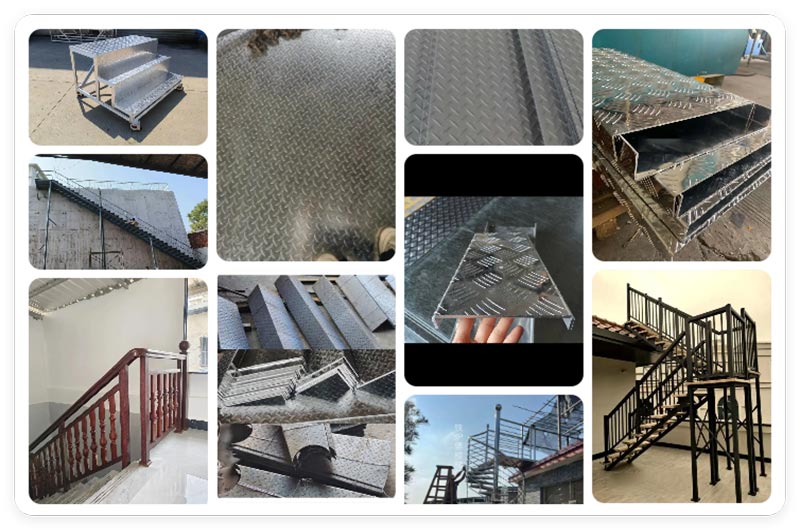

Aluminum diamond plate, as a stair tread material, is indeed a good choice due to its slip resistance, wear resistance, lightweight, and corrosion resistance. Aluminum Diamond Plate Stair Treads are widely used in industrial, commercial, and residential settings.

Anti-Slip Design

The surface is formed with diamond patterns or five-bar raised structures through casting or rolling processes, with pattern angles of 60–80 degrees, which effectively increase friction and reduce the risk of slipping, especially suitable for stair steps, floor platforms, and similar applications.

Diverse Specifications

Common thickness ranges from 0.5mm–20mm, with widths up to 1500mm. Customized shearing, slitting, and other processing services are available to meet different load-bearing and dimensional requirements.

Aluminum Diamond Plate Stair Treads Alloy Selection and Load Capacity

- 1000 Series (Pure Aluminum): Low cost, easy to process, suitable for low-load indoor stairs.

- 3000/5000 Series (Al-Mn / Al-Mg alloys): Excellent corrosion resistance; 5000 series maintains toughness at -40℃, suitable for coastal or cold regions.

- 6000 Series (Al-Mg-Si alloys): High strength, good wear resistance, commonly used for industrial platforms.

As stair tread material, the performance and characteristics of aluminum diamond tread plate mainly depend on the type of aluminum alloy used. Based on alloy composition and processing technology, the aluminum diamond plates commonly found on the market can be divided into the following categories:

Pure Aluminum Series (1xxx Aluminum Alloys)

Mainly includes grades such as 1060, 1050, and 1100, among which 1060 is the most commonly used pure aluminum material, with aluminum content up to 99.6%.

Features:

- Low density, lightweight, easy to carry and install

- Excellent corrosion resistance, especially against atmosphere and fresh water

- Good thermal and electrical conductivity, suitable for special applications requiring heat dissipation or electrical connection

- Excellent workability, easy cutting, bending, and welding

- Household stairs, indoor decoration, light-load locations

Al-Mn Alloy Series (3xxx Aluminum Alloys)

The 3xxx series mainly includes grades such as 3003, 3004, and 3105, among which 3003 is the most widely used alloy, containing about 1.2% manganese.

Features:

- Good corrosion resistance, especially against atmospheric and marine environments

- Higher strength than pure aluminum, about 1.5 times that of pure aluminum

- Excellent workability, suitable for deep drawing, bending, and other processing

- Bright surface appearance, also known as "tread brite"

- Commercial buildings, industrial staircases, welded structures

Al-Mg Alloy Series (5xxx Aluminum Alloys)

The 5xxx series mainly includes grades such as 5052, 5083, and 5754, among which 5052 and 5754 are commonly used for stair treads.

Features:

- High strength, especially excellent fatigue strength, among the better fatigue-resistant aluminum alloys

- Outstanding corrosion resistance, particularly against seawater and industrial atmospheres

- Good low-temperature toughness, maintaining good mechanical properties even in cold environments

- Better wear resistance than pure aluminum and 3xxx series alloys

- Marine environments, high-humidity areas, industrial staircases

Al-Mg-Si Alloy Series (6xxx Aluminum Alloys)

The 6xxx series mainly includes grades such as 6061, 6063, and 6082, among which 6061 is the most commonly used high-strength alloy.

Features:

- High strength, especially 6061-T6 after heat treatment, with tensile strength exceeding 290MPa

- Good corrosion resistance, superior to ordinary carbon steel

- Can be strengthened by heat treatment; T6 treatment significantly improves strength

- Excellent wear resistance, suitable for high-wear environments

- Industrial staircases, high wear resistance applications, heat-treated reinforcement

Aluminum Diamond Plate Stair Treads Material Selection Comparison Table

| Alloy Series | Typical Grades | Main Features | Strength Level | Corrosion Resistance | Workability | Price | Recommended Application Scenarios |

| Pure Aluminum Series | 1060, 1100 | Lightweight, good corrosion resistance, low cost | Low | Excellent | Excellent | Low | Residential stairs, light load areas |

| Al-Mn Series | 3003, 3105 | Medium strength, good corrosion resistance, weldable | Medium | Excellent | Excellent | Medium | Commercial buildings, decorative stairs |

| Al-Mg Series | 5052, 5754 | High strength, seawater corrosion resistance, cold workable | High | Excellent | Good | High | Marine environment, high humidity areas |

| Al-Mg-Si Series | 6061, 6082 | High strength, heat treatable, wear resistant | High | Good | Good | High | Industrial stairs, demanding buildings |

Corrosion Resistance and Service Life of Aluminum Diamond Plate Stair Treads

Aluminum alloys have inherent corrosion resistance. After anodizing, the oxide film thickness can reach 10-20μm, with salt spray test exceeding 1000 hours, giving a service life of 5-8 years. In chemical or coastal corrosive environments, it is recommended to use 5052-H32 or 6061-T6 alloys.

Common Surface Treatments of Aluminum Diamond Plate Stair Treads and Their Effects

The surface treatment of aluminum diamond plate stair treads directly affects their appearance, slip resistance, corrosion resistance, and service life. Different surface treatments are suitable for different environments and requirements.

Anodizing

Forms an aluminum oxide film on the surface through electrolytic oxidation, enhancing corrosion resistance and wear resistance.

Effect Features:

- Improved corrosion resistance: oxide film thickness usually 15-25μm

- Enhanced wear resistance: oxide film hardness up to 300-500HV

- Good appearance: can form multiple colors, aesthetically pleasing

- High surface hardness: up to 2-3H, much harder than untreated aluminum

- Outdoor stairs, humid environments, industrial stairs

Color Coating

Applies colored organic coatings evenly on the aluminum substrate, cured at low temperature to form a colored film.

Effect Features:

- Rich and precise colors: customizable in solid, gradient, wood grain, stone grain, etc.

- Good decorative effect: matches overall architectural style, enhances stair aesthetics

- Moderate weather resistance: outdoor use 3-5 years, indoor use can last over 10 years

- Easy to clean: stains can be wiped off directly with a damp cloth

- Surface hardness: up to 1-2H, resistant to daily light friction

- Indoor stairs, shopping mall stairs, office building stairs

Polishing

Removes oxide layer and surface defects by mechanical or chemical polishing to achieve a smooth surface.

Effect Features:

- High surface smoothness: mechanical polishing can achieve mirror effect

- Improved appearance: highlights natural metallic luster, premium look

- Auxiliary corrosion resistance: smooth surface reduces impurities adhesion, slightly improves oxidation resistance

- High surface smoothness: no unevenness after treatment, smooth walking feel

- Indoor stairs, showroom stairs, residential stairs

Anti-Slip Coating

Applies a high-friction material coating on the aluminum surface to enhance slip resistance.

Effect Features:

- High friction coefficient: dry state up to 0.6-0.8, wet state up to 0.4-0.6

- Excellent slip resistance: significantly reduces slip accidents

- Elastic touch: some coatings are elastic, improving walking comfort

- Customizable: friction particle size and distribution can be adjusted as needed

- Humid environments, kitchens, hospitals

Fluorocarbon Coating

Uses fluoropolymer coatings with excellent weather resistance and chemical stability.

Effect Features:

- Superior weather resistance: can last over 20 years outdoors without fading

- Extremely high chemical stability: strong resistance to acids, alkalis, and salts

- Self-cleaning: some fluorocarbon coatings have self-cleaning properties

- High gloss: can achieve glossy or matte finishes, aesthetically pleasing

- High-end buildings, harsh environments, chemical plants

Powder Coating

Powder coatings are electrostatically adsorbed onto the aluminum surface and then cured at high temperature to form a protective film.

Effect Features:

- Rich color options: almost all colors available

- Good weather resistance: long-lasting in outdoor environments without fading

- High corrosion resistance: good resistance to acids, alkalis, and salts

- Moderate surface hardness: up to 2-3H, sufficient for general use

- Commercial buildings, decorative stairs, residential stairs

-

Red aluminum diamond tread plate

-

Grey aluminum diamond tread plate

Aluminum Diamond Plate Stair Treads Surface Finish Selection Guide

| Treatment Method | Main Advantages | Main Disadvantages | Suitable Applications |

| Anodizing | Strong corrosion resistance, good wear resistance, long-lasting color, attractive appearance | Higher cost, limited color options, difficult to repair | Outdoor stairs, humid environments, marine environments |

| Powder Coating | Wide color options, good weather resistance, strong corrosion resistance, easy application | Less wear resistant than anodizing, may discolor under high temperatures | Commercial buildings, decorative stairs, residential stairs |

| Fluorocarbon Coating | Extremely strong weather resistance, high chemical stability, good self-cleaning properties, attractive appearance | Very high cost, complex process, requires professional equipment | High-end commercial buildings, landmark buildings, harsh environments |

| Anti-Slip Coating | Excellent anti-slip performance, high customization, wide color options, easy application | Average wear resistance, limited service life, prone to aging under long-term exposure | Humid environments, kitchens, hospitals, nursing homes |

| Mechanical Treatment | Simple process, relatively low cost, customizable as needed | Limited anti-slip performance, limited surface treatment depth | Commercial places, exhibition halls, decorative stairs |

Haomei Aluminum Diamond Plate Specs and Options

| Item | Description |

| Main Material | Common aluminum alloy grades such as 5052, 3003, 4017, 6061, 1060, with good rust resistance and weather resistance. |

| Common Specifications | Thickness ranges from 1–3mm (civil use) to thicker options (industrial use); width and length can be customized. Diamond patterns provide anti-slip performance. |

| Surface Treatment | Can undergo anodizing, spraying, and other treatments to enhance corrosion resistance and aesthetics. |

| Main Advantages | Excellent slip resistance, corrosion resistance, lightweight and durable, relatively easy installation, and simple maintenance. |

| Application Scenarios | Warehouses, workshops, power plants, commercial facilities, outdoor staircases, or other areas requiring anti-slip properties. |

Advantages and Disadvantages of Aluminum Diamond Plate Stair Treads

| Aspect | Advantages | Disadvantages |

| Safety | Patterned design provides excellent slip resistance, safer in rainy or oily environments | If the patterned surface wears out or accumulates dirt, the anti-slip effect may decrease |

| Durability | Good corrosion resistance, rust resistance; excellent wear resistance with a long service life | Aluminum alloy hardness is relatively lower than steel, heavy impact or scratches may leave marks |

| Weight & Installation | Lightweight material, easier to handle and install, lower load requirements on stair structures | Installation requires professional fixing techniques (such as welding or using specific fasteners); improper installation may cause noise or looseness |

| Maintenance & Cleaning | Simple daily cleaning and maintenance | The raised diamond pattern can easily trap dust and grease, requiring regular thorough cleaning |

| Aesthetics & Cost | Metallic texture with a modern industrial look; surface can be treated (anodizing, spraying, etc.) | Raw material cost is higher than ordinary steel plate or concrete stairs; appearance style may not suit all interior designs |

Aluminum diamond plate stair treads excel in safety (anti-slip), durability (corrosion and wear resistance), and lightweight properties. They are especially suitable for industrial-style and modern minimalist designs, as well as outdoor and humid environments, weight-sensitive applications, and high-traffic public areas.

Applicable Scenarios and Pros & Cons of Different Thicknesses of Aluminum Diamond Plate Stair Treads

The thickness of aluminum diamond plate directly affects the load-bearing capacity, durability, and cost of stair treads. Choosing the correct thickness is crucial for ensuring the safety and cost-effectiveness of stairs.

Common thickness specifications and suitable scenarios

1.0-2.0mm Thickness:

Advantages: lightweight, low cost, easy to process, convenient installation

Disadvantages: limited load-bearing capacity, easy to deform, poor wear resistance

Suitable scenarios:

- Residential stairs, especially in light-load applications

- Decorative stairs, mainly for appearance rather than heavy load-bearing

- Temporary or movable stairs

- Scenarios with strict weight requirements, such as mobile stages

2.0-3.0mm Thickness:

Advantages: medium weight, moderate cost, relatively good load-bearing capacity, moderate wear resistance

Disadvantages: not suitable for heavy loads, may deform after long-term use

- Ordinary commercial building stairs, such as offices and small shopping malls

- Residential stairs with frequent usage

- Stairs in light industrial environments, such as small factories and warehouses

- Scenarios requiring balance between weight, cost, and strength

3.0-5.0mm Thickness:

Advantages: good load-bearing capacity, relatively good wear resistance, moderate weight and cost

Disadvantages: relatively heavy, higher cost, more difficult to process

- Industrial workshop stairs, especially where equipment is moved

- Public building stairs, such as schools, hospitals, and large shopping malls

- Commercial parking lot stairs

- Frequently used stairs, such as main office building stairs

- Locations with high safety requirements

5.0-8.0mm Thickness:

Advantages: high strength, strong load-bearing capacity, excellent wear resistance, long service life

Disadvantages: heavy weight, high cost, difficult to process, complex installation

- Stairs in heavy industrial environments, such as large factories and mines

- High-load stairs, such as freight passage stairs

- Work platform stairs around special equipment

- Locations requiring high safety and durability

- Spiral stairs inside wind power towers

Above 8.0mm Thickness:

Advantages: extremely high strength and load-bearing capacity, excellent wear resistance, extra-long service life

Disadvantages: extremely heavy, very high cost, very difficult processing and installation

- Special industrial environments, such as heavy machinery plants and foundries

- Military facilities with high stair requirements

- Stairs for large equipment maintenance platforms

- Special places with extremely high safety requirements

Comparison of Comprehensive Performance of Different Thicknesses

| Thickness Range | Load-bearing Capacity | Wear Resistance | Weight | Cost | Processing Difficulty | Applicable Scenarios |

| 1.0-2.0mm | Low | Poor | Light | Low | Easy | Residential, decorative stairs |

| 2.0-3.0mm | Medium | Medium | Medium | Medium | Medium | Commercial buildings, general offices |

| 3.0-5.0mm | High | Good | Heavy | High | Difficult | Industrial plants, public buildings |

| 5.0-8.0mm | Very High | Excellent | Very Heavy | Very High | Very Difficult | Heavy industry, high-load areas |

| Above 8.0mm | Ultimate | Outstanding | Ultra-heavy | Very High | Very Difficult | Special industries, military facilities |

Application Scenarios

- Construction field: Used in stair treads, floor platforms, corridors and other anti-slip areas, combining functionality and aesthetics

- Industrial applications: Suitable for automobile manufacturing, machinery processing, rail transit and other places requiring wear resistance and anti-slip performance

Aluminum Diamond Plate Stair Treads Material Selection Method

Choose the appropriate aluminum alloy material according to usage requirements and environmental conditions:

Select by strength requirements:

- Low strength requirements: Choose pure aluminum series (1xxx) or 3xxx alloys

- Medium strength requirements: Choose 3xxx or 5xxx alloys

- High strength requirements: Choose 6xxx alloys, such as 6061-T6

- Ultra-high strength requirements: Choose 7xxx alloys, such as 7075

Select by corrosion resistance requirements:

- General environment: Choose pure aluminum series or 3xxx alloys

- Humid environment: Choose 5xxx alloys, such as 5052 or 5754

- Marine environment: Choose 5xxx alloys, such as 5083 or 5754

- Chemical environment: Choose alloys with strong corrosion resistance based on the type of chemical substances

Select by processing performance requirements:

- Requires bending or stamping: Choose pure aluminum series or 3xxx alloys, with good formability

- Requires welding: Choose 5xxx alloys, such as 5052 or 5083, with good welding performance

- Requires machining: Choose 6xxx alloys, such as 6061, with good machinability

- Requires heat treatment strengthening: Choose 6xxx alloys, which can be strengthened through T6 treatment

Select by cost budget:

- Low budget: Choose pure aluminum series or 3xxx alloys, with lower cost

- Medium budget: Choose 5xxx alloys, such as 5052, with high cost-effectiveness

- High budget: Choose 6xxx or 7xxx alloys, with excellent performance

Comprehensive Recommendations:

- Residential Stairs: Recommend 1060 or 3003 aluminum alloy, balancing cost and performance

- Commercial Buildings: Recommend 6061-T6 aluminum alloy, offering good strength and aesthetics

- Industrial Stairs: Recommend 6061-T6 or 5052 aluminum alloy, providing excellent strength and corrosion resistance

- Outdoor Stairs: Recommend 5754 or 5083 aluminum alloy, with good weather resistance

- Marine Environments: Recommend 5083 or 5754 aluminum alloy, resistant to seawater corrosion

Precautions for Purchasing Aluminum Diamond Plate Stair Treads

- Confirm Thickness and Load Capacity: Ensure that the thickness of the tread plate meets the load-bearing requirements of the actual application. In high-traffic public areas, choose thicker plates with higher strength.

- Pay Attention to the Diamond Pattern: The size and raised height of the diamond pattern directly affect the anti-slip effect. The higher the raised pattern, the better the slip resistance, but it also tends to accumulate dust and dirt more easily.

- Inquire About Edge Treatment: The edges of the tread plate should be folded or rolled. This not only increases the strength of the tread plate and prevents warping but also reduces safety hazards caused by sharp edges.

- Understand the Installation Method: Confirm whether the tread plate design is easy to install, whether additional fasteners or clips are required, and whether special treatment of the original stair base is necessary.

Aluminum diamond plate stair treads are highly functional materials. Their anti-slip, durable, and corrosion-resistant properties make them particularly suitable for industrial environments, humid areas, or outdoor locations.