Aluminium IBR (Inverted Box Rib) roof sheeting is a corrugated roofing material widely used in industrial and commercial buildings due to its durability, lightweight, and corrosion resistance.

- Aluminium IBR roof panels are favored for their high strength, lightweight, and corrosion resistance.

- Haomei Aluminium IBR roof sheeting offers customized sizes, colors, and coatings to meet diverse project requirements, ensuring durability, functionality, and an attractive appearance for your roofing solutions.

- Aluminium IBR roof sheeting is an economical and aesthetically pleasing solution suitable for a variety of building applications.

Aluminium IBR Roof Sheeting Technical Specifications

- Material: Aluminium alloy (AA 3004 / 3105 / 5052 options available)

- Profile: Inverted Box Rib (IBR) trapezoidal design

- Thickness: 0.4 mm – 0.8 mm (customizable)

- Effective Cover Width: 686 mm (standard)

- Sheet Length: Cut-to-size (up to 13 m, depending on transport)

- Coating Options: Mill finish, polyester paint, PE/PVDF coating, or anodized

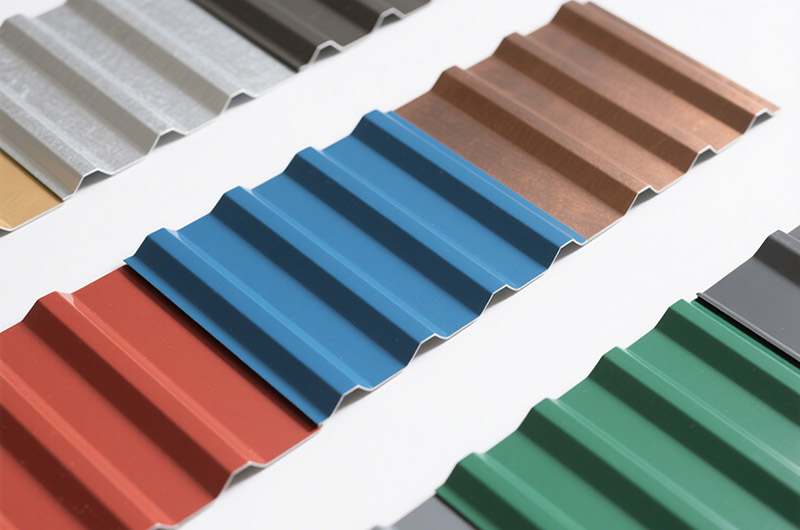

- Color Range: Natural aluminium silver, white, grey, blue, green, red, and custom RAL colors

Thickness

- 0.4 mm

- 0.45 mm

- 0.5 mm

- 0.55 mm

- 0.6 mm

- 0.7 mm

- 0.8 mm

Effective Cover Width

- Standard: 686 mm (most common)

- Optional: 610 mm / 762 mm (depending on manufacturer or project requirements)

Sheet Length

Cut-to-size based on project needs

Typical range: 2 m – 13 m

Longer lengths may be available for large industrial projects

Rib Profile

- Rib height: 18 mm – 35 mm (common for IBR)

- Rib spacing: 76 mm – 150 mm (depending on load requirements)

Color Options

Natural aluminium (silver)

White, grey, blue, green, red

Custom RAL colors available

-

Silver Aluminum IBR Roof Sheeting

-

White Aluminum IBR Roof Sheeting

-

Blue Aluminum IBR Roof Sheeting

-

Green Aluminum IBR Roof Sheeting

-

Red Aluminum IBR Roof Sheeting

-

Bronze Aluminum IBR Roof Sheeting

-

Grape Purple Aluminum IBR Roof Sheeting

Aluminium IBR Roof Sheeting Material Properties

IBR panels can be made from high-quality aluminium alloys such as 3004, 5052, 6061, 1060, 1070, combining strength and lightweight performance. They can be flexibly applied to various roof sizes and designs. The natural oxide layer of the material provides inherent corrosion resistance, making it ideal for coastal areas or high-humidity environments.

IBR roof panels are made of premium aluminium, lightweight, weather-resistant, and energy-efficient. They reflect sunlight, reducing heat absorption and helping lower energy costs. They are corrosion-resistant, durable, and suitable for harsh environments.

Aluminium IBR Roof Sheeting Structural Design

"IBR" refers to its unique trapezoidal rib design, forming inverted box channels that enhance structural integrity and optimize drainage performance. This structure is especially effective in areas with heavy rainfall, as efficient drainage is critical in such regions.

IBR profiles typically include U-shaped cavities for panel fastening, with intermediate flanges parallel to the top/bottom flanges to ensure stability. This profile provides excellent structural integrity and drainage performance, making it an ideal choice for roofing applications.

Aluminium IBR Roof Sheeting Customization Options

- Size and Thickness: Length, width (e.g., 665 mm – 1000 mm), and thickness (e.g., 0.3 mm – 1.2 mm) can be customized to meet specific project requirements.

- Color and Coating: Options include glossy, embossed, painted (e.g., PE or PVDF coating), and custom colors (e.g., red, grey, blue, etc.).

- Alloy and Temper: Common alloys include 1060, 3003, 5052, with tempers such as H24, O, T6, to achieve the required mechanical properties.

Aluminium IBR Roof Sheeting Features

- Corrosion Resistance — Aluminium naturally resists rust, ensuring a longer service life even in coastal or high-humidity environments.

- Lightweight — Easier to transport and install compared to steel.

- High Strength-to-Weight Ratio — Provides structural stability without adding unnecessary load.

- Aesthetic — Clean, modern appearance with multiple finish options.

- Low Maintenance — Very low long-term maintenance costs.

Aluminium IBR Roof Sheeting Advantages

- Durability: Weather-resistant, wind and rain-resistant, and corrosion-resistant, ensuring long-term performance.

- Cost-Effective: Low maintenance costs, long service life, reducing overall expenses.

- Aesthetic Appeal: Offers a variety of colors and finishes, enhancing building appearance.

The deep ribs of the IBR profile enhance load-bearing capacity, allowing the panels to withstand strong winds and moderate snow loads. Unlike traditional corrugated roofs, the inverted box design minimizes oil canning (surface waviness) and ensures a smooth, uniform appearance.

The anti-rust property of aluminium (forming a protective oxide layer instead of corroding) allows IBR panels to withstand harsh weather conditions. They resist salt spray, UV radiation, and extreme temperatures, with a normal service life exceeding 50 years. Compared to steel or asphalt alternatives, this durability means less maintenance.

Aluminium IBR Roof Sheeting Applications

Widely used for residential roofs, industrial warehouses, agricultural buildings, commercial facilities, and sidewall cladding.

Aluminium IBR Roof Sheeting, due to its versatility and aesthetic appeal, is suitable for both new construction and renovation projects.