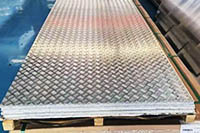

4mm aluminum checker plate, often referred to as aluminum tread plate or diamond plate, is a versatile and lightweight sheet material characterized by its distinctive raised pattern, typically in a diamond or five-bar design.

The 4mm aluminium checker plate achieves a balance between strength and weight, making it suitable for various applications in industries such as construction, transportation, and manufacturing.

Features of 4mm Aluminium Checker Plate

- Strength and Durability: Despite its thinner profile, the 4mm checker plate provides sufficient structural integrity for many applications, making it suitable for medium load requirements.

- Corrosion Resistance: With its protective oxide layer, aluminium is naturally resistant to corrosion, making this material ideal for outdoor and industrial environments that frequently encounter moisture and chemicals.

- Lightweight: Aluminium is much lighter than steel, making it easier to handle, transport, and install in various applications without compromising strength.

- Slip Resistance: The raised pattern on the surface enhances traction, making the 4mm checker plate particularly suitable for areas where slip resistance is critical, such as walkways, ramps, and stair treads.

Specifications of 4mm Aluminium Checker Plate

- Pattern Options: Common patterns include diamond and five-bar designs, which improve grip and add a decorative element to the surface.

- Surface Finish: Available in different finishes, such as mill finish, anodized, or powder-coated, which enhance its durability and aesthetic appeal. Anodizing can provide additional protection against scratches and wear.

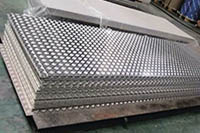

- Custom Sizes: 4mm checker plates can be manufactured in various dimensions and can be easily cut to size, providing flexibility for specific applications.

4mm Aluminium Checker Plate Pattern Options

- Diamond (5-bar): Most commonly used for anti-slip applications, featuring raised diamond-shaped ribs.

- Diamond (1-bar): Linear ribs designed for directional grip, used for sidewalks and ramps.

- Orange Peel Texture: A decorative texture with small dimples, often used for interior decoration.

- Pattern Height: Typically raised 0.2–0.5 mm above the base plate to ensure grip while maintaining a slim profile.

4mm Aluminium Checker Plate Surface Finish Options

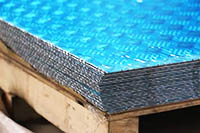

- Anodized: Enhances corrosion resistance and provides a matte or glossy finish. Common for outdoor applications .

- Painted/Coated: Available in custom colors for aesthetics or additional protection (e.g., polyester or fluorocarbon coatings) .

- Mill Finish: Uncoated surface with natural aluminum appearance, suitable for indoor use.

-

Red aluminum diamond tread plate

-

Grey aluminum diamond tread plate

4mm Aluminium Checker Plate Size Options

- 1' x 1' (12 x 12) aluminum diamond checker plate

- 1' x 2' (12 x 24) aluminum diamond checker plate

- 1' x 4' (12 x 48) aluminum diamond checker plate

- 1' x 10' (12 x 120) aluminum diamond checker plate

- 1.5' x 10' (18 x 120) aluminum diamond checker plate

- 2' x 2' (24 x 24) aluminum diamond checker plate

- 2' x 4' (24 x 48) aluminum diamond checker plate

- 2' x 5' (24 x 60) aluminum diamond checker plate

- 2' x 6' (24 x 72) aluminum diamond checker plate

- 2' x 8' (24 x 96) aluminum diamond checker plate

- 2' x 10' (24 x 120) aluminum diamond checker plate

- 3' x 3' (36 x 36) aluminum diamond checker plate

- 3' x 4' (36 x 48) aluminum diamond checker plate

- 3' x 10' (36 x 120) aluminum diamond checker plate

- 4' x 4' (48 x 48) aluminum diamond checker plate

- 4' x 8' (48 x 96) aluminum diamond checker plate

- 4' x 10' (48 x 120) aluminum diamond checker plate

- 5' x 8' (60 x 96) aluminum diamond checker plate

Common Alloys for 4mm Aluminium Checker Plate

For 4mm aluminium checker plate, the most commonly used alloys are 3003, 5052, and 6061, each tailored to specific performance requirements.

Alloy 3003

- Composition: Al-Mn alloy (manganese content 1–1.5%), with excellent corrosion resistance and formability.

- Temper: Typically H22 (strain-hardened and partially annealed) to balance strength and workability.

Key Features:

- Decorative: Known for its bright surface, often used in architectural decoration, signage, and decorative flooring.

- Corrosion Resistance: Suitable for indoor or mild outdoor environments, such as truck toolboxes and cargo vehicles.

- Formability: Easy to bend or weld, making it ideal for custom fabrication projects.

- Limitation: Lower strength compared to 5052 or 6061, making it less suitable for heavy-duty structural applications.

Alloy 5052

- Composition: Al-Mg alloy (Mg content 2.2–2.8%), with high corrosion resistance and medium strength.

- Temper: Commonly H32 (strain-hardened and stabilized) to enhance durability.

Key Features:

- Marine Grade: Resistant to seawater and humid environments, widely used in ship decks, offshore platforms, and refrigerated trucks.

- Strength: Tensile strength (230–280 MPa) is higher than 3003, suitable for medium-load applications such as loading ramps and trench covers.

- Workability: Retains good formability even after heat treatment, allowing complex shapes for specialized designs.

- Applications: Refrigerated flooring, marine hardware, and industrial flooring where anti-slip and corrosion resistance are critical.

Alloy 6061

- Composition: Al-Mg-Si alloy (0.8–1.2% Mg, 0.4–0.8% Si), offering high strength and weldability.

- Temper: T6 (solution heat-treated and artificially aged) is the standard condition for maximum strength.

Key Features:

- Structural Performance: Highest strength among the three alloys, suitable for load-bearing applications such as truck beds, machinery platforms, and aircraft components.

- Machinability: Easy to machine and weld, ideal for custom projects.

- Corrosion Resistance: Moderate corrosion resistance, suitable for general industrial use, but less ideal for marine environments without additional coating.

- Applications: Structural frameworks, automotive parts, and heavy-duty flooring requiring high rigidity.

Other Considerations

- Thickness-Specific Requirements: For 4mm plates, 6061-T6 is generally more suitable for structural integrity, while 5052-H32 performs better in corrosive environments. 3003-H22 is an economical choice for decorative or low-stress applications.

- Surface Finish: Anodizing or powder coating can enhance corrosion resistance and aesthetics, especially for 3003 and 5052.

- Standards: These alloys comply with international specifications such as ASTM B209 and GB/T 3618-2006, ensuring consistency in quality and performance.

Summary of Alloy Selection

| Alloy | Key Advantages | Ideal Applications |

| 3003 | Corrosion resistance, decorative finish | Truck toolboxes, architectural trim, signage |

| 5052 | Marine-grade corrosion resistance | Ship decks, refrigerated trucks, cold storage |

| 6061 | High strength, weldability | Truck beds, machinery platforms, structural framing |

By matching the alloy to the specific environment and load requirements, 4mm aluminium checker plates can deliver optimal performance in anti-slip flooring, transportation, and industrial settings.

Applications of 4mm Aluminium Checker Plate

- Flooring Solutions: Commonly used for flooring in commercial and industrial environments, such as warehouses, kitchens, and retail spaces, where durability and slip resistance are critical.

- Stair Treads and Platforms: Typically used for stair treads and platforms, providing a safe, slip-resistant surface for both indoor and outdoor environments.

- Decorative and Protective Wall Cladding: Used as decorative wall panels in commercial and residential buildings, offering protection while enhancing the visual appeal of the space.

- Equipment and Machinery Covers: Often used as protective covers for equipment and machinery, ensuring safety and durability in various industrial applications.

- Automotive and Transportation Applications: Due to its lightweight and sturdy characteristics, it is suitable for flooring and protective applications in truck beds, trailers, and other vehicles.