Using aluminum diamond plate for trailer flooring has become a common industry choice. Aluminum diamond plate (especially 5083 five-bar tread plate) is an ideal material for high-end trailers, refrigerated trucks, and box trucks. Although its initial procurement cost is higher than steel and wood, the advantages of lightweight design (increased payload capacity), extended service life, and nearly zero maintenance costs make it more economical in terms of total lifecycle cost.

When selecting aluminum diamond plate, it is necessary to consider trailer type, transportation environment, and budget.

- For heavy-duty or high-corrosion scenarios, the combination of 6061-T6 with anodizing is the most cost-effective solution.

- For lightweight or high-aesthetic requirements, 3003-H22 is more suitable.

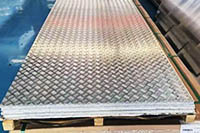

Aluminum Diamond Plate Trailer Floor Features and Advantages

Lightweight Design

Aluminum diamond plate weighs only about one-third of steel, effectively reducing the overall trailer weight, improving cargo efficiency, and lowering fuel consumption.

Slip Resistance and Load-Bearing Performance

Patterns such as five-bar and lentil-shaped designs provide excellent anti-slip effects, especially suitable for transporting slippery goods. 5052/5083 aluminum-magnesium alloy diamond plates can bear loads of over 4 tons, with high surface hardness and strong impact resistance.

Corrosion Resistance and Durability

Aluminum-magnesium alloy diamond plates do not easily rust in humid or salty environments. Their maintenance-free characteristic reduces long-term operating costs.

Alloy Selection and Performance Differences

Common aluminum alloys include 3003, 5086, and 6061. Among them, 3003-H22 has high corrosion resistance and gloss, suitable for trailers that need to be exposed to humid environments for a long time (such as cold-chain transport). 6061-T6 has higher strength but slightly weaker corrosion resistance, suitable for heavy-duty trailers. For example, a 6-ton aluminum diamond plate trailer uses 6061 material, with a platform size of 4.98×2.2 meters, capable of carrying over 6 tons of cargo.

Pattern Design and Anti-Slip Performance

Five-bar tread plate (willow leaf pattern) is the mainstream choice for trailer floors. Its raised ridges form a 60-80 degree angle, with a wet friction coefficient of 0.4-0.5, effectively preventing cargo from sliding. Diamond pattern, on the other hand, breaks through water films with sharp edges, further enhancing slip resistance in wet environments, achieving a dry friction coefficient of 0.7-0.8.

Corrosion Resistance and Maintenance Costs

The natural oxide film of aluminum can resist salt spray and acid-alkali erosion. In coastal areas, it is recommended to rinse the surface salt with fresh water monthly. Anodizing can improve corrosion resistance by 3-5 times, making it suitable for trailers transporting chemicals. Compared with carbon steel, aluminum diamond plate does not require regular painting, reducing maintenance costs by over 40%.

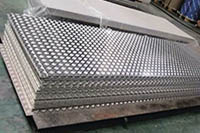

Aluminum Diamond Plate Trailer Floor Material Options and Dimensions

When choosing the size of aluminum diamond plate for trailer floors, there are several important factors to consider, including the size of the trailer, its intended use, and load capacity.

Common Aluminum Alloys for Trailer Floors

5083-H321 or 5052-H32. 5083 has higher strength and better corrosion resistance, making it the preferred choice. 5052 is slightly lower in cost, yet strong enough to meet most requirements.

Common Aluminum Tread Plate Types for Trailer Floors

For trailer flooring, the most common type is five-bar tread plate.

Pattern: The surface has five raised bar-shaped patterns, three grouped together, separated by two in between.

Aluminum Diamond Plate Trailer Floor Size

Common trailer widths typically range from 4 to 8 feet (approximately 1.2 to 2.4 meters), and lengths can vary from 4 feet (approximately 1.2 meters) to 30 feet (approximately 9 meters) or longer. When selecting aluminum diamond plate, first measure the specific dimensions of the trailer to ensure the plate can fully cover the floor.

Measure the length and width of the trailer floor to determine how much diamond plate is needed.

Common sheet sizes include 4x8 feet and 4x10 feet, but custom sizes are also available.

Aluminum Diamond Plate Trailer Floor Thickness

The thickness of aluminum diamond plate typically ranges from 1/8 inch (approximately 3.2 mm) to 1/4 inch (approximately 6.4 mm). For trailer floors, it is recommended to choose aluminum diamond plate with a thickness between 1/8 and 1/4 inch to ensure its load-bearing capacity and durability.

- 1/8 inch (3.2 mm): Suitable for light-duty trailers or trailers carrying lighter loads.

- 1/4 inch (6.35 mm): Suitable for general use, providing a balance between weight and strength.

- 3/8 inch (9.5 mm) or thicker: Recommended for heavy-duty trailers or trailers expected to carry larger weights.

Common thickness options for aluminum diamond plate trailer flooring include …

According to the trailer’s load requirements and the spacing of cross beams under the floor, commonly used thicknesses are 3mm, 4mm, and 5mm.

- Light-duty vehicles: 2.5mm - 3.0mm

- Standard box trucks / stake trucks: 3.0mm - 4.0mm

- Heavy-duty containers, requiring forklift operations: 4.0mm - 5.0mm or thicker

Aluminum Diamond Plate Trailer Floor Surface Treatments

- Mill Finish: Most common, keeping the natural metallic appearance of aluminum.

- Anodizing: Adds a thicker and harder oxide film, further improving corrosion and wear resistance, while enhancing appearance.

- Coating: Less common, mainly for special appearance needs, but may reduce slip resistance.

Options include raw aluminum or anodized aluminum plates, the latter of which offers a wider range of color choices and enhanced wear resistance.

-

Red aluminum diamond plate

-

Grey aluminum diamond plate

Load-Bearing Capacity

Thicker aluminum diamond plates can support greater weights, suitable for transporting heavy items. For light-duty trailers, thinner sheets may be sufficient.

Practical Applications of Aluminum Diamond Plate in Trailer Flooring

- Freight Trailers: Used for flatbed trailer platforms, paired with detachable cable racks and movable wheel seats, suitable for transporting construction equipment, building materials, etc.

- Special Vehicles: Tent-style RVs adopt double-layer aluminum diamond plate floors, combining lightweight design with structural stability.

- Cold Chain Transport: Anti-rust aluminum diamond plate (such as 3003 alloy) is suitable for fresh food transport trucks, preventing condensation corrosion.

Why Choose Aluminum Diamond Plate for Trailer Floors?

Lightweight

- This is one of the biggest advantages. The density of aluminum alloy is about one-third that of steel, significantly reducing trailer weight.

- Benefit: In cases where regulations strictly limit total vehicle weight, lighter trailer weight means carrying more cargo, directly improving transport efficiency and economic benefits.

Excellent Corrosion Resistance

- The surface of aluminum alloy forms a dense oxide film that effectively resists corrosion from air, rain, and possible substances carried by cargo.

- Benefit: Long service life, extremely low maintenance cost, unlike steel floors that require frequent anti-rust painting, making it especially suitable for box trucks, refrigerated trucks, and bulk cargo trucks.

Outstanding Slip Resistance

- The raised patterns on the plate surface provide excellent friction, ensuring safety for both personnel movement and cargo stability, effectively preventing slipping.

- Benefit: Protects the safety of loading/unloading personnel and prevents cargo from shifting during transport due to bumps.

High Strength and Durability

- Common 5xxx series aluminum alloys (such as 5083, 5086, 5454) are aluminum-magnesium alloys with excellent fatigue resistance and load-bearing capacity, able to withstand forklifts, cargo pressure, and impacts.

- Benefit: Strong and durable flooring that resists deformation and adapts to harsh transport conditions.

Easy Processing and Maintenance

- Aluminum alloy is easy to cut, drill, and bend (with proper techniques), making it convenient for installation and customization in trailer manufacturing.

- The surface is easy to clean, simply rinse with water, unlike wooden floors that rot or harbor bacteria.

Environmental and Recycling Value

Aluminum alloy is 100% recyclable, with high recycling value, aligning with environmental trends.

Tips for Selecting Aluminum Diamond Plate Trailer Floors

Key factors to consider when selecting:

Alloy Grade and Temper:

Prioritize 5083-H321, which offers the best balance of strength, corrosion resistance, and weldability.

Thickness:

Must be determined based on the trailer’s design load and the spacing of support cross beams. The larger the spacing, the thicker the plate required to prevent sagging. Always consult the trailer manufacturer or aluminum supplier for professional advice.

Dimensions:

Aluminum diamond plates come in standard widths (such as 1000mm, 1250mm, 1500mm) and lengths (such as 2000mm, 2500mm, 3000mm and above). Cutting and sizing must be done according to the specific trailer body dimensions.

Material Selection

- General Freight: 1060 aluminum diamond plate (economical choice)

- High-humidity environments: 5052/5083 aluminum-magnesium diamond plate (enhanced rust resistance)

Thickness Reference

Commercial trailers are recommended to use plates with thicknesses above 1.5mm. Some models use a double-layer 1.5mm design. For higher load-bearing requirements, plate thickness or frame reinforcement must be increased.