diamond patterns with anti-slip properties, widely used in flooring, wall panels, and decorative applications.

- Five-Bar Tread Plate: Uses a checkerboard arrangement of five raised bars, high strength, durable, suitable for heavy-duty applications such as truck beds and trailer floors.

- Special Patterns: Includes Fire Truck Quality (FTQ) diamond plate with serrated patterns for enhanced grip, stucco embossed patterns for decoration, and colored or anodized finishes to improve aesthetics and corrosion resistance.

Considerations for Pattern Selection

Choosing the right tread pattern is crucial for the performance of aluminum tread plates. Below are several factors to consider:

- Usage Environment: Humid or greasy environments require stronger anti-slip performance; five-bar or lentil patterns are recommended.

- Load Requirements: When higher load-bearing capacity is needed, choose patterns with higher structural strength, such as five-bar or spherical patterns.

- Aesthetic Needs: Decorative walls or high-end furniture can use pointer, orange peel, or water ripple patterns.

- Cleaning and Maintenance: Patterns with relatively smooth surfaces (such as orange peel) are easier to clean than deep-groove patterns.

- Processing Cost: Complex patterns generally require more advanced processing techniques, leading to higher costs.

Tread Aluminum Sheet Plate Surface Treatment

Common Surface Treatment Methods for Tread Aluminum Sheet Plate

The surface treatment of aluminum tread plates not only enhances their appearance but also improves corrosion resistance, wear resistance, and service life. Below are several common surface treatment methods:

Anodizing Treatment

- Forms an oxide film on the aluminum surface through an electrochemical process, with a typical thickness of 10-25 μm.

- The oxide film has high hardness, strong wear resistance and corrosion resistance, and is firmly bonded to the substrate.

- Can retain the natural color of aluminum, or obtain various colors through electrolytic coloring or dyeing processes.

- High-quality aluminum tread plates should have an oxide film thickness ≥10 μm to ensure sufficient corrosion resistance.

Powder Coating Treatment

- Dry powder coatings are electrostatically adsorbed onto the aluminum surface, then melted and leveled under high temperature.

- Coating thickness is typically 60-100 μm, offering good weather resistance, corrosion resistance, and wear resistance.

- Provides a wide range of color options, including solid colors, metallics, and special effect finishes.

- Relatively low cost, simple application, environmentally friendly, and free from volatile organic solvents.

Fluorocarbon Coating Treatment

- Uses coatings containing fluorocarbon resin, applied by spraying and baked at high temperatures to form a coating.

- Offers excellent weather resistance, corrosion resistance, and chemical resistance, suitable for long-term use in harsh environments.

- Provides a variety of colors, with long-lasting vibrant hues that are not easily faded.

- One of the most advanced surface treatment methods available, though with relatively higher costs.

Other Surface Treatment Methods

- Wood Grain Transfer Printing: Transfers wood grain patterns onto the aluminum surface through heat transfer technology.

- Brushed Finish: Creates fine linear textures on the aluminum surface using brushing equipment.

- Polishing Treatment: Uses mechanical or chemical polishing methods to achieve a mirror-like finish on the aluminum surface.

Haomei Available Surface Treatment Options for Tread Aluminum Sheet Plate

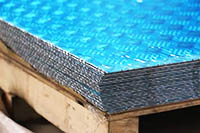

- Anodized Tread Aluminum Sheet Plate Anodized tread plates form a dense oxide film on the surface, enhancing corrosion and wear resistance, while giving the surface a finer and brighter texture. This product combines anti-slip functionality with decorative effects, commonly used in architectural decoration, transportation vehicles, and high-end interior and exterior decoration.

- Highly Polished Tread Aluminum Sheet Plate Highly polished tread plates are treated by mechanical or chemical polishing, giving the surface mirror-like brightness and reflectivity, creating a striking visual effect. With strong decorative appeal, they are widely used in commercial interiors, billboards, exhibition halls, and other environments requiring high reflectivity.

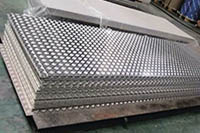

- Mill Finish Tread Aluminum Sheet Plate Mill finish tread plates retain the natural metallic color and texture of aluminum without additional surface treatment. They are economical and practical, with anti-slip and corrosion-resistant properties, commonly used for industrial floors, walkways, machinery panels, and structural parts where high surface decoration is not required.

- Bright Tread Aluminum Sheet Plate Bright tread plates are specially processed to give the surface higher gloss and brightness, combining aesthetics and practicality. They provide anti-slip performance while enhancing the overall visual effect, commonly used for vehicle interiors, building facades, flooring decoration, and interior design.

-

Red aluminum diamond tread plate

-

Grey aluminum diamond tread plate

Performance Comparison of Different Surface Treatment Methods for Tread Aluminum Sheet Plate

- Anodizing: Enhances corrosion resistance and provides decorative color options.

- Powder Coating: Cost-effective, wide color range, suitable for indoor use.

- Fluorocarbon Coating: Provides excellent weather resistance for outdoor applications.

| Finish | Corrosion Resistance | Aesthetics | Cost | Typical Use |

| Anodized | Excellent | Matte/satin | High | Outdoor structures, marine |

| Powder Coated | Moderate | Glossy | Moderate | Indoor furniture, electronics |

| Fluorocarbon | Superior | Custom colors | Highest | Architectural facades |

Guide to Surface Treatment Selection for Tread Aluminum Sheet Plate

Choosing the appropriate surface treatment method should take multiple factors into account. Below is a simple selection guide:

- Based on the usage environment: For outdoor environments, anodizing or fluorocarbon coating should be prioritized; for humid environments, ordinary paint should be avoided.

- Based on decorative needs: For a metallic texture, choose anodizing or brushed finish; for a rich color variety, choose powder coating or fluorocarbon coating.

- Based on maintenance needs: For low-maintenance requirements, choose anodizing; for easy-to-clean needs, choose fluorocarbon coating.

- Based on budget: For limited budgets, choose powder coating; for medium budgets, choose anodizing; for high budgets, choose fluorocarbon coating.

Tread Aluminum Sheet Plate Characteristics

- Anti-slip Performance: The patterned surface design significantly increases friction, effectively preventing slipping.

- Lightweight: Aluminum has low density, making aluminum tread plates lightweight and easy to handle and install.

- Corrosion Resistance: Aluminum easily forms a dense oxide film in air, providing good corrosion resistance.

- High Strength: By choosing different aluminum alloy grades, varying levels of strength can be achieved.

- Workability: Easy to cut, bend, stamp, and weld to meet the needs of different applications.

- Aesthetic and Decorative: The diverse tread patterns provide unique visual effects.

- Durability: Offers a long service life, reducing replacement and maintenance costs.

- Strength and Durability: Aluminum tread plates are lightweight yet strong, suitable for heavy-duty applications.

- Recyclability: Aluminum is highly recyclable, contributing to environmental sustainability.

Common Applications of Tread Aluminum Sheet Plate

Industrial Flooring

Used in factories, warehouses, and loading ramps due to its durability and anti-slip properties.

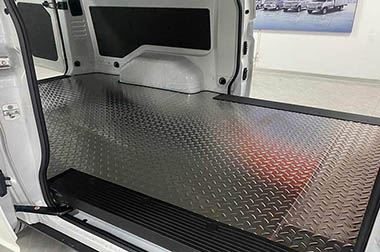

Vehicle Manufacturing

Lightweight yet strong, making it ideal for truck beds, trailers, and RV flooring.

Marine Environments

Suitable for ship decks, dock surfaces, and other areas exposed to humid environments.

Decorative Uses

Commonly used for wall cladding, decoration, and architectural features due to its aesthetic appeal.

Safety Applications

Used for stair treads, walkways, and emergency vehicles to enhance grip.

Construction

Stair treads, elevator interiors, and anti-slip flooring in commercial spaces.

Haomei Available Sizes and Purchasing of Tread Aluminum Sheet Plate

Standard Sizes:

- Common sizes include 2 ft x 8 ft, 4 ft x 8 ft, 4 ft x 10 ft, and 5 ft x 10 ft with thicknesses ranging from 0.039 inches (22 gauge) to 0.5 inches.

- Customization: Many suppliers offer cut-to-size options and custom shapes to meet specific project requirements.

Special Types

- Colored Aluminum Tread Plate: Available in colors such as red, achieved through painting or anodizing, for decorative purposes.

- Anodized Tread Plate: Offers enhanced corrosion resistance and durability, ideal for architectural and corrosive environments.

- Fire Truck Quality (FTQ) Tread Plate: Features serrated diamond patterns for enhanced anti-slip properties, used in emergency vehicles.

-

.063" (1/16) thick Aluminum Tread Plate 3003

Surface Finish: Highly Polished, Pattern: Diamond

-

.063" (1/16) thick - Extra Wide Aluminum Tread Plate 3003

Surface Finish: Highly Polished, Pattern: Diamond

-

.100" thickness Aluminum Tread Plate 3003

Surface Finish: Highly Polished, Pattern: Diamond

-

.125" (1/8) thick Aluminum Tread Plate 3003

Surface Finish: Highly Polished, Pattern: Diamond

-

.125" (1/8) thick - Extra Wide Aluminum Tread Plate 3003

Surface Finish: Highly Polished, Pattern: Diamond

-

.125" (1/8) thick Aluminum Tread Plate 6061

Surface Finish: Mill Finish, Pattern: Diamond

-

.188" (3/16) thick Aluminum Tread Plate 3003

Surface Finish: Highly Polished, Pattern: Diamond

-

.188" (3/16) thick Aluminum Tread Plate 6061

Surface Finish: Mill Finish, Pattern: Diamond

-

.250" (1/4) thick Aluminum Tread Plate 3003

Surface Finish: Highly Polished, Pattern: Diamond

-

.250" (1/4) thick - Extra Wide Aluminum Tread Plate 3003

Surface Finish: Highly Polished, Pattern: Diamond

-

.250" (1/4) thick Aluminum Tread Plate 6061

Surface Finish: Mill Finish, Pattern: Diamond

-

3/8" thick Aluminum Tread Plate 6061

Surface Finish: Mill Finish, Pattern: Diamond

-

1/2" thick Aluminum Tread Plate 6061

Surface Finish: Mill Finish, Pattern: Diamond

-

.063" (1/16) thick Aluminum Tread Plate 3003 H22

Surface Finish: Bright Finish, Pattern: 5 Bar

-

.063" (1/16) thick - Extra Wide Aluminum Tread Plate 3003 H22

Surface Finish: Bright Finish, Pattern: 5 Bar

-

.100" thickness Aluminum Tread Plate 3003 H22

Surface Finish: Bright Finish, Pattern: 5 Bar

-

.125" (1/8) thick Aluminum Tread Plate 3003 H22

Surface Finish: Bright Finish, Pattern: 5 Bar

-

.125" (1/8) thick - Extra Wide Aluminum Tread Plate 3003 H22

Surface Finish: Bright Finish, Pattern: 5 Bar

-

.125" (1/8) thick Aluminum Tread Plate 6061 T6

Surface Finish: Mill Finish, Pattern: 5 Bar

-

.188" (3/16) thick Aluminum Tread Plate 3003 H22

Surface Finish: Bright Finish, Pattern: 5 Bar

-

.188" (3/16) thick Aluminum Tread Plate 6061 T6

Surface Finish: Mill Finish, Pattern: 5 Bar

-

.250" (1/4) thick Aluminum Tread Plate 3003 H22

Surface Finish: Bright Finish, Pattern: 5 Bar

-

.250" (1/4) thick - Extra Wide Aluminum Tread Plate 3003 H22

Surface Finish: Bright Finish, Pattern: 5 Bar

-

.250" (1/4) thick Aluminum Tread Plate 6061 T6

Surface Finish: Mill Finish, Pattern: 5 Bar

-

3/8" thick Aluminum Tread Plate 6061 T6

Surface Finish: Mill Finish, Pattern: 5 Bar

-

1/2" thick Aluminum Tread Plate 6061 T6

Surface Finish: Mill Finish, Pattern: 5 Bar

-

3/16" Aluminum Tread Plate 4017

Surface Finish: Bright Finish, Pattern: 5 Bar

-

48" x 96" Aluminum Tread Plate 4017

Surface Finish: Bright Finish, Pattern: 5 Bar

-

0.0625" Aluminum Tread Plate 4017

Surface Finish: Bright Finish, Pattern: 5 Bar

-

0.19" Aluminum Tread Plate 4017

Surface Finish: Bright Finish, Pattern: 5 Bar

-

0.1" Aluminum Tread Plate 4017

Surface Finish: Bright Finish, Pattern: 5 Bar

-

0.08" Aluminum Tread Plate 5052

Surface Finish: Mill Finish, Pattern: 5 Bar

-

0.125" Aluminum Tread Plate 4017

Surface Finish: Bright Finish, Pattern: 5 Bar

-

0.25" Aluminum Tread Plate 5052

Surface Finish: Mill Finish, Pattern: 5 Bar

-

0.1875" Aluminum Tread Plate 4017

Surface Finish: Bright Finish, Pattern: 5 Bar

-

0.375" Aluminum Tread Plate 4017

Surface Finish: Bright Finish, Pattern: 5 Bar

-

0.5" Aluminum Tread Plate 5052

Surface Finish: Mill Finish, Pattern: 5 Bar

-

12" x 48" Aluminum Tread Plate 5052

Surface Finish: Mill Finish, Pattern: 5 Bar

-

24" x 48" Aluminum Tread Plate 5052

Surface Finish: Mill Finish, Pattern: 5 Bar

-

3/16" Aluminum Tread Plate 4017

Surface Finish: Mill Finish, Pattern: 5 Bar

How thick is aluminum tread plate?

The thickness of aluminum tread plates varies depending on the application and can be selected to meet different needs. Below are common thickness specifications and their applications:

Ultra-thin (0.1-0.8mm) aluminum tread plate

- Extremely thin thickness, lightweight, but lower strength.

- Applications: Mainly used for packaging materials, decorative panels, electronic device casings, etc.

- Thin (0.8-2.0mm) aluminum tread plate

- Provides certain strength and toughness, lightweight, with good processing performance.

- Applications: Commonly used in architectural decoration, automotive interiors, and furniture decoration.

- Specifications: Common thicknesses include 0.8mm, 1.0mm, 1.2mm, 1.5mm, and 2.0mm.

Medium (2.0-6.0mm) aluminum tread plate

- Moderate strength, with good load-bearing capacity and deformation resistance.

- Applications: Widely used in vehicle flooring, ship decks, stair treads, industrial platforms, etc.

- Specifications: Common thicknesses include 2.5mm, 3.0mm, 3.5mm, 4.0mm, 4.5mm, and 5.0mm.

Thick (6.0-25mm) aluminum tread plate

- High strength, excellent load-bearing and deformation resistance, but relatively heavier.

- Applications: Mainly used in scenarios requiring higher strength and stability, such as heavy machinery platforms.

Ultra-thick (25-250mm) aluminum tread plate

- Extremely high strength and load-bearing capacity, but difficult to process and costly.

- Applications: Mainly used in special engineering structures and industrial applications requiring extremely high strength.

Popular Types of Aluminum Tread Plate and Applications

These thicknesses may vary slightly depending on the manufacturer and the specific alloy used (such as 6061, 3003, or 4017).

Manufacturing Process

Rolling and Embossing: Produced by cold rolling with embossing rollers to form the surface patterns. One side remains smooth while the other side features raised designs.